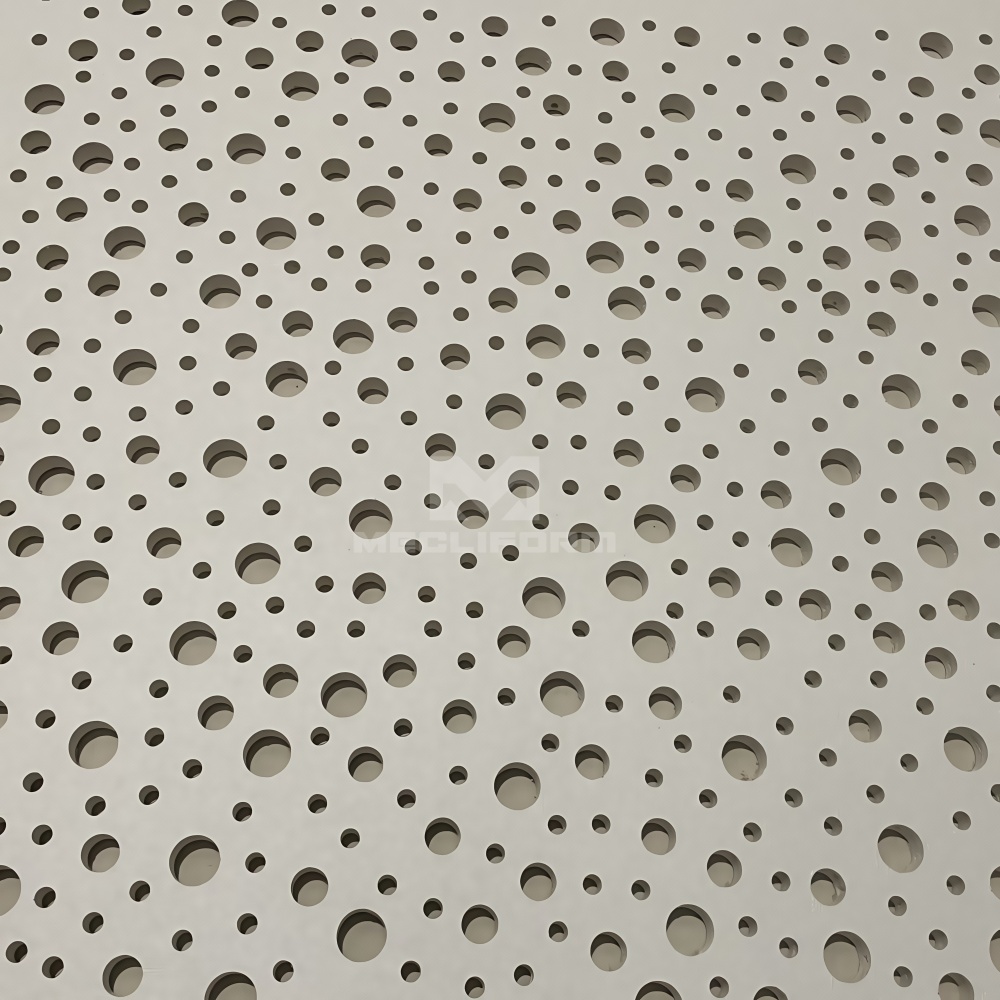

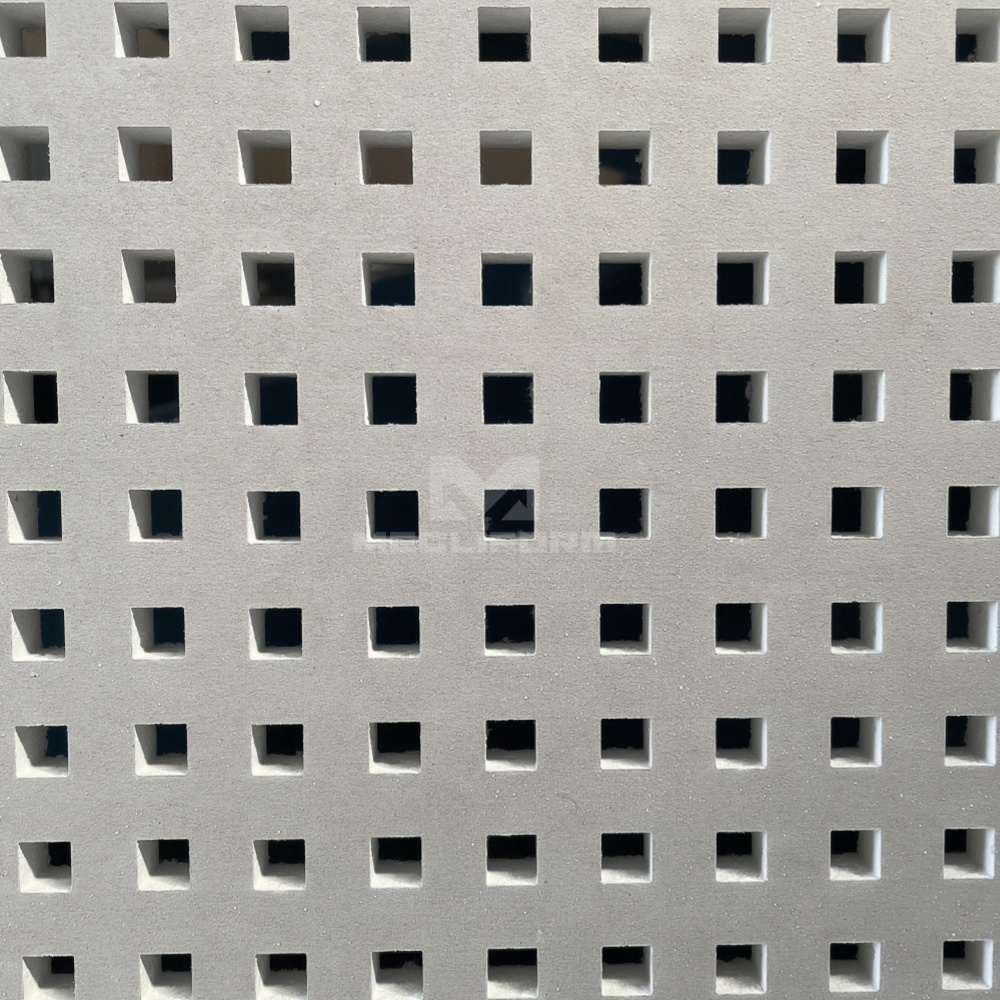

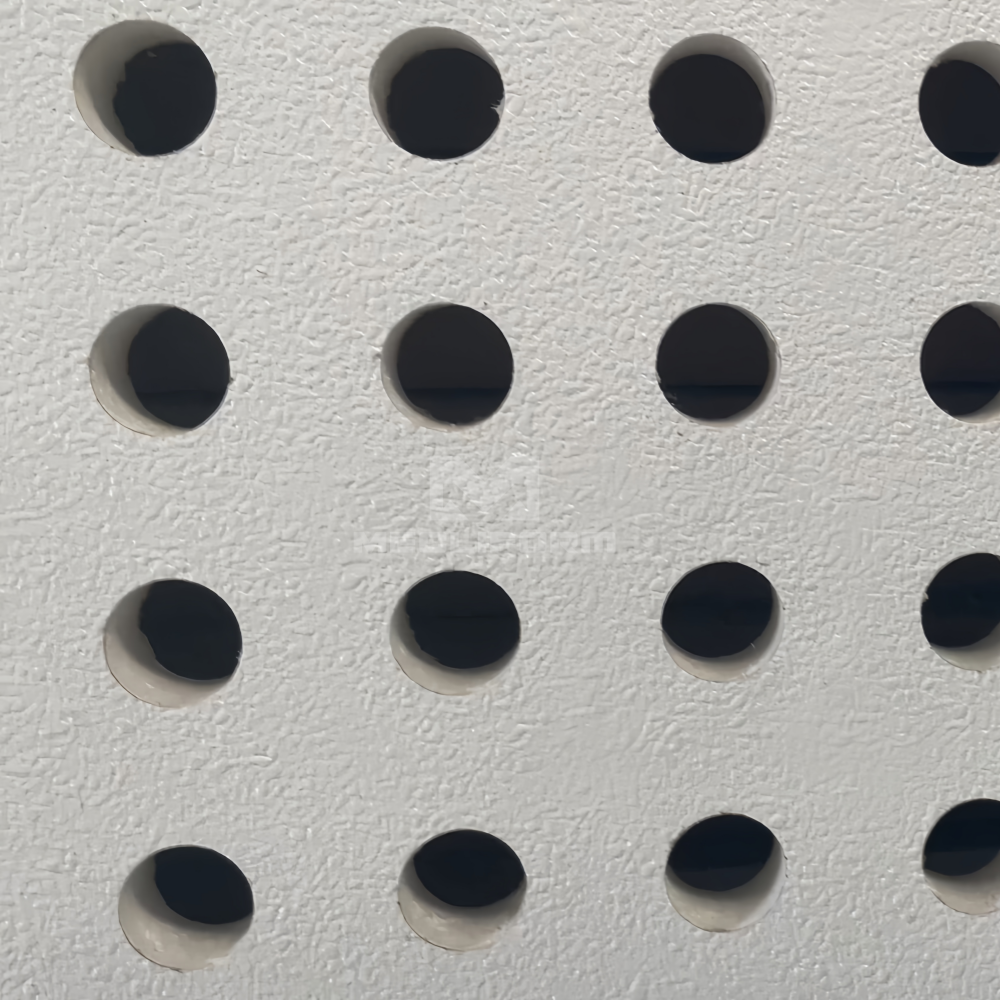

A gypsum board perforation line is an automated production system designed to create precise perforations (holes or patterns) in gypsum boards (also known as drywall or plasterboard) for acoustic, aesthetic, or functional purposes. These perforations enhance sound absorption, reduce weight, or improve aesthetics in architectural applications such as ceilings, wall panels, and partitions. Key components of a gypsum board perforation line includes feeding system – automatically loads and positions raw gypsum boards onto the production line; conveyor system – transports boards through different stages of the perforation process; punching unit – uses CNC-controlled punching heads to create uniform holes or patterns; dust extraction system – removes gypsum dust generated during perforation to maintain a clean working environment; stacking system – automatically collects and stacks perforated boards for packaging.

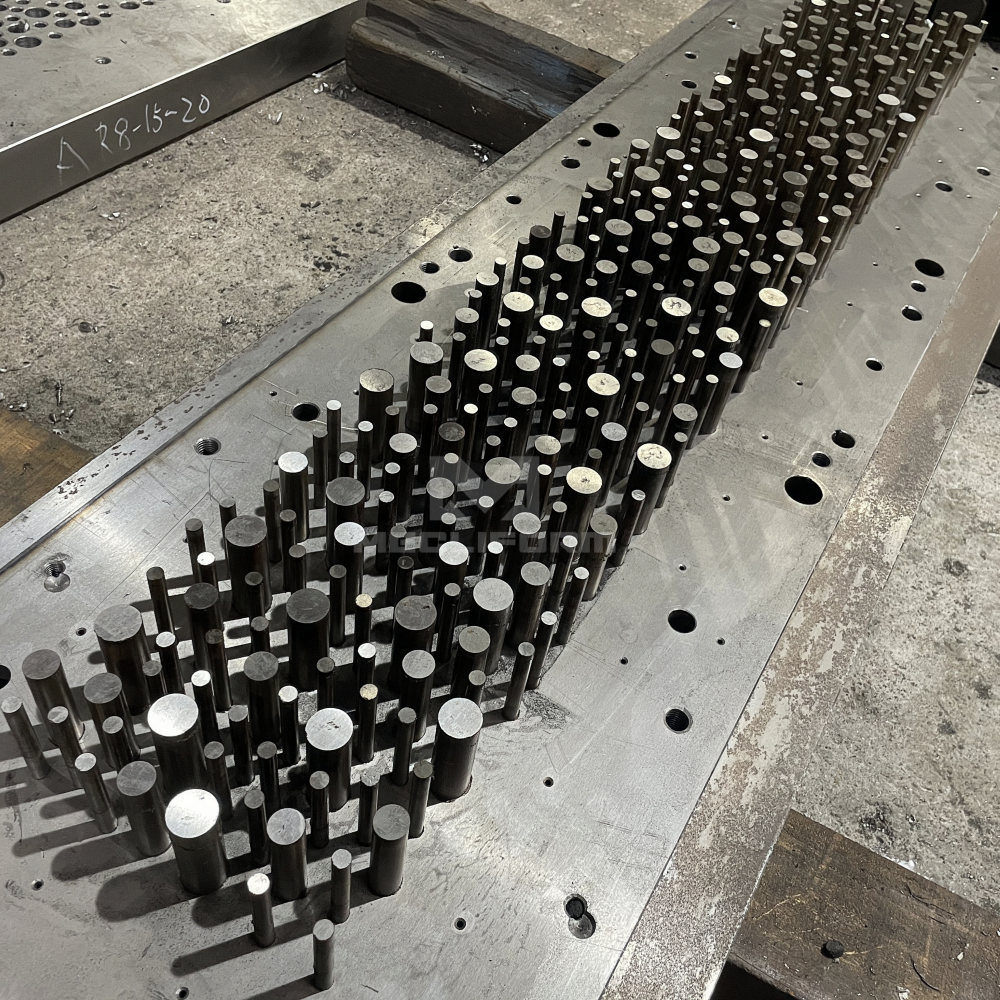

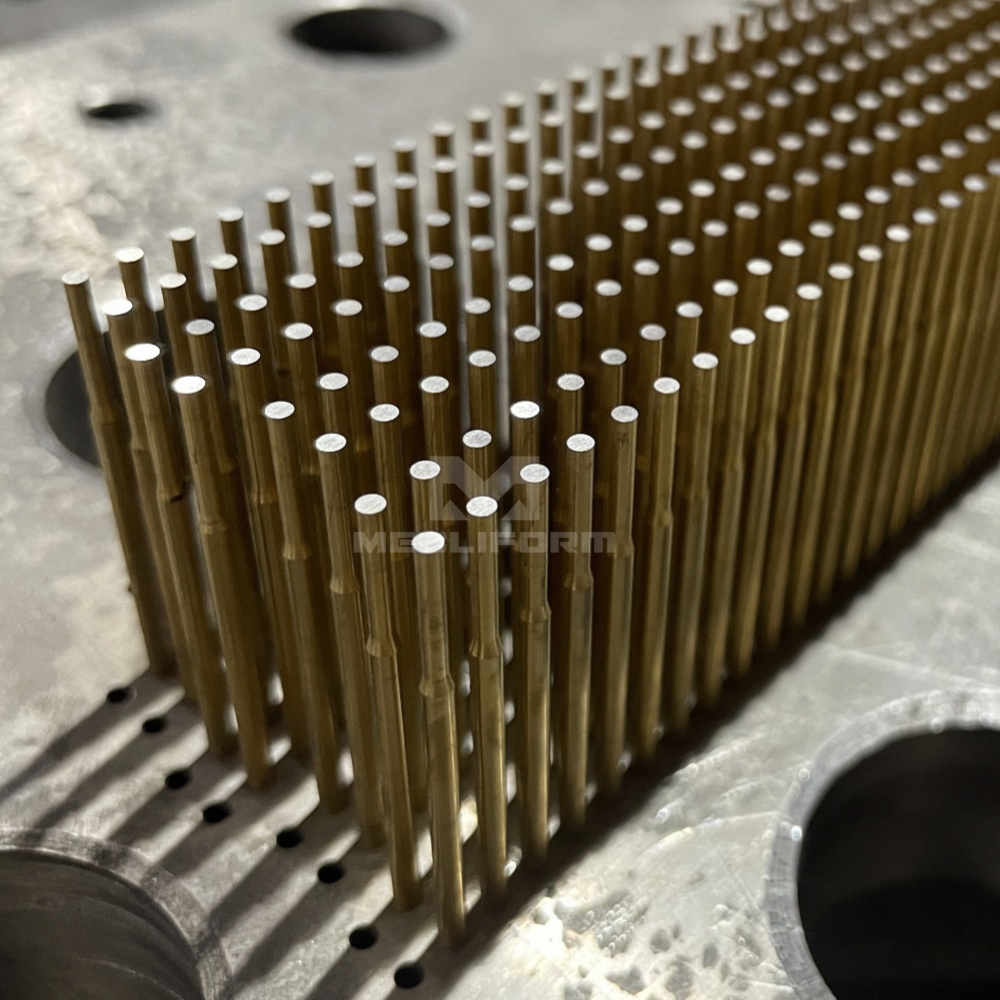

Perforation unit including feeding system is used to create uniform holes or patterns. It typically consists of a metal tool that is propelled with force through the material to create the desired holes.

Perforation tool is a specialized device designed to create precise holes, slots, or perforations in drywall (gypsum board) for various construction, acoustic, and decorative purposes.