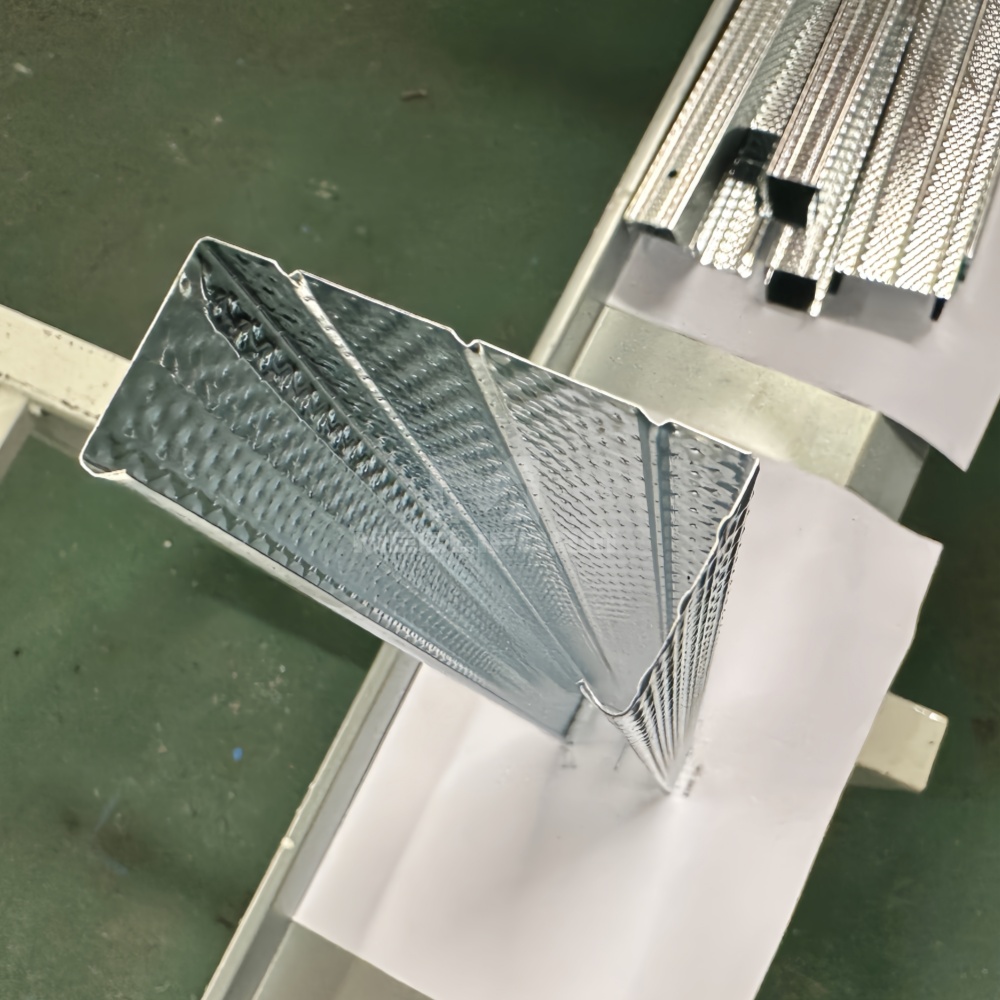

CU profile for suspended ceiling system is an architectural ceiling solution utilizing PPGI profiles as the primary structural framework. This system is suspended from the main ceiling structure using a network of metal grids, offering flexibility in design while maintaining structural integrity. PN6027 model equipment is two-strand type roll former, available to run synchronously, producing PP60x27 (C-Shaped) and PN27x28 profiles (U-Shaped) at the same time.

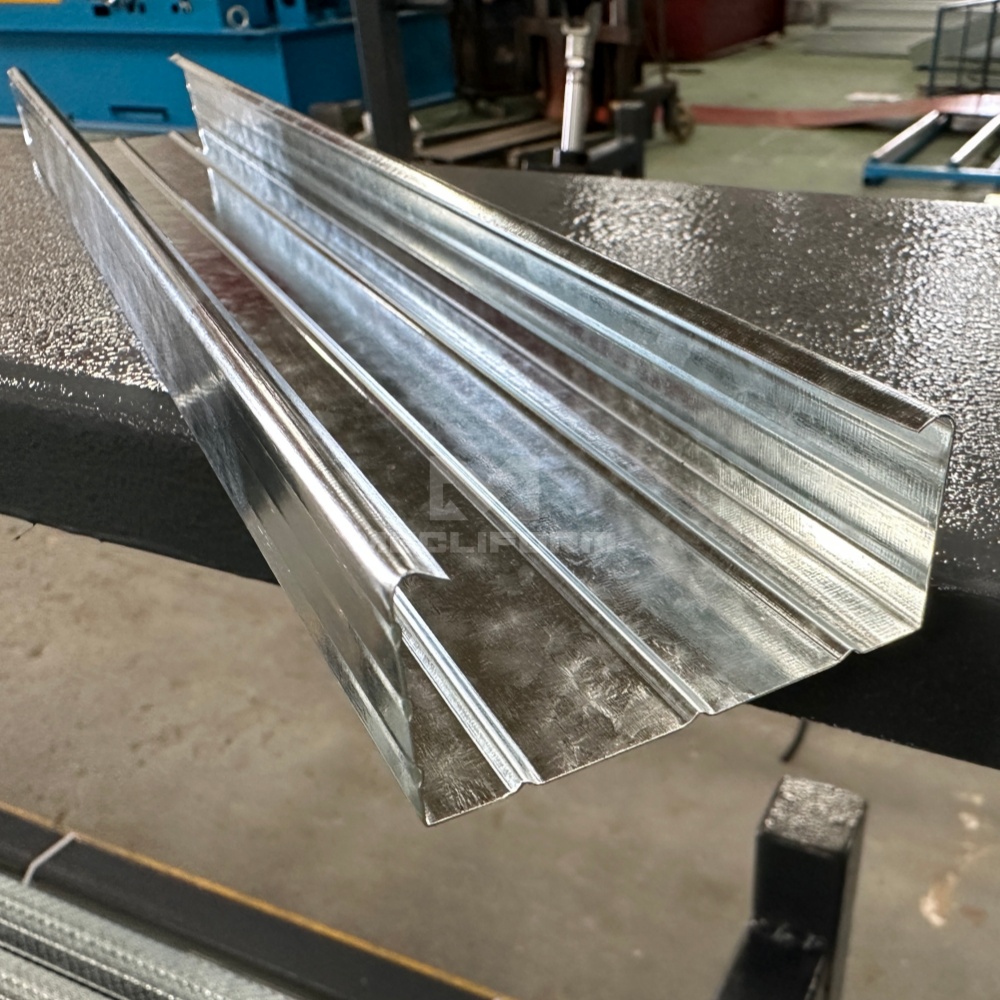

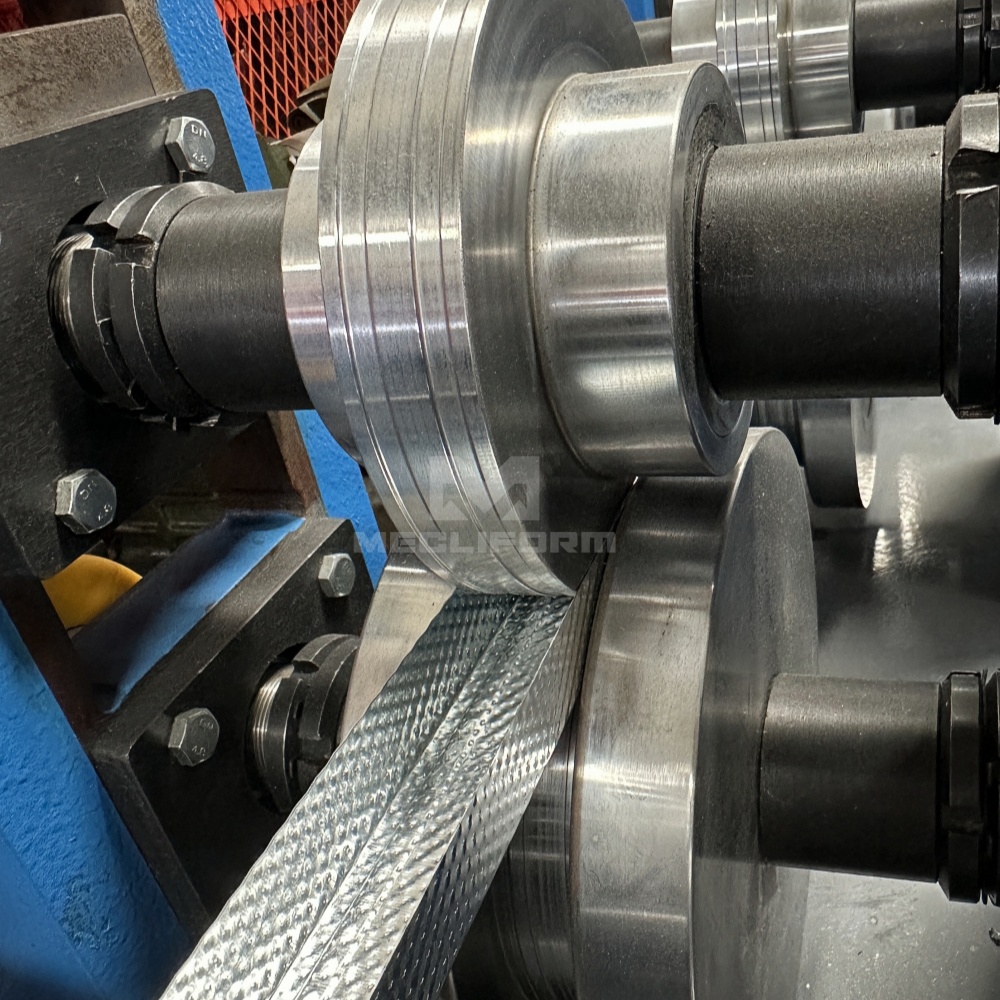

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a metal strip through a series of rollers that gradually bend and form the material into its desired shape. It’s available for width auto adjustment type.

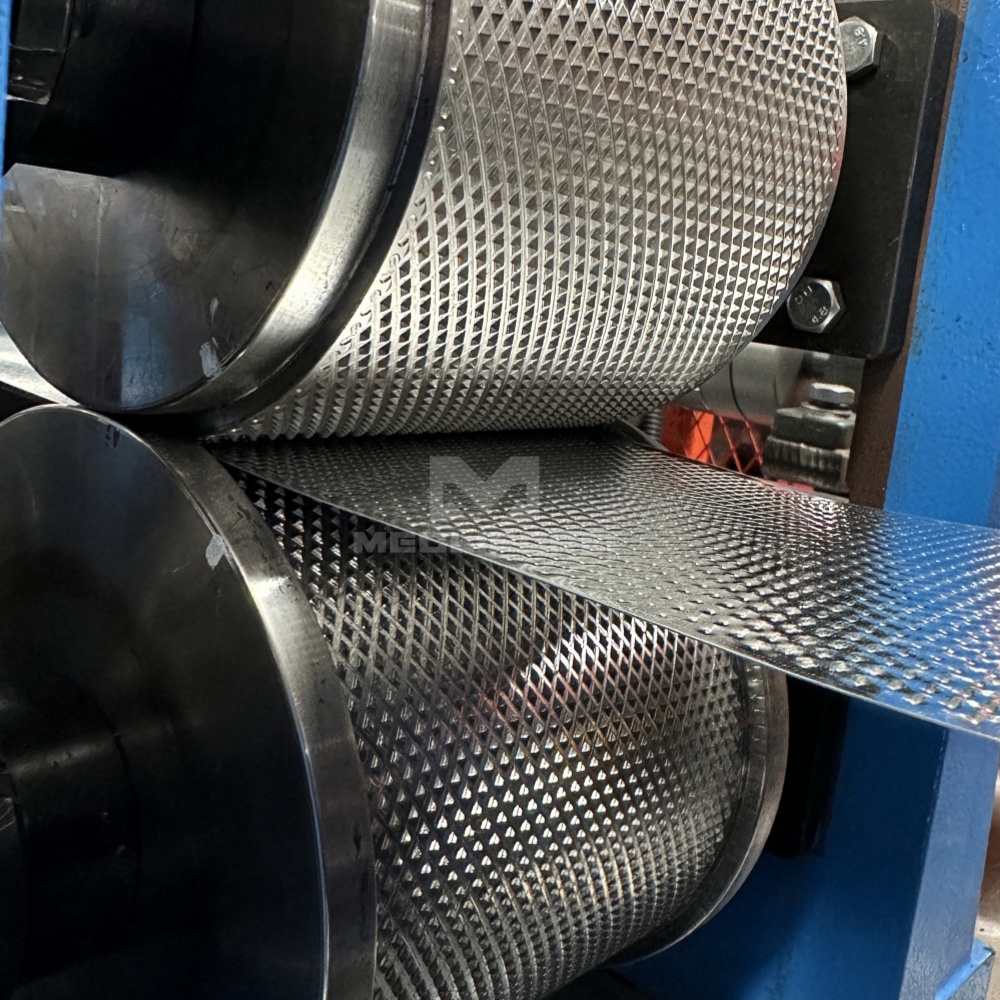

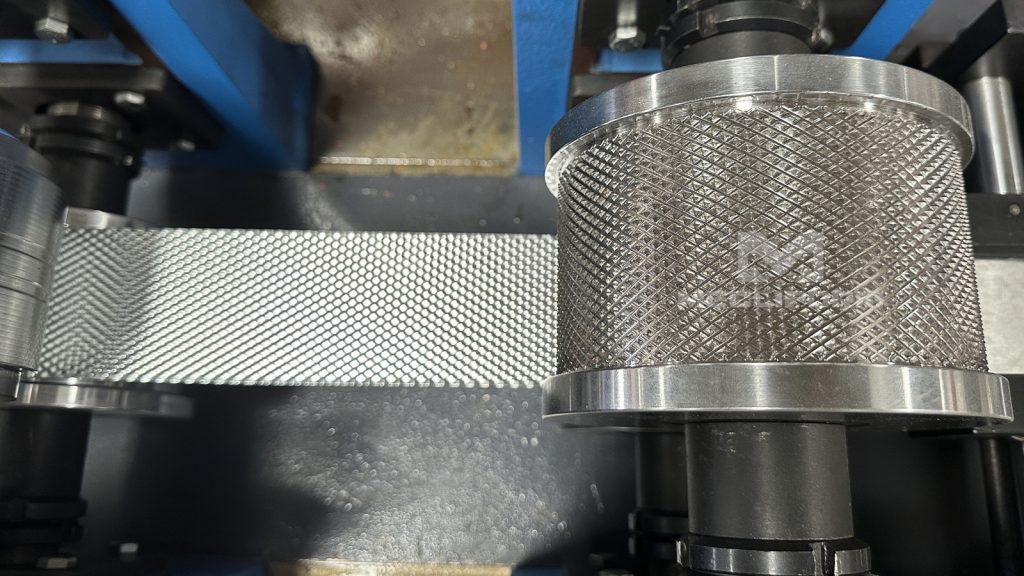

Corrugating roller is a precision-engineered cylindrical roller (upper and lower) used in manufacturing of corrugated CU stud. it features a specially designed grooved or fluted surface that shapes flat metal surface into a wave-like (corrugated) pattern when pressed under pressure.

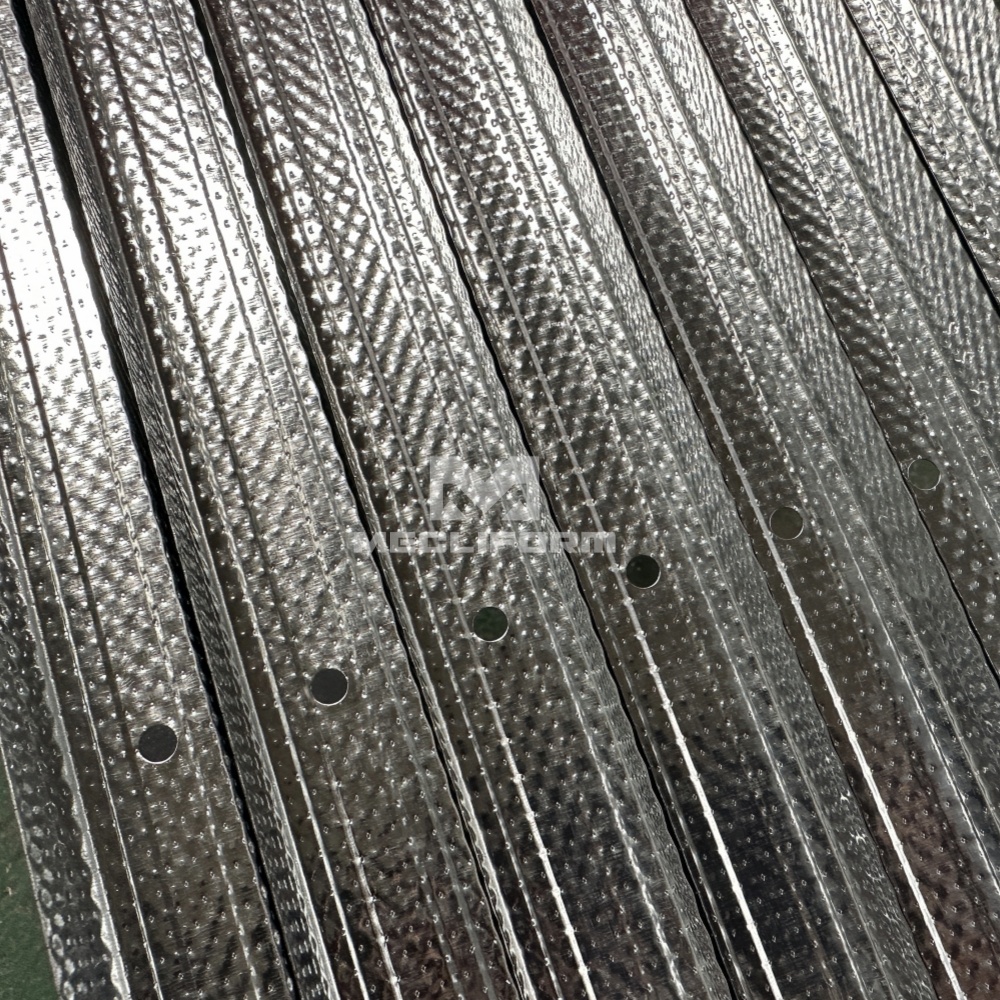

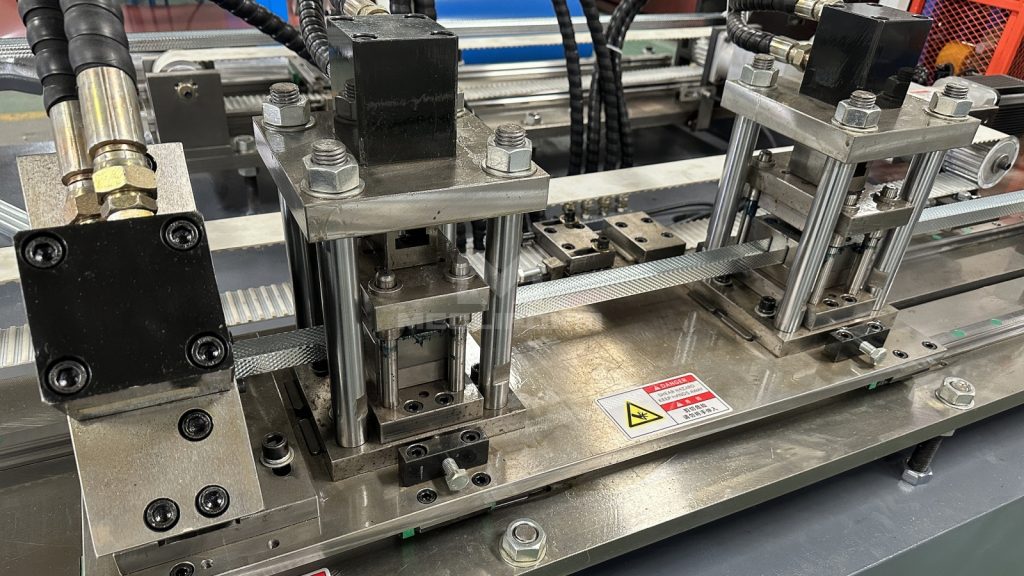

Post punching unit is used to punch holes after roll forming. It typically consists of a metal tool (punching & logo stamping) that is propelled with force through the material to create the desired hole.

Hydraulic cutting unit is used to provide smooth and clean cuts. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.