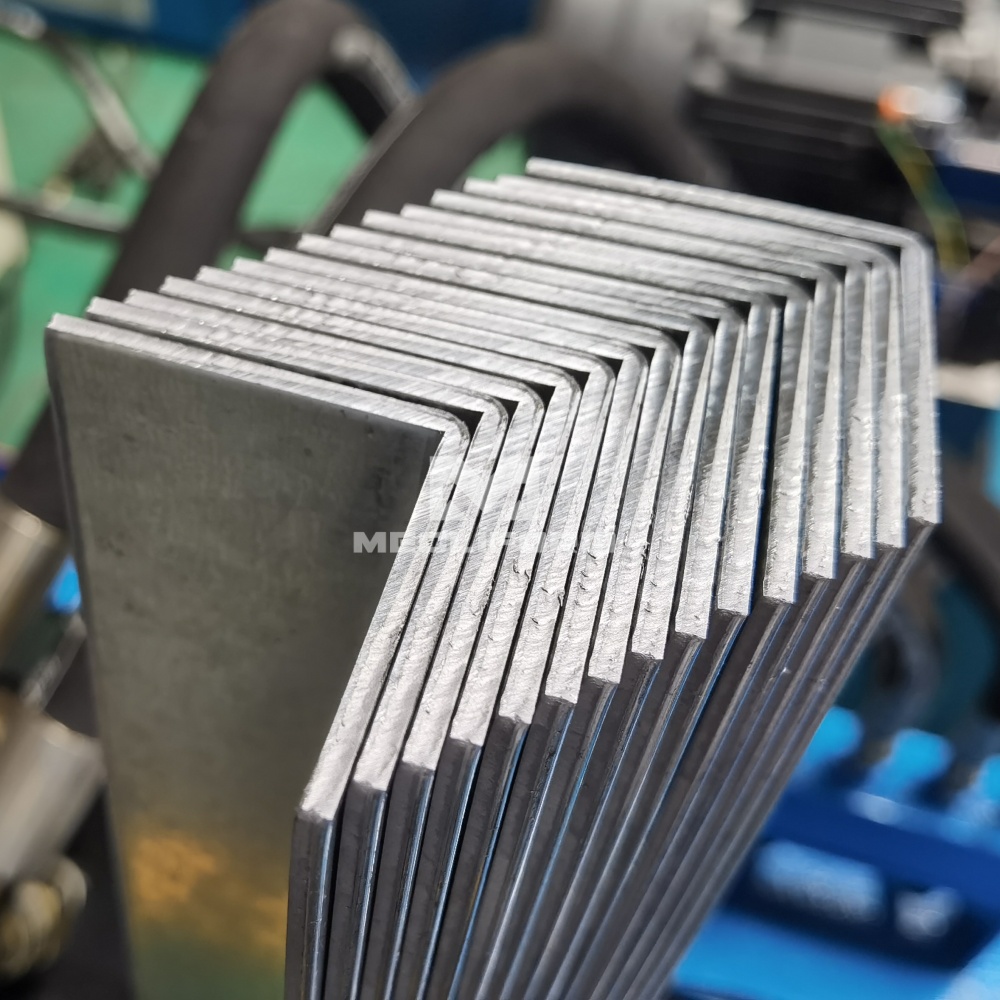

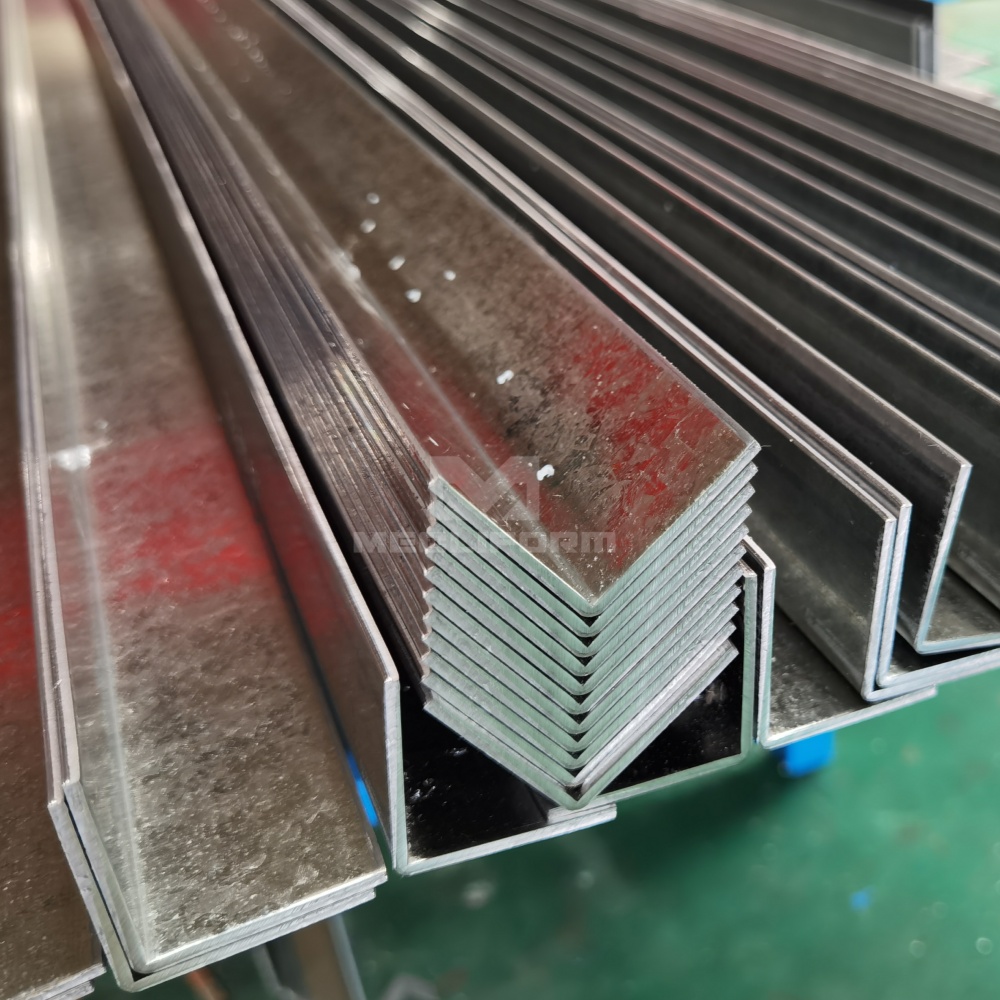

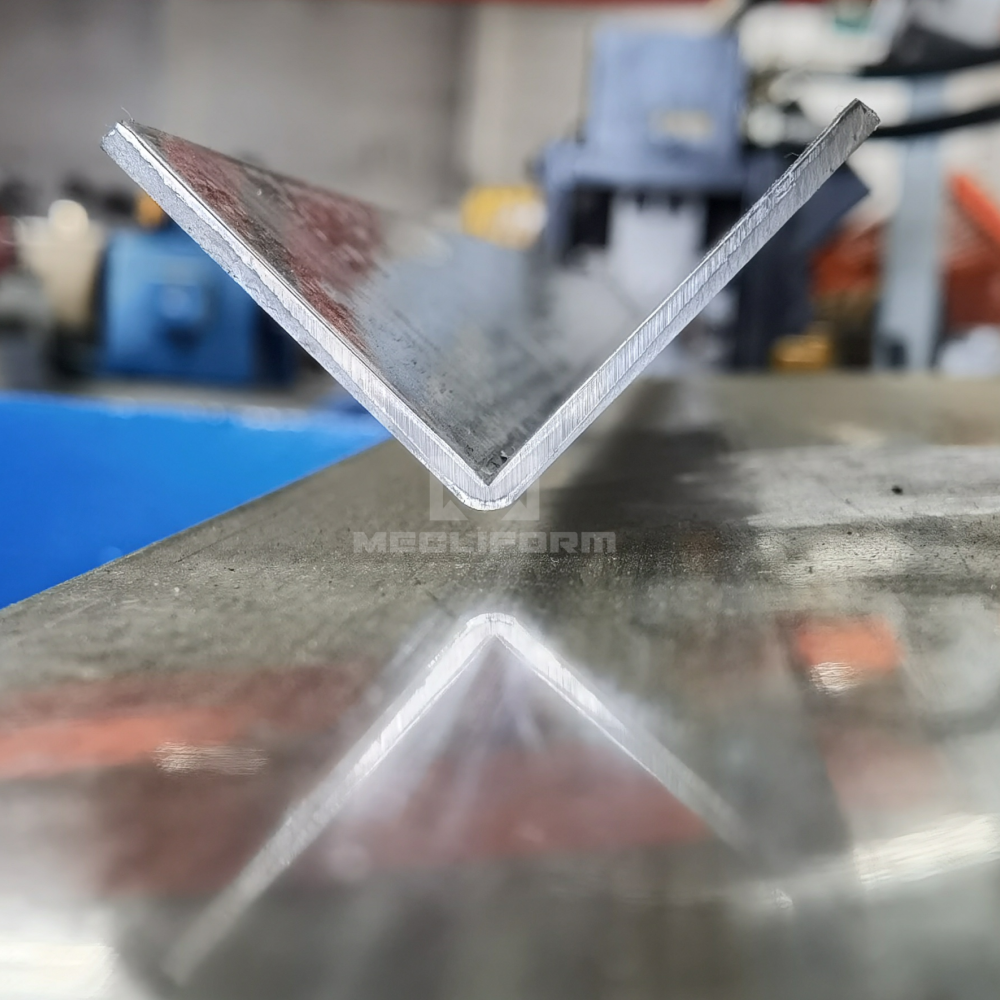

The L angle roll former is a specialized metal forming machine designed to produce L-shaped angle profiles (equal or unequal legs) from coiled or sheet metal. It uses a series of sequentially arranged rollers to progressively bend the metal strip into the desired angle shape through a continuous cold-forming process.

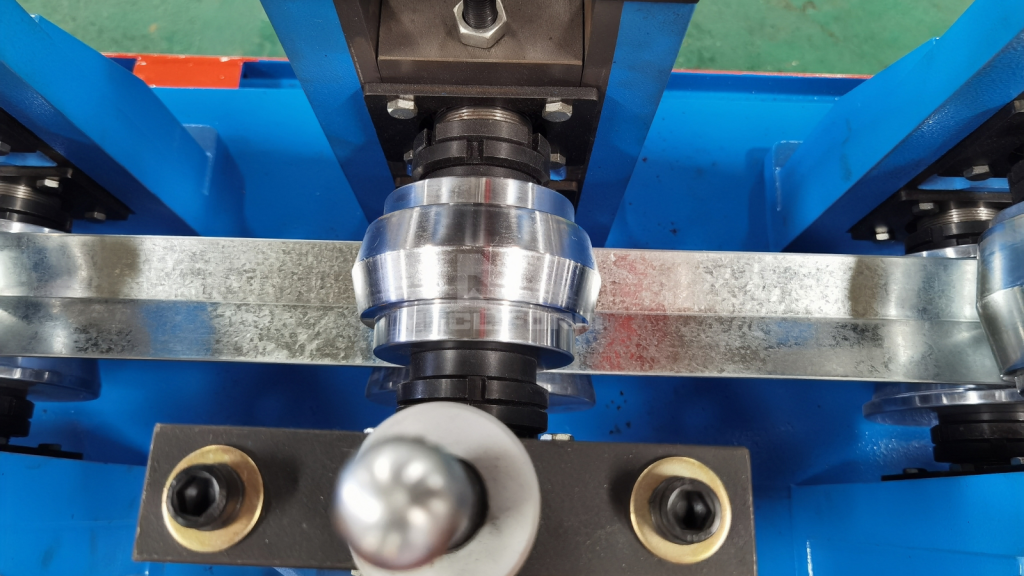

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.