The hemmed furring channel & RC channels roll former with rolling punch is a specialized cold roll-forming machine designed to produce high-quality furring channels (hat channels) and resilient channels (RC channels) used in drywall, ceiling, and wall framing systems. This machine features an advanced hemming mechanism that creates a smooth, folded edge for improved structural integrity and safety, along with an integrated rolling punch unit for precise hole punching at specified intervals. Key Features: 1. Hemmed Edge Design – Produces furring channels with a clean, folded hem on the flanges, reducing sharp edges and enhancing durability. 2. Rolling Punch System – Automatically punches holes (round, oval, or slotted) at programmed intervals for easy fastening and seismic compliance. 3. High-Speed Production – Efficient roll-forming process with adjustable speed for consistent output. 4. Precision Roll Tooling – Customizable rolls to form various channel sizes (e.g., 7/8″, 1-1/2″, 2-1/2″) with tight tolerances. 5. Material Compatibility – Works with galvanized steel, pre-painted steel, or other metal coils (typically 20-26 gauge). 6. Automated Cutting – Hydraulic or servo-driven cutoff for accurate length control. 7. PLC Control System – User-friendly interface for easy adjustment of punching patterns, length, and speed. Applications: — Drywall Framing – Creates hat channels for ceilings and walls. — Resilient Sound Isolation – Produces RC channels for noise reduction in commercial and residential buildings. — HVAC & Electrical Support – Used for mounting ductwork and conduit. This machine ensures high efficiency, precision, and safety in manufacturing furring and resilient channels, making it ideal for metal framing manufacturers and construction material suppliers.

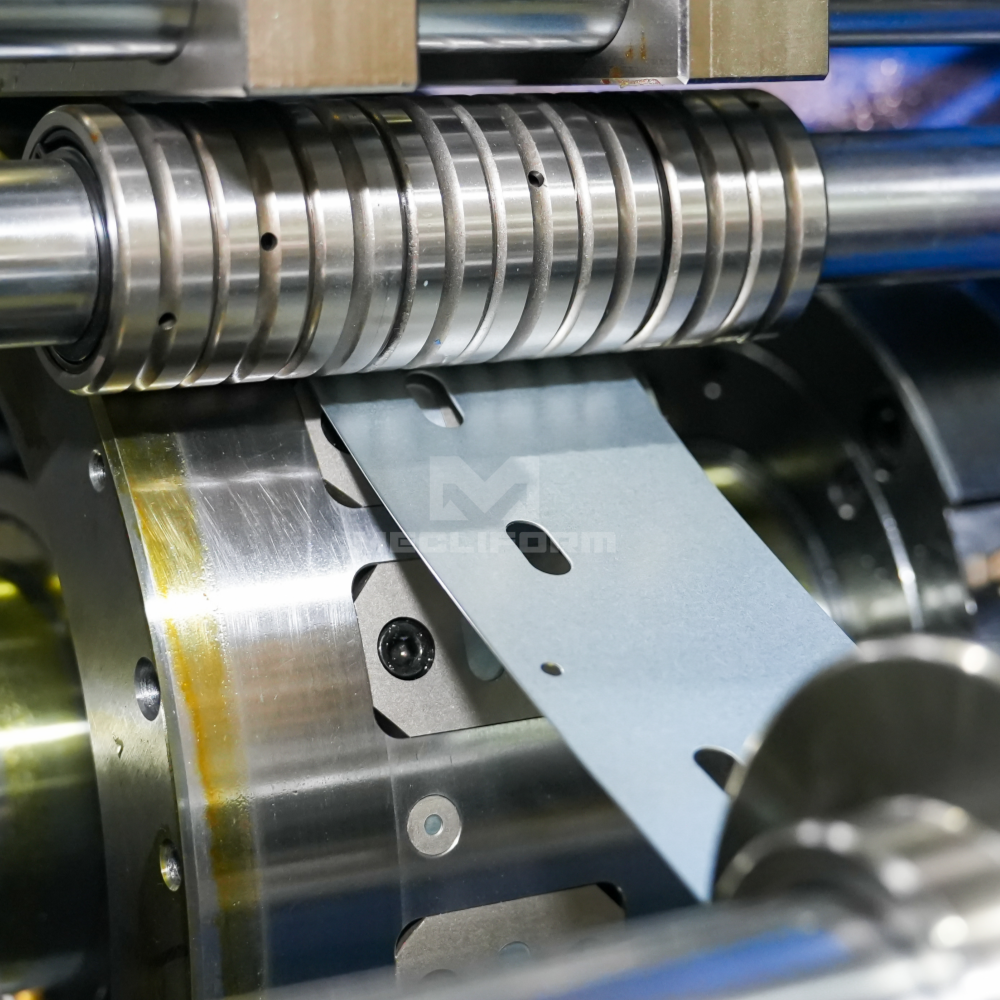

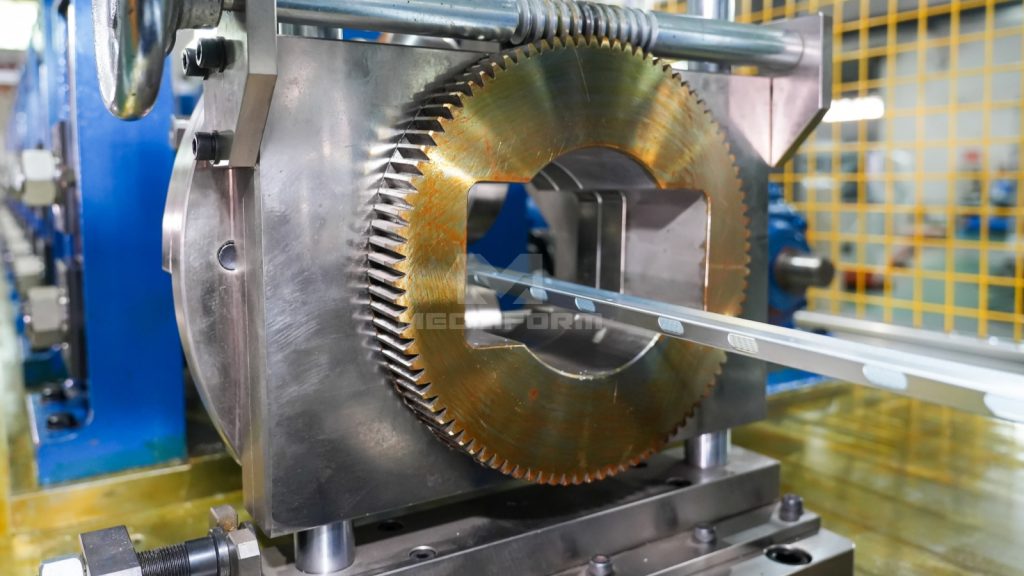

Rolling Punching unit is a process in which a rotating roller with specially designed features to create holes in a sheet of material. Roller punching is efficient, precise, and can be easily automated for high-volume production.

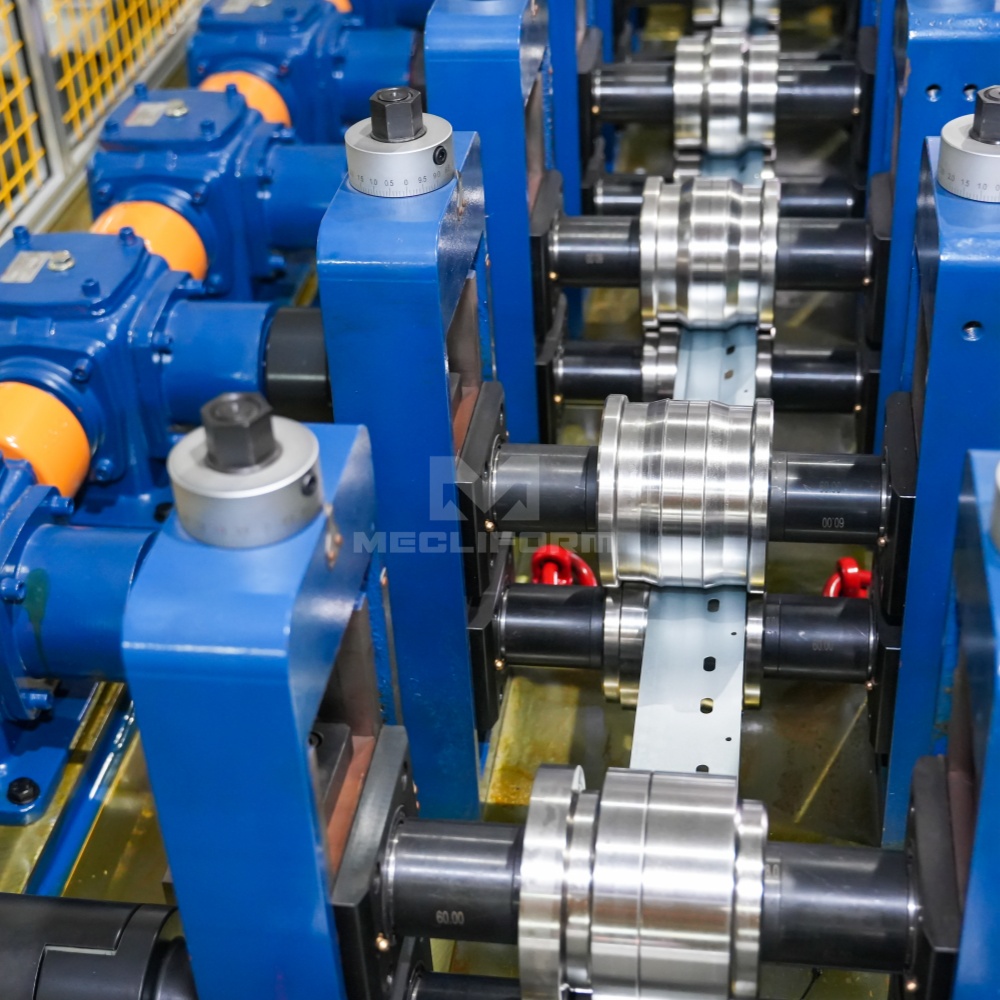

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type.

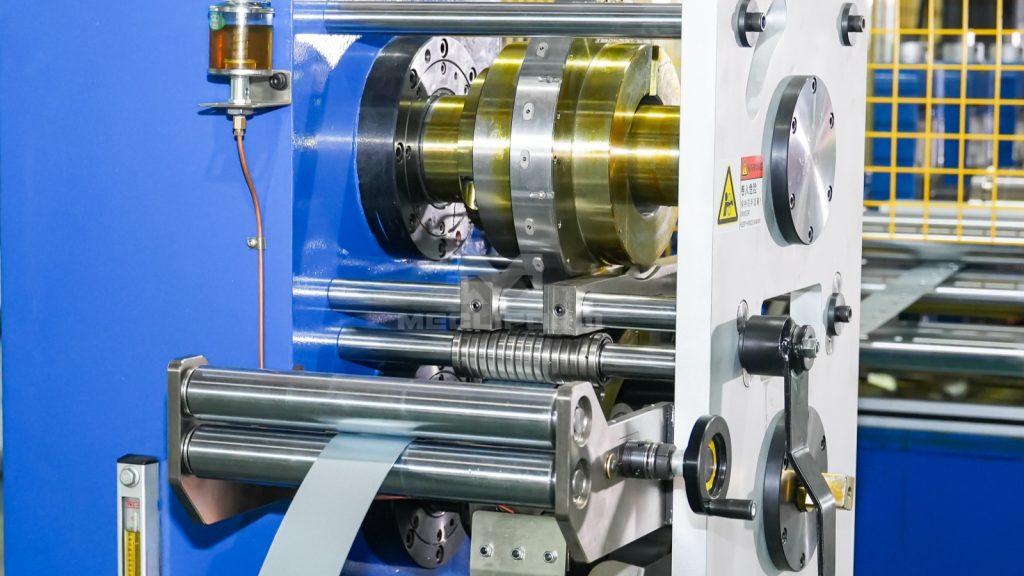

Flying cut unit is used in industrial settings to continuously cut materials without interruptions. This unit is designed to operate without pauses, allowing for efficient and fast cutting of metal sheets.

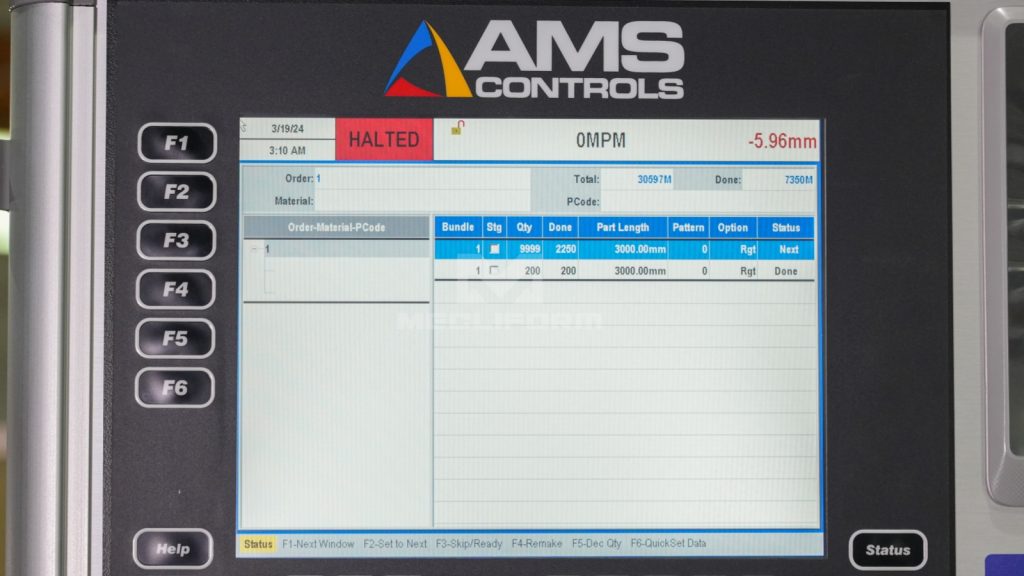

AMS control system can control lighting, heating and cooling systems, security cameras, and access control, among other features. It can also generate reports and alerts to help facility managers identify issues and make informed decisions.