Our storage and logistics machinery includes roll formers designed to produce shelving, racking, and other storage solutions for warehouses, distribution centers, and manufacturing facilities. These machines are built to withstand heavy use and deliver precise, consistent results. These machines are versatile and can be easily adjusted to create different profiles and sizes to meet specific project requirements.

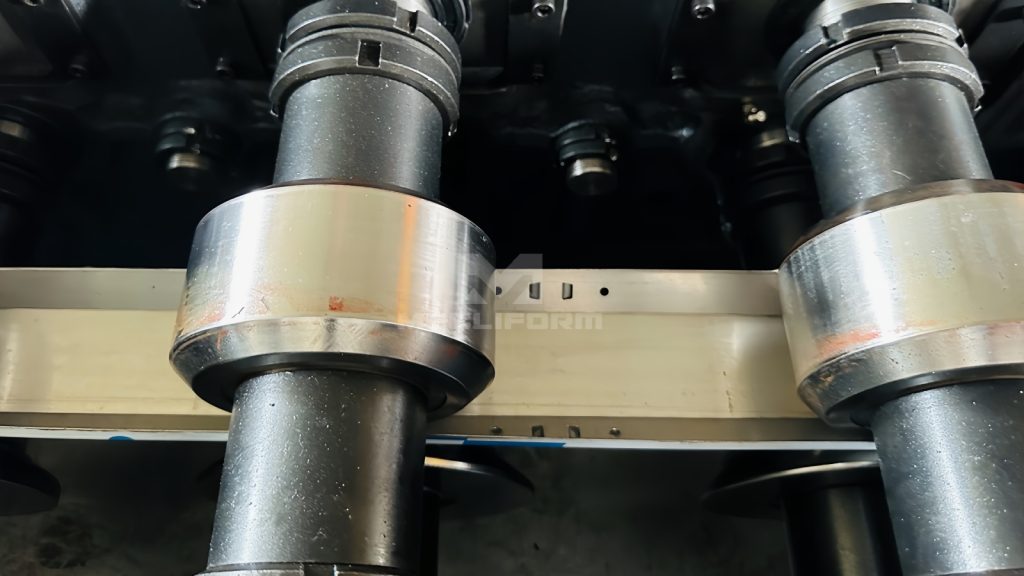

Upright roll former is used to produce stainless steel slotted upright for simple rack. It typically consists of decoiler, leveler, pre-punching unit, roll forming machine and cutting unit.

Cross beam roll former is used to produce stainless steel slotted upright for simple rack. It typically consists of decoiler, leveler, pre-punching unit, roll forming machine and cutting unit.

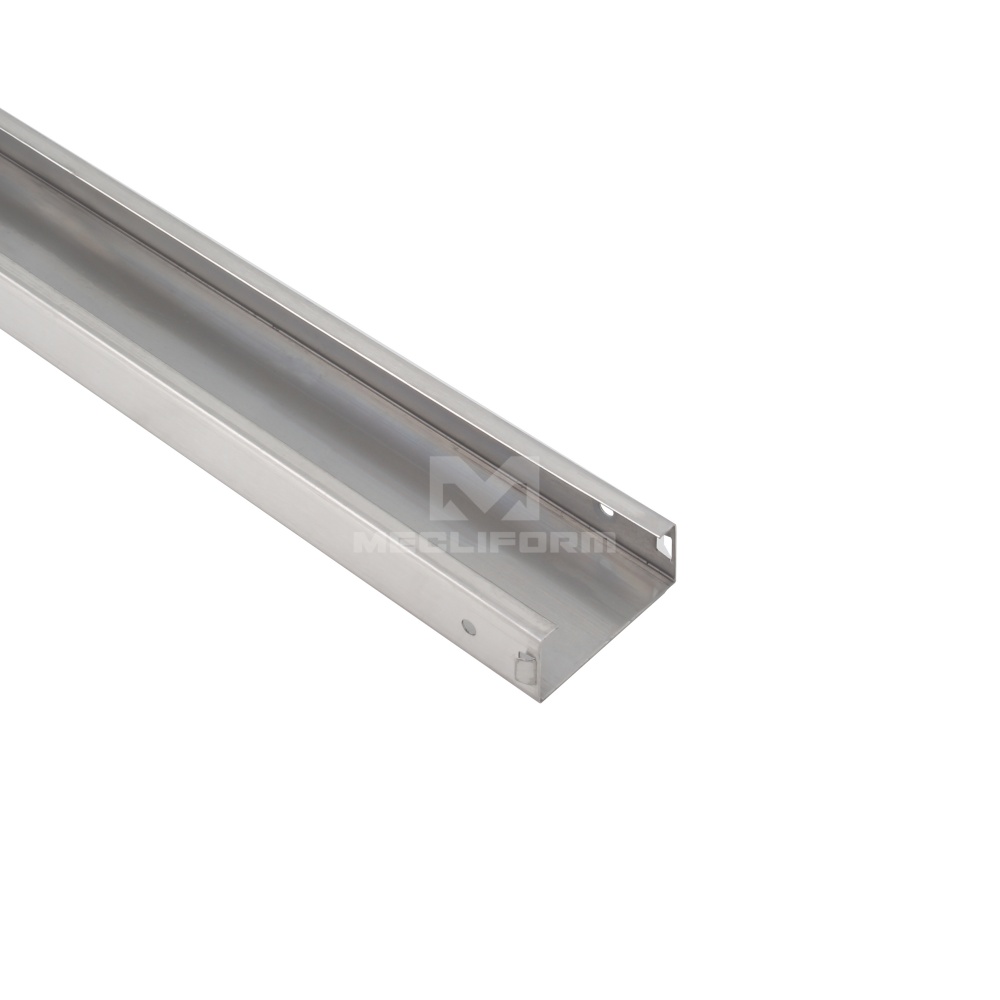

Middle beam roll former is used to produce stainless steel slotted upright for simple rack. It typically consists of decoiler, leveler, pre-punching unit, roll forming machine and cutting unit.

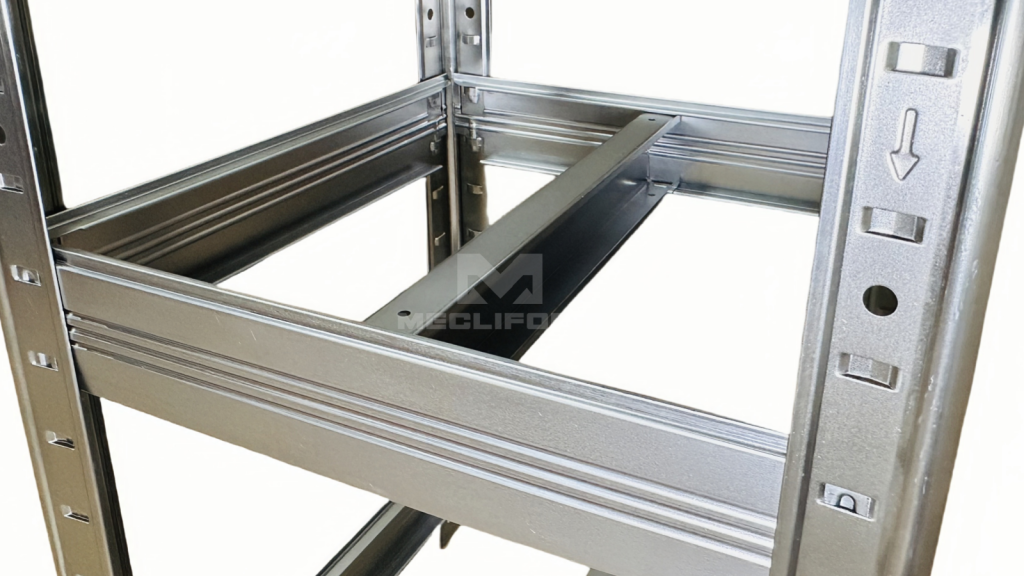

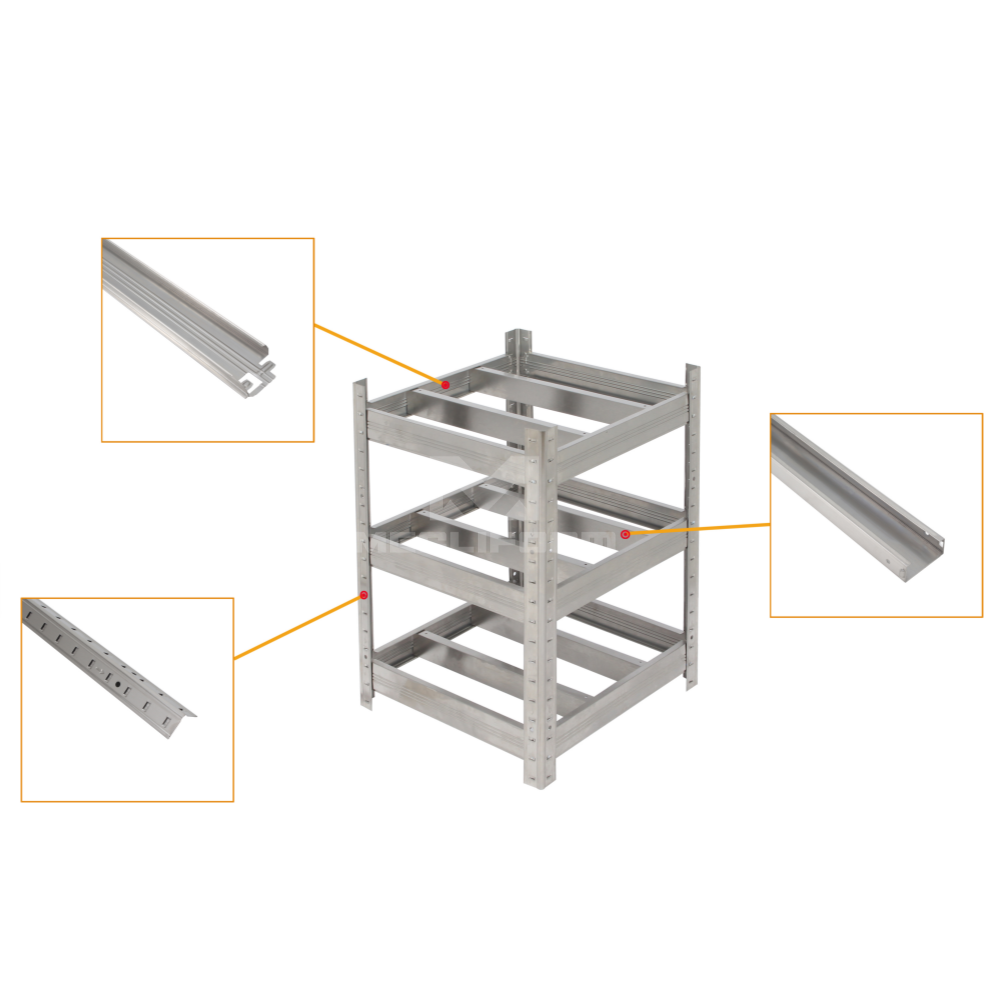

Simple rack assembly as photo is without bolts. Upright, cross beam and middle beam are slotted together, easy and user friendly. it’s convenient for consumers to bring home and assembly themselves without tools.