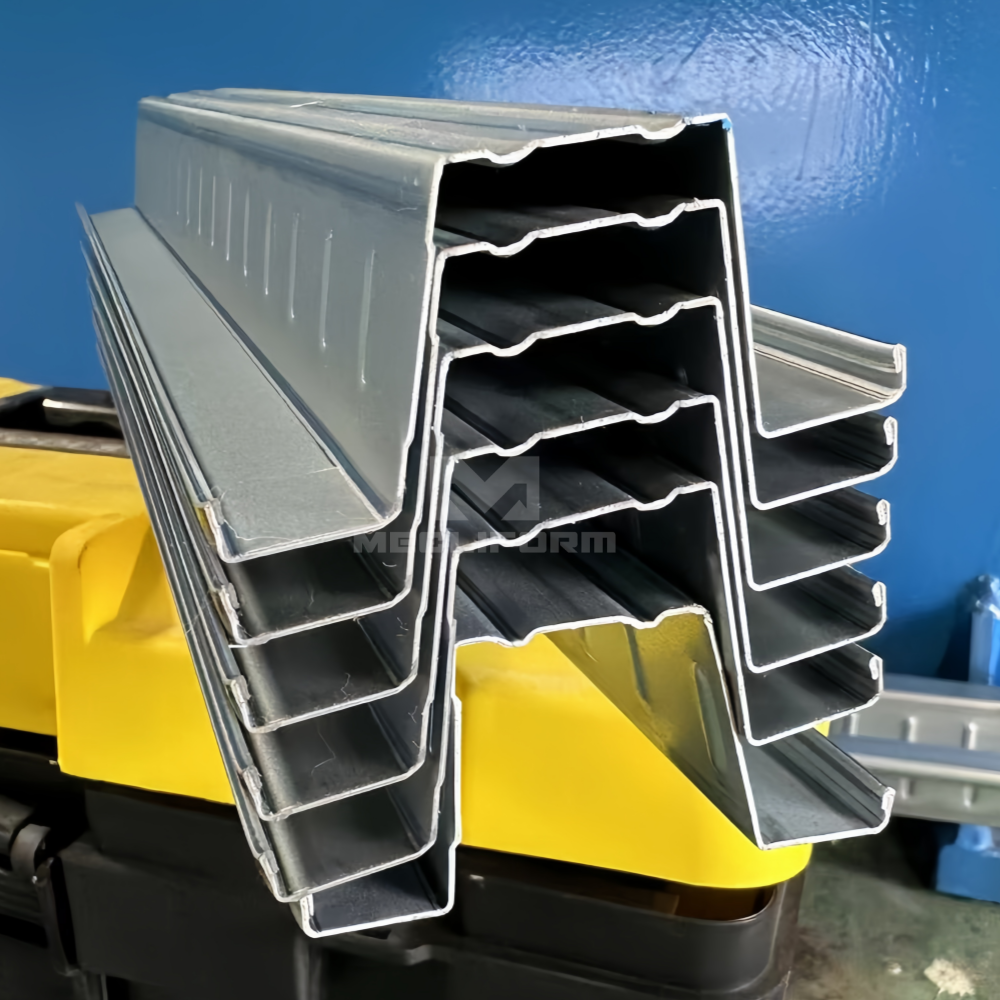

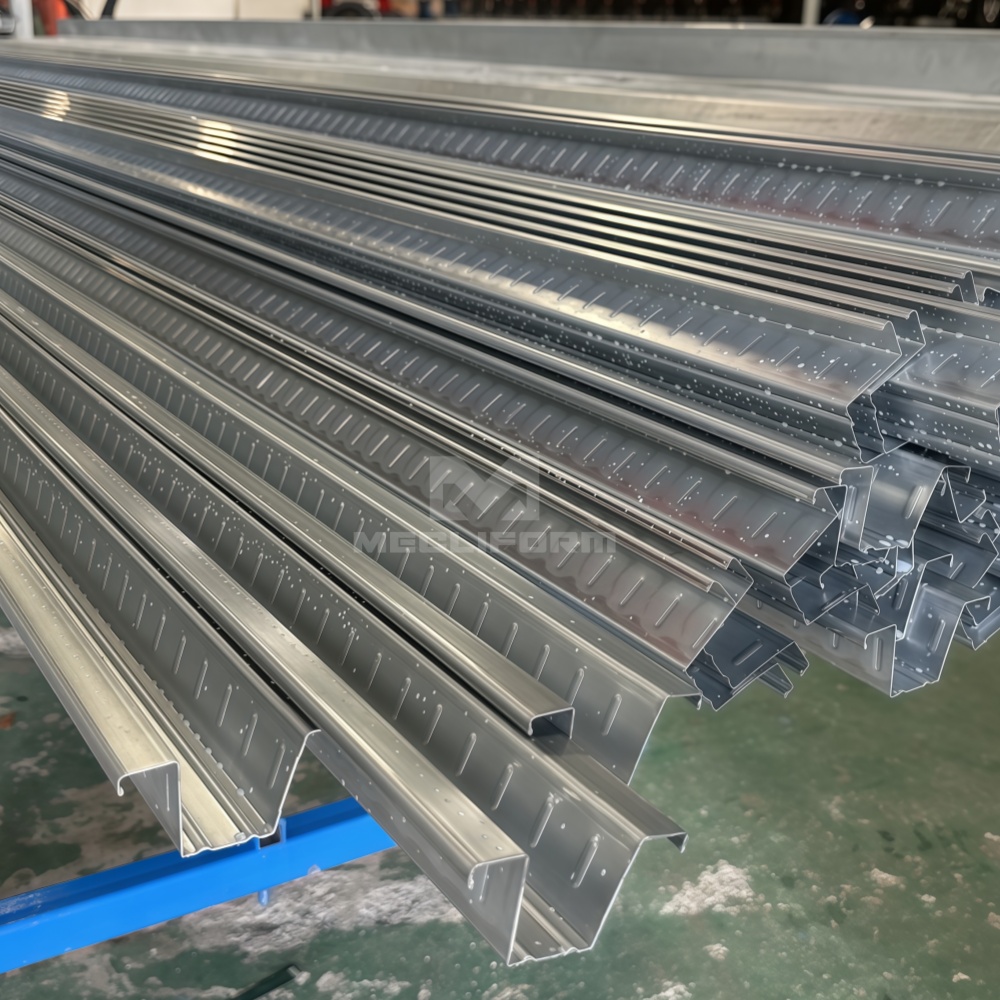

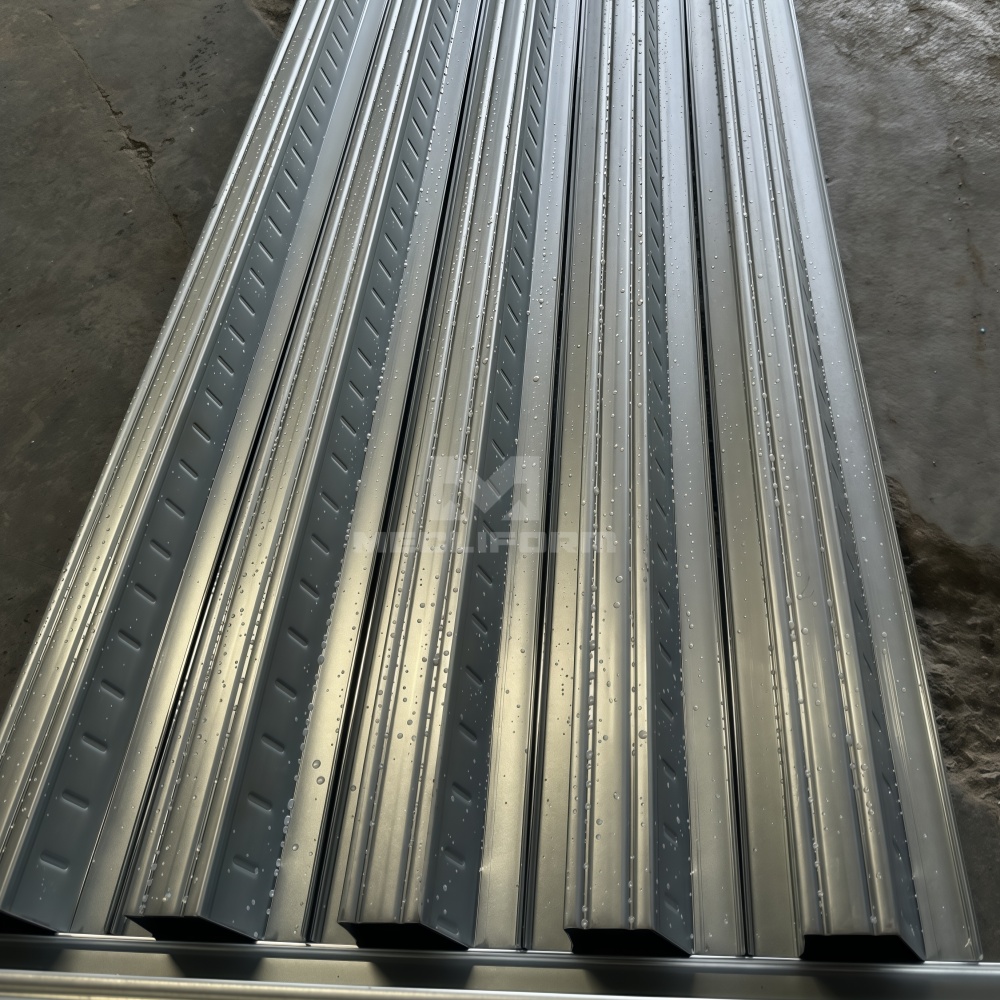

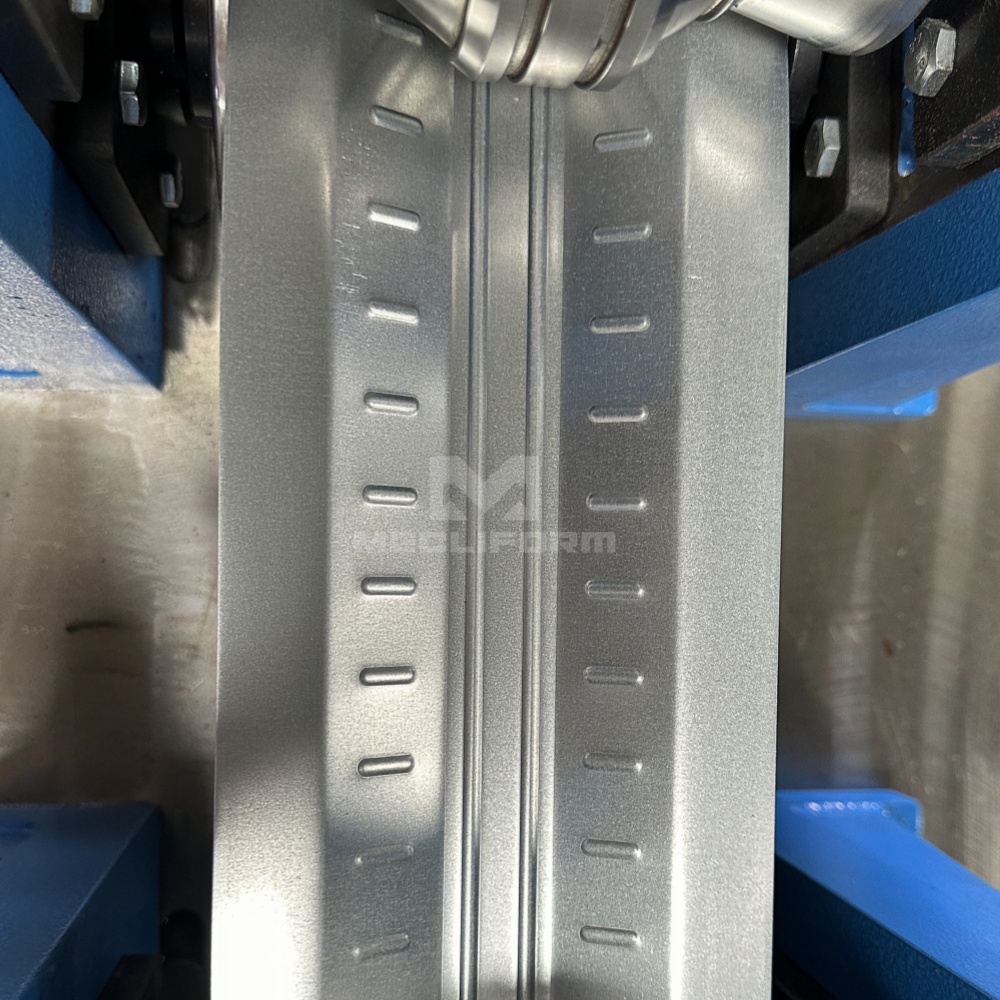

Metal roof battens are lightweight, durable strips typically made from galvanized steel, aluminum, or other corrosion-resistant metals. They are installed horizontally or vertically over roof rafters or trusses to provide a secure fixing point for roofing materials such as metal sheets, tiles, or composite panels. Metal ceiling battens (also called furring channels or hat channels) are thin, rigid strips made from galvanized steel or aluminum. They are fixed to the underside of ceiling joists or concrete slabs to create a level framework for attaching plasterboard, acoustic panels, or other ceiling finishes. Battens are installed over rafters/trusses or under joists/concrete slabs.

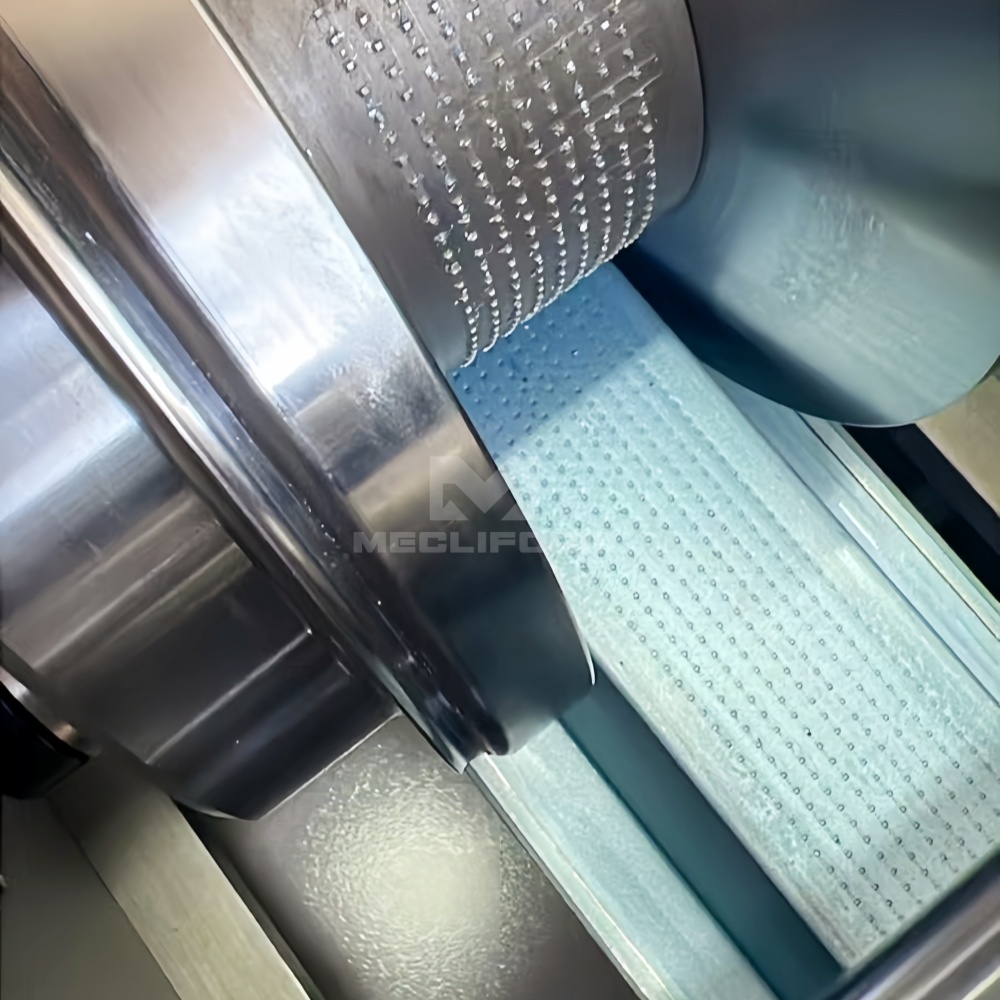

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type.

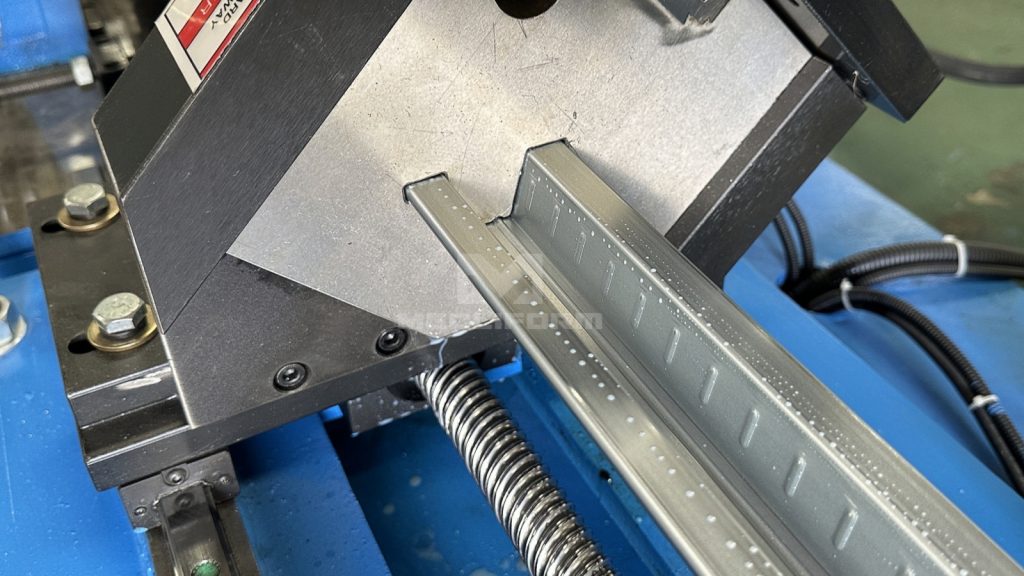

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.