Our storage and logistics machinery includes roll formers designed to produce shelving, racking, and other storage solutions for warehouses, distribution centers, and manufacturing facilities. These machines are built to withstand heavy use and deliver precise, consistent results. These machines are versatile and can be easily adjusted to create different profiles and sizes to meet specific project requirements.

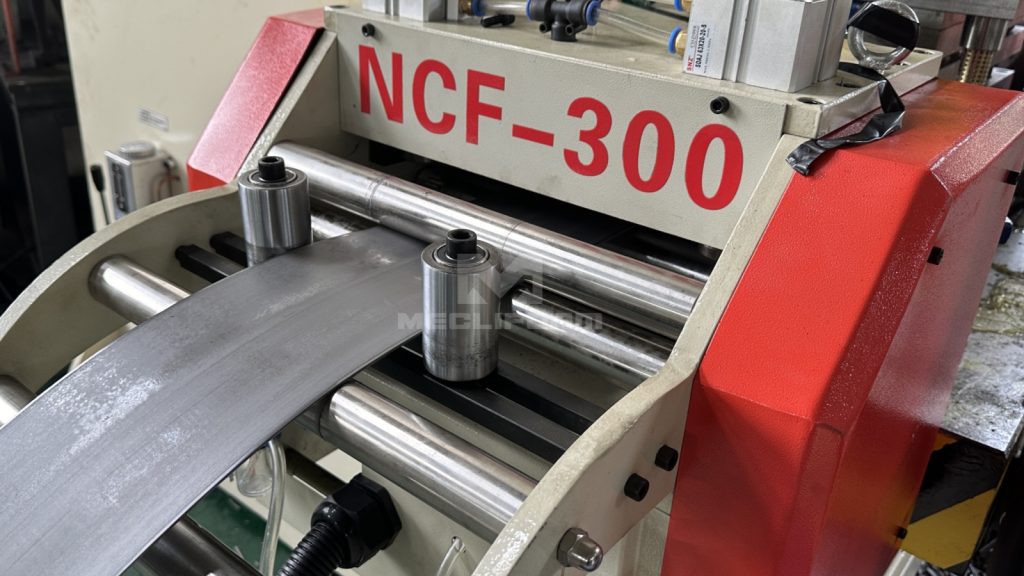

Servo feeder is a type of automated feeding system that is used in manufacturing processes to accurately and precisely deliver strips to the press. It consists of a servo motor, a control system, and a feeding mechanism that can be adjusted to control the speed, direction, and amount of strips being fed.

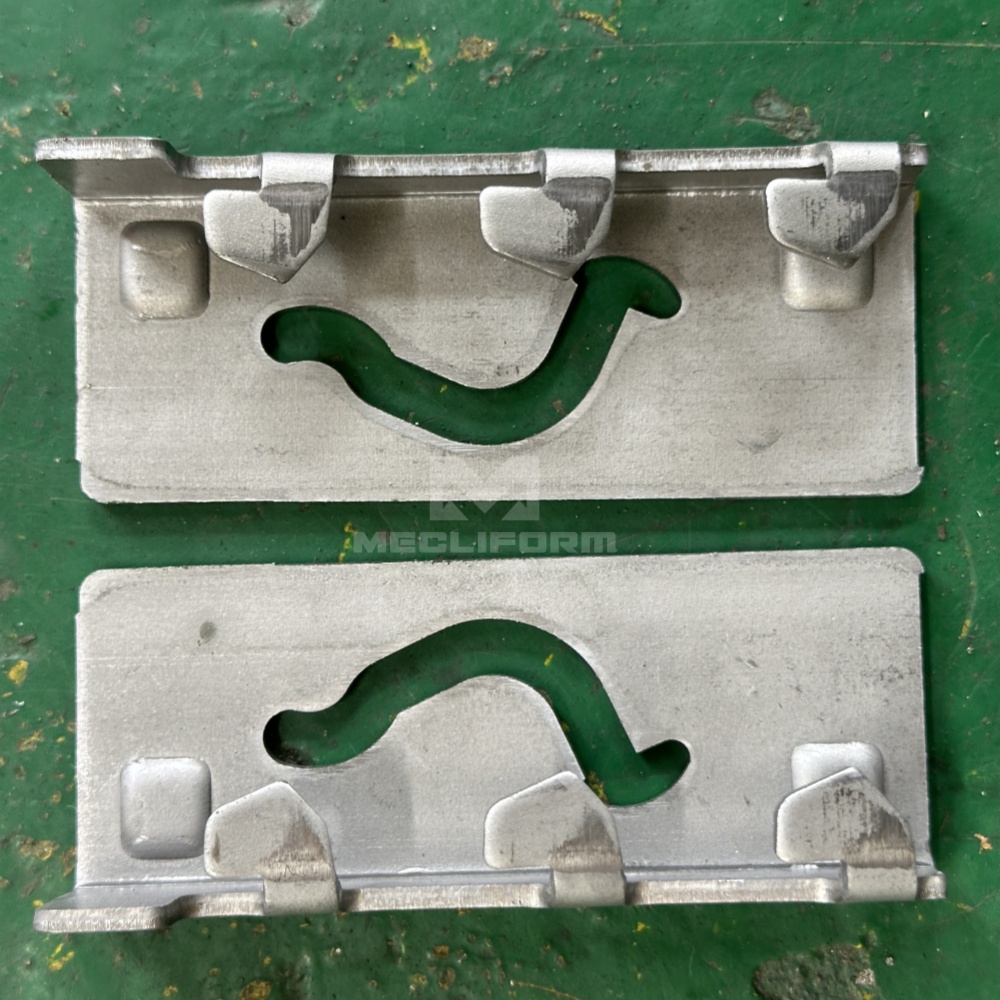

Progressive die is designed with multiple stations to perform cutting, bending, and forming operations on a metal sheet as it progresses through the press. Each station is equipped with a different set of cutting or forming tool that work together in a synchronized manner to produce the L bars.

Discharger (2 pcs/stroke) is used to release or unload the finished L bar, left and right pieces together dropping.