A CZ purlin roll forming machine is an advanced industrial machine designed to manufacture C-purlins (Cee sections) and Z-purlins (Zee sections) from coiled steel sheets. These machines use a cold roll-forming process to shape metal into precise structural sections with high efficiency and consistency. it consists of material feeding system, roll former with adjustable rollers allow for different purlin sizes (e.g., 100mm, 150mm, 200mm), punching & notching Unit (optional) and cutting unit (e.g., 6m, 8m, 12m). Normally material thickness is 1.0~3.0mm, purlin depth 80~300mm (adjustable). It’s adjustable for different purlin sizes and hole patterns. It is applied in steel structure buildings (Warehouses, Factories, Aircraft Hangars), roofing & wall framing systems, solar panel mounting structures, and agricultural & industrial sheds.

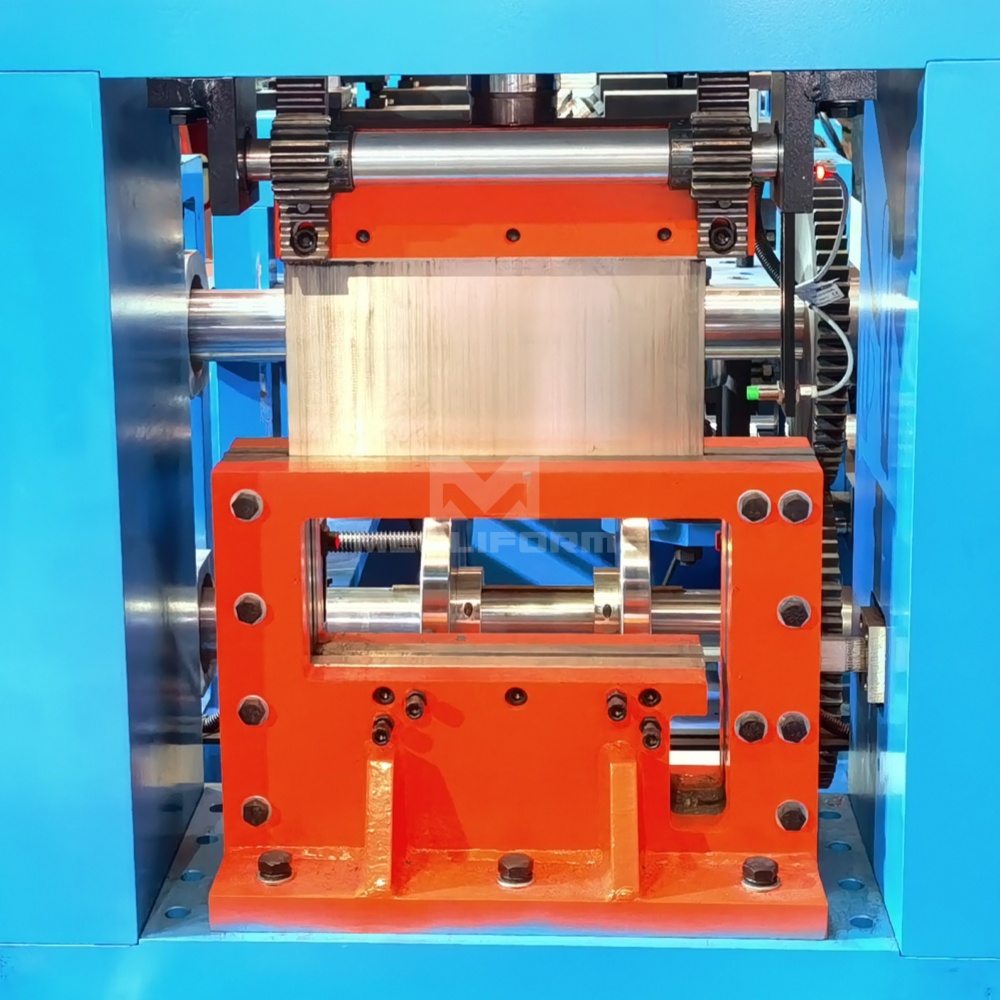

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

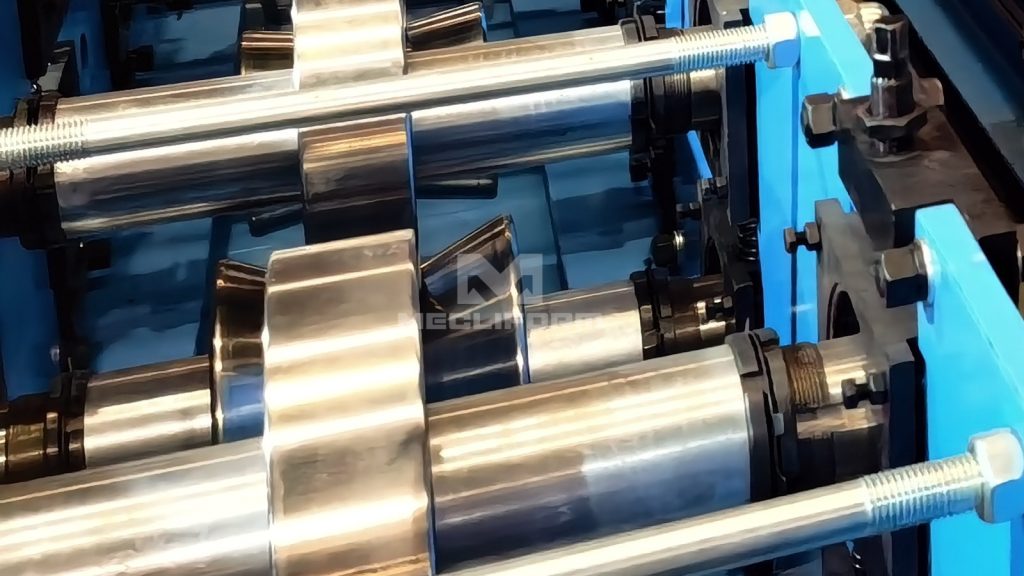

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

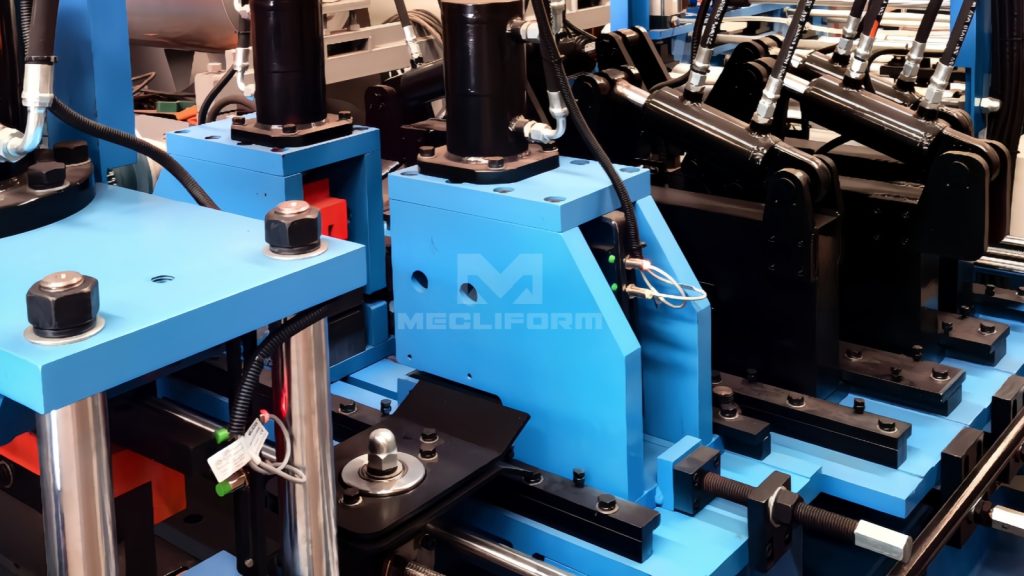

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.