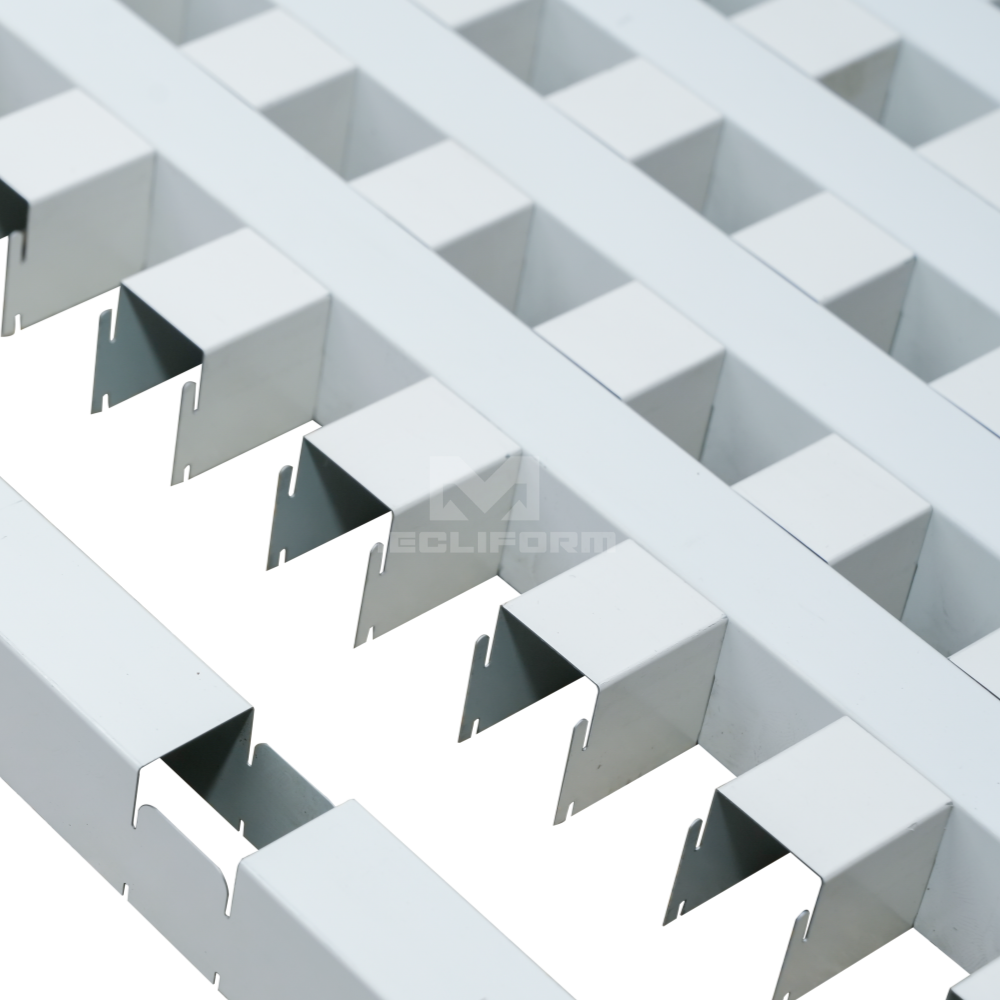

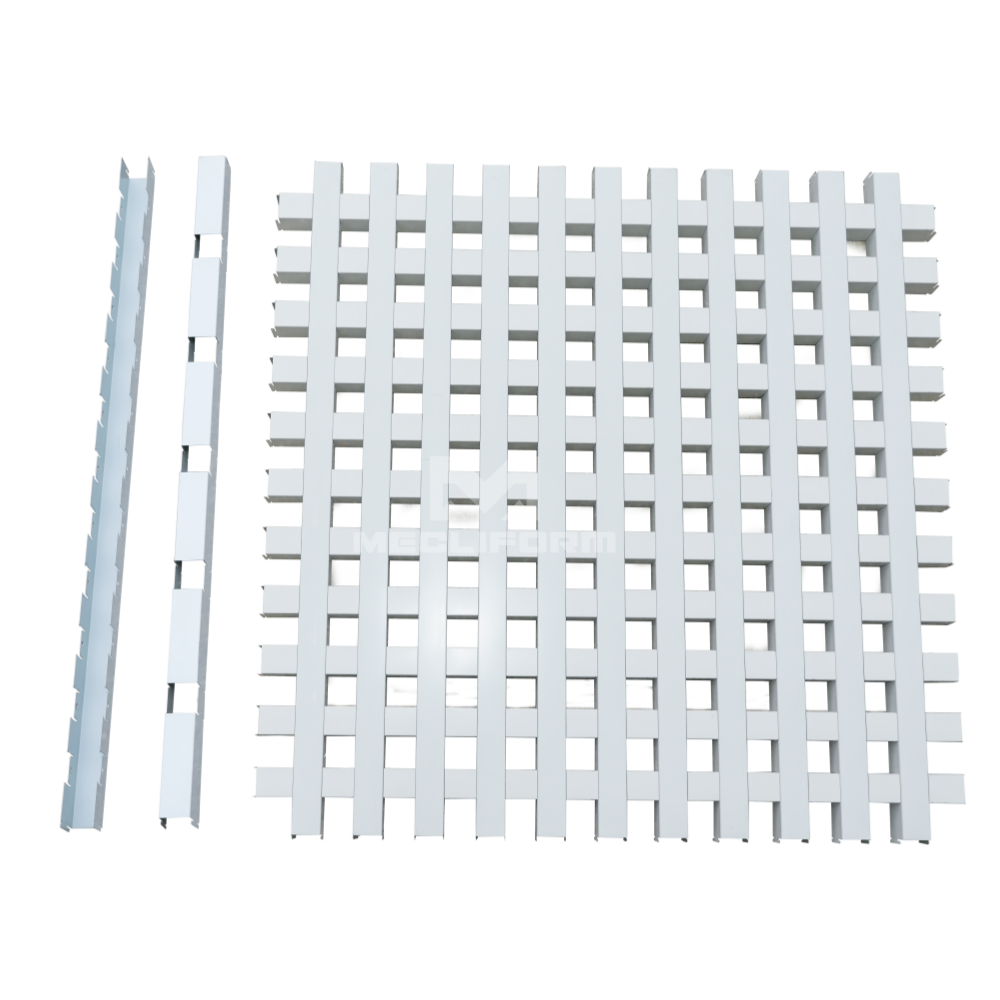

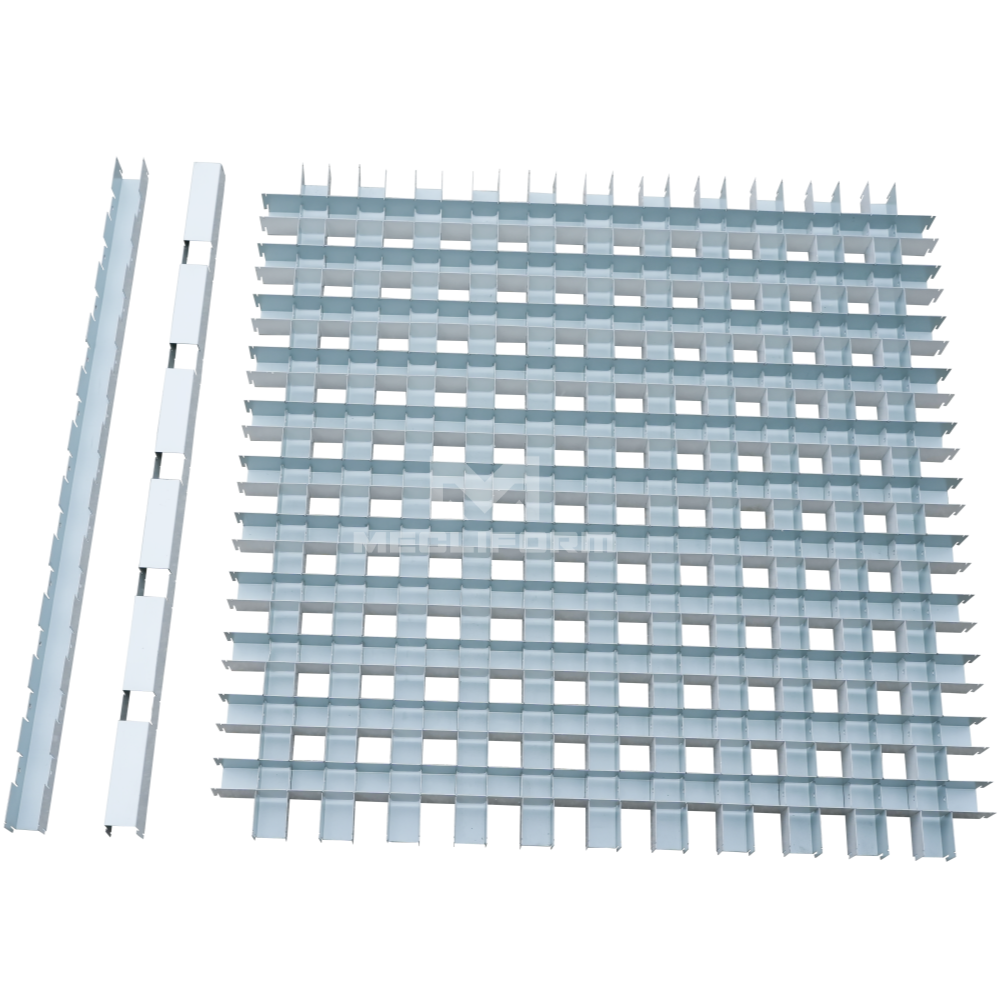

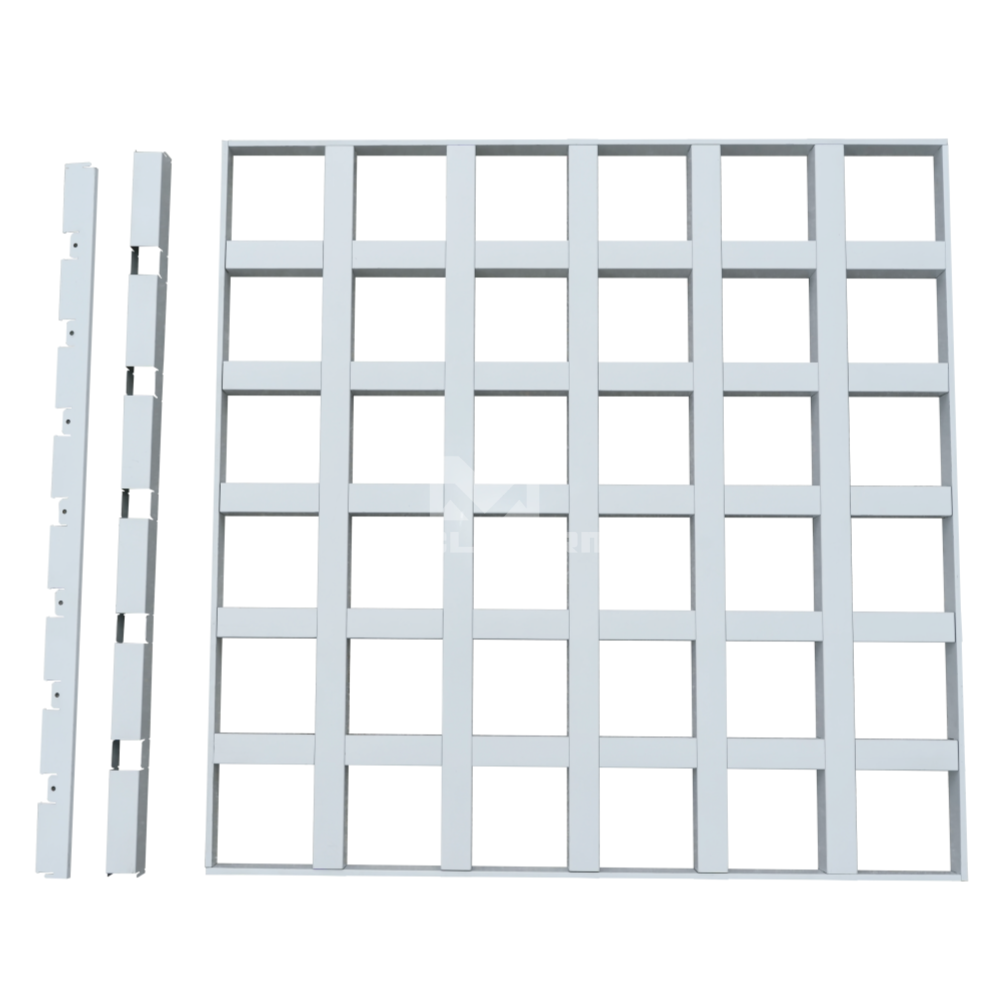

Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs. These machines are equipped with advanced features for pre-punching (one stroke one piece), cutting, forming, and finishing tiles with precision and efficiency.

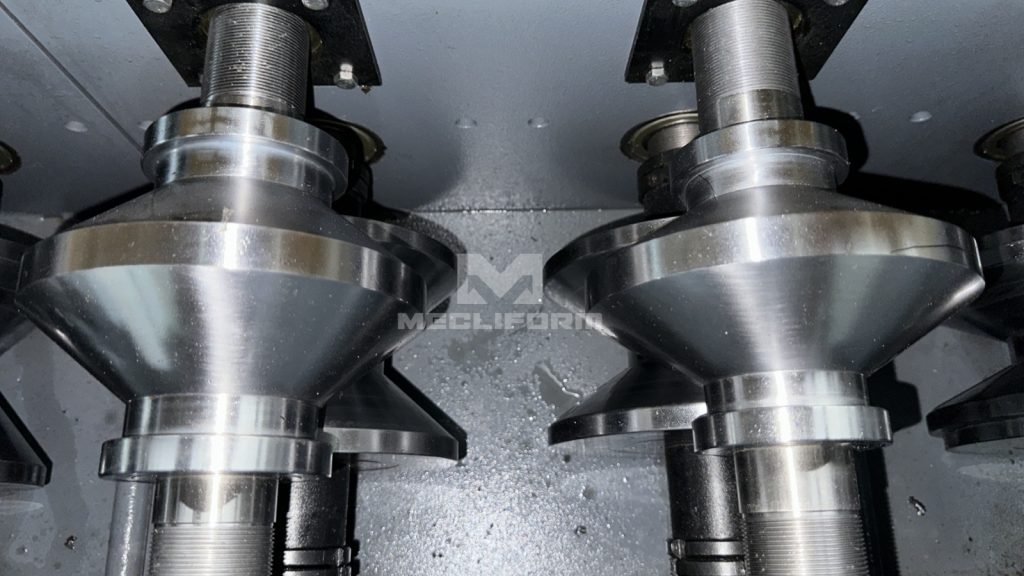

Punching & cutting unit is used to punch holes and pre-cut to length before roll forming. It typically consists of a series of metal tools that are working simultaneously. It’s fast speed design with one stroke one piece (L=600mm, step=50/100/…/300mm).

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a metal strip through a series of rollers that gradually bend and form the material into its desired shape. It’s available for width adjustable type.

L strip bending line is a standalone production line used to produce the L strip for GL24 product. It consists of a decoiler, leveler, hydraulic press (one stroke one piece), servo feeder, and bender.