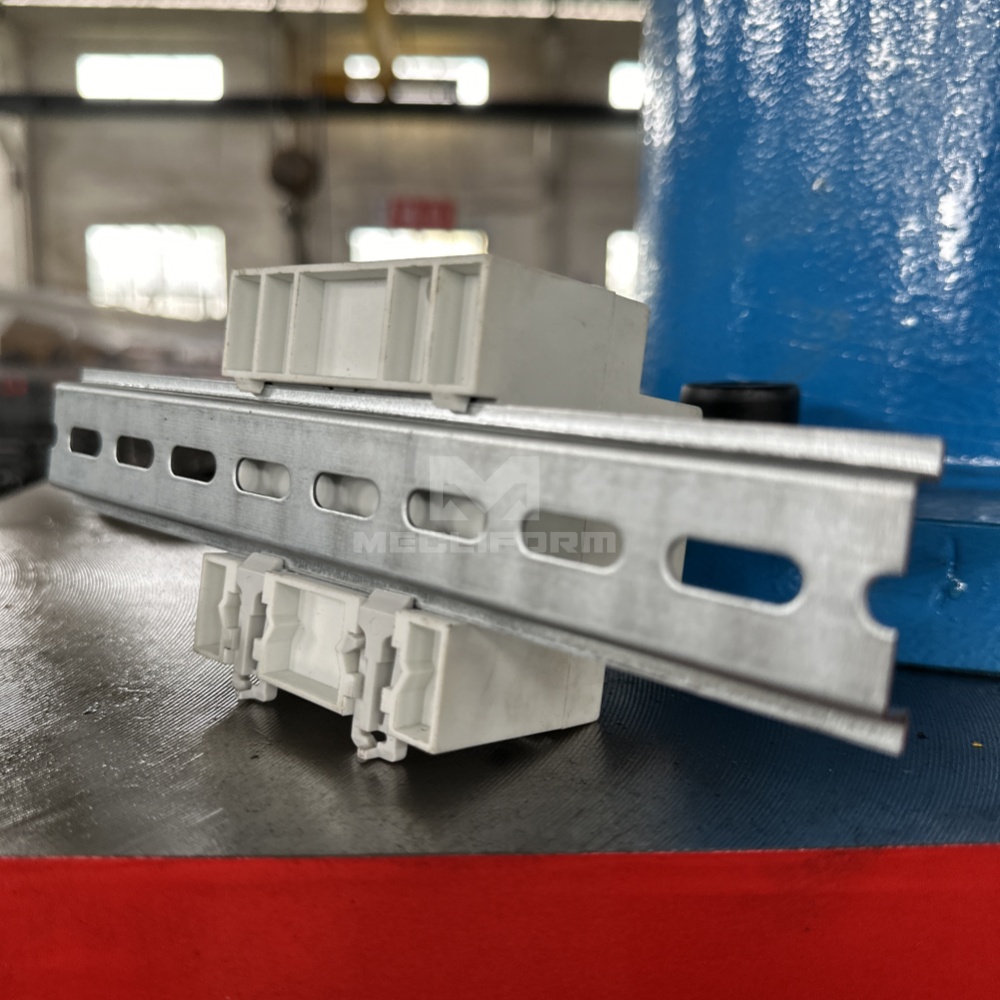

DIN rails are the long metal strips that form the core part of a global industry standard component rail-mounting system in equipment cabinet racks. DIN rails are designed for securely attaching electrical and industrial control products – such as circuit breakers, terminal blocks, power supplies, actuators, solenoids and so on – inside a typical equipment rack housing cabinet or frame.

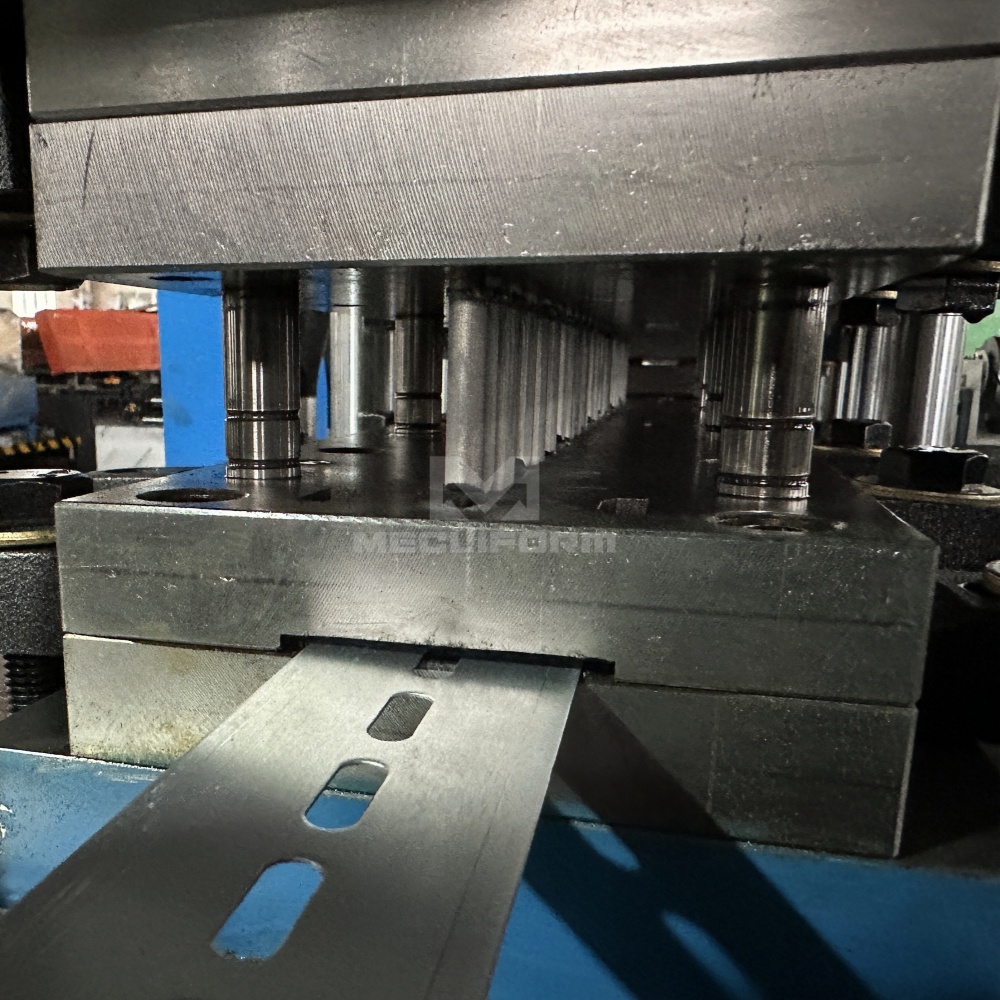

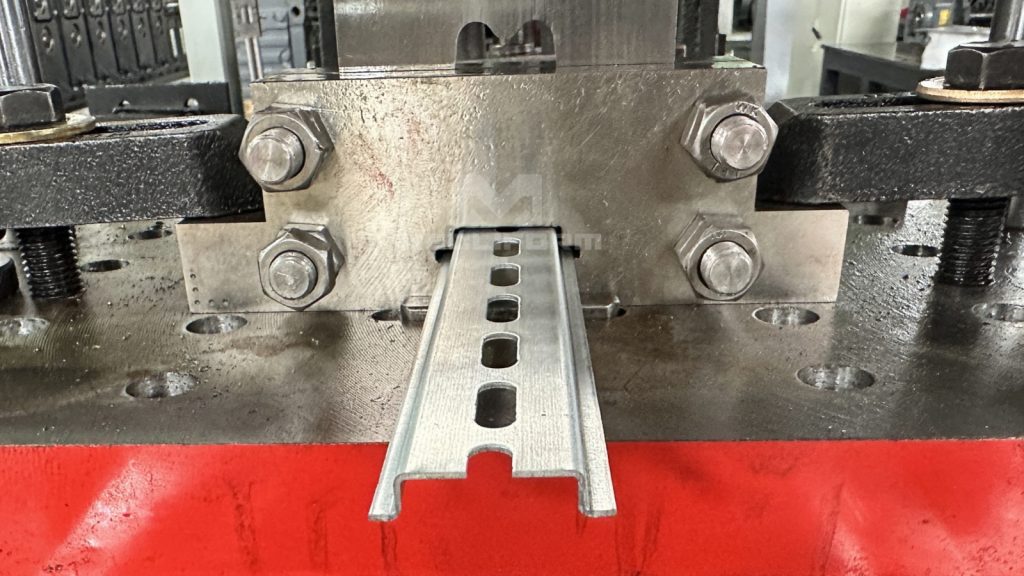

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

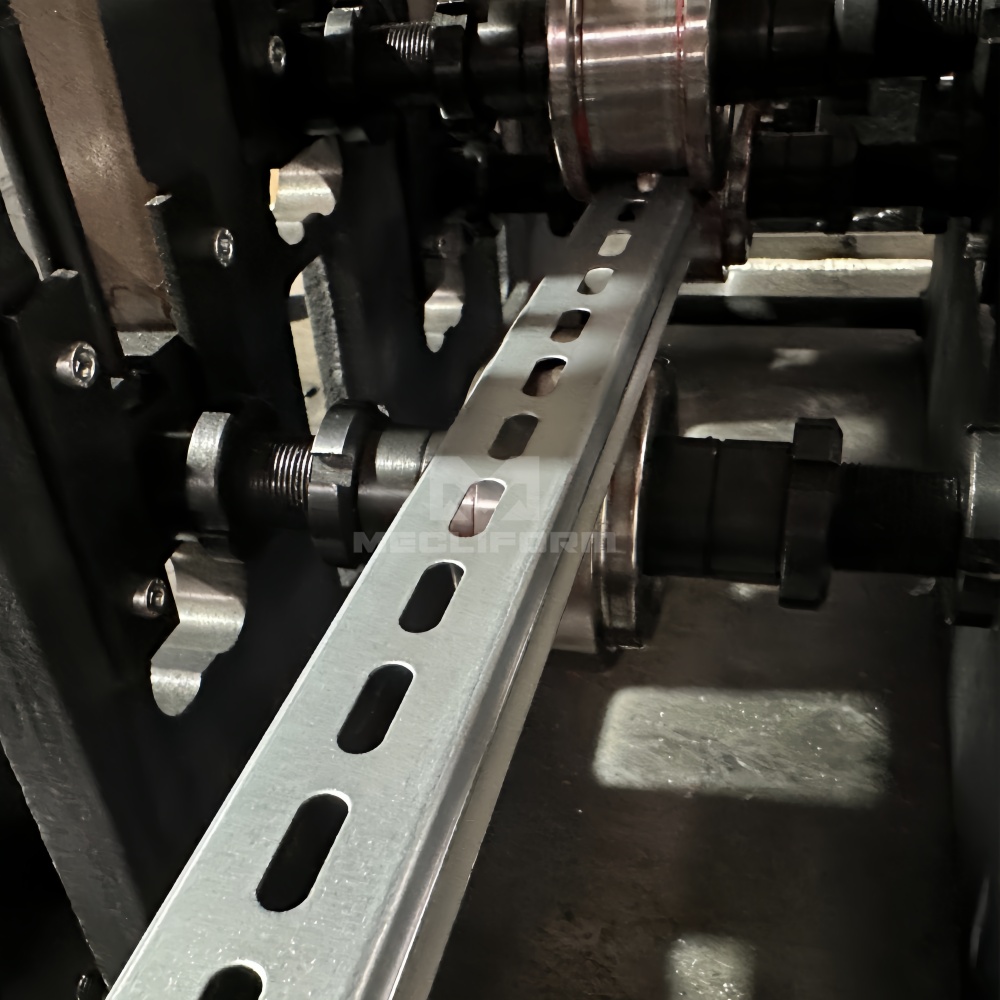

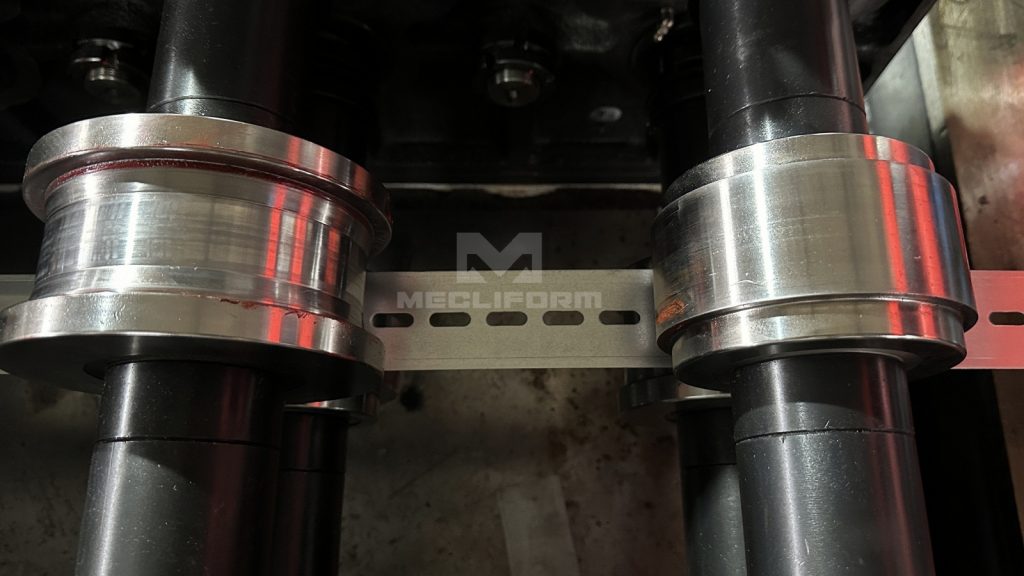

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.