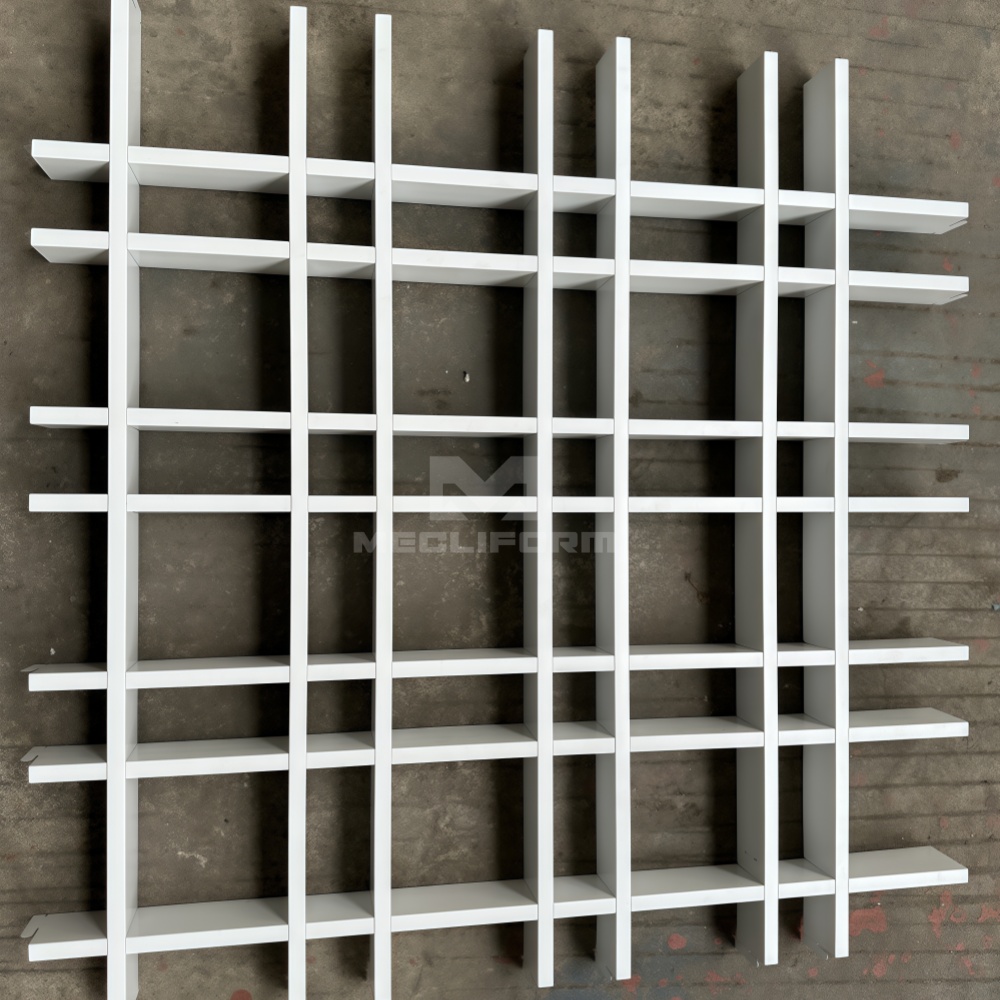

Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs. These machines are equipped with advanced features for cutting, forming, and finishing tiles with precision and efficiency. It’s also available to add a cleaning unit between roll former and conveyer after cutting, to remove the lubricant oil on the strip surface.

Punching and Cutting unit is used to punch holes and cut into pieces before roll forming. It typically consists of punching and cutting tools that are propelled with force through the material to create the desired hole or length.

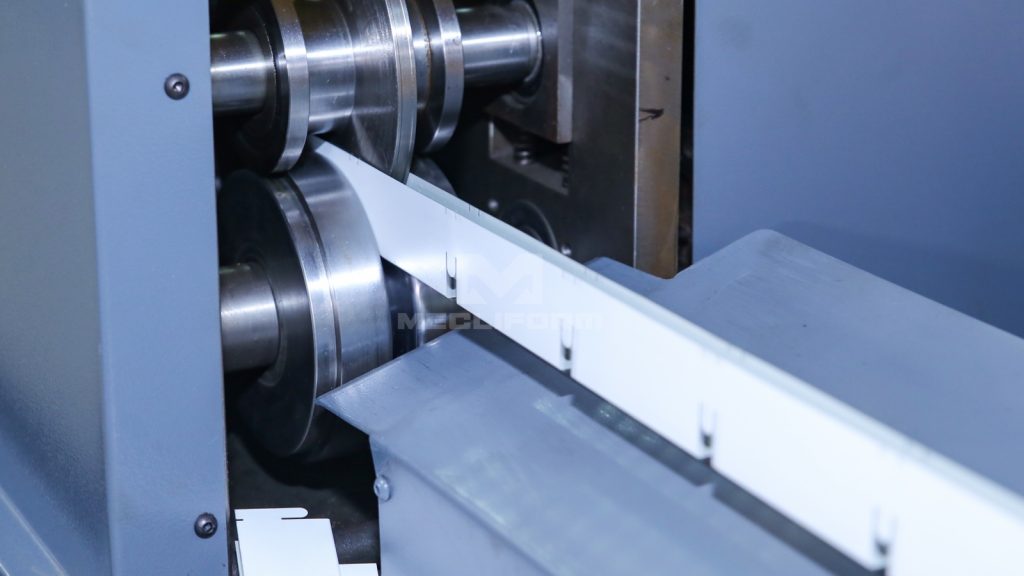

Roll former is used to create uniform, continuous bends in metal strips. It works by passing a strip through a series of rollers that gradually bend and form it into desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type, or width adjustable type.

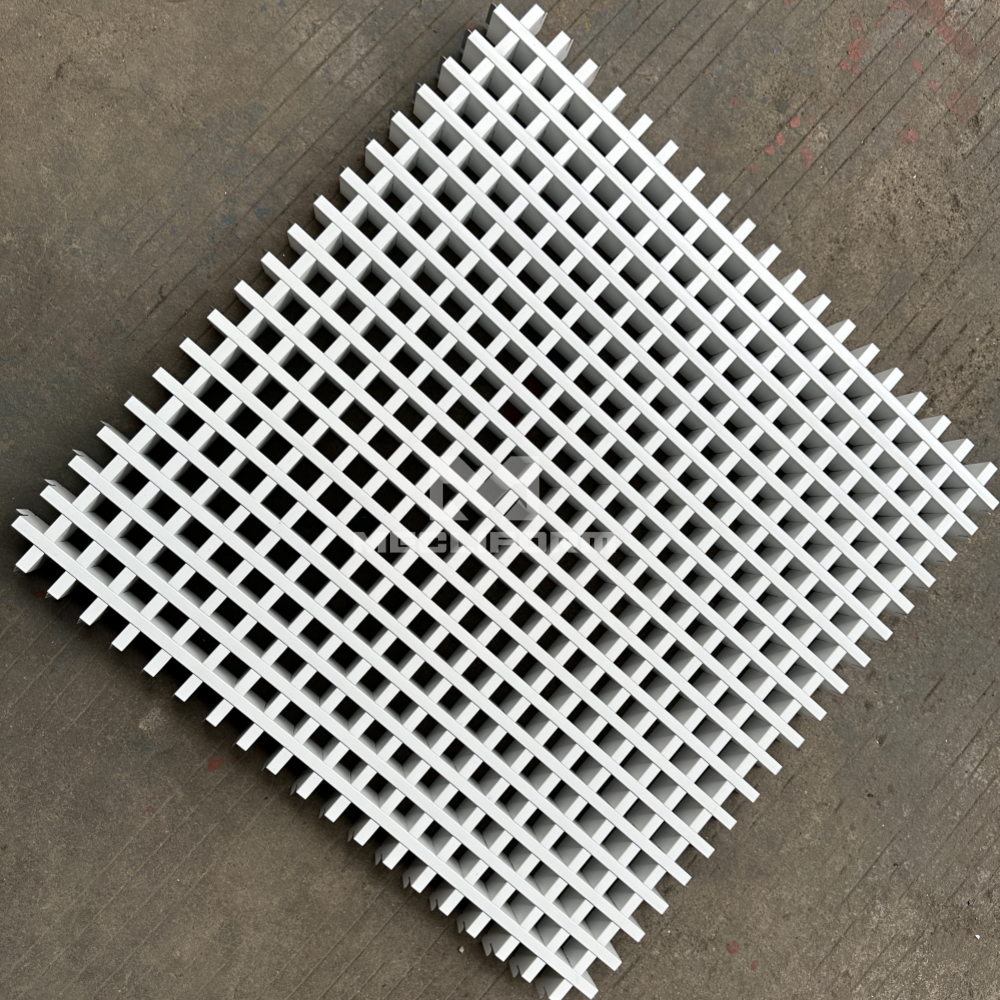

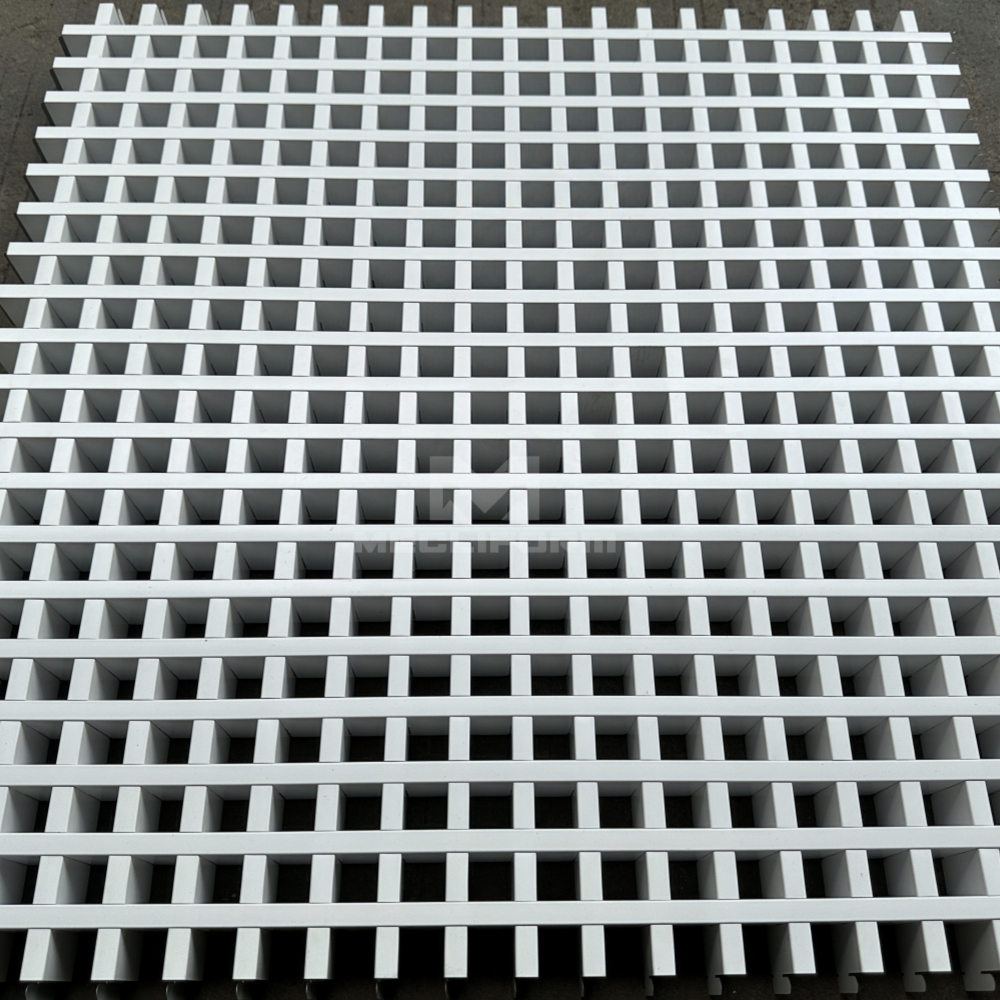

Discharger is a mechanism used to safely and efficiently release the grille ceiling profiles from roll former.