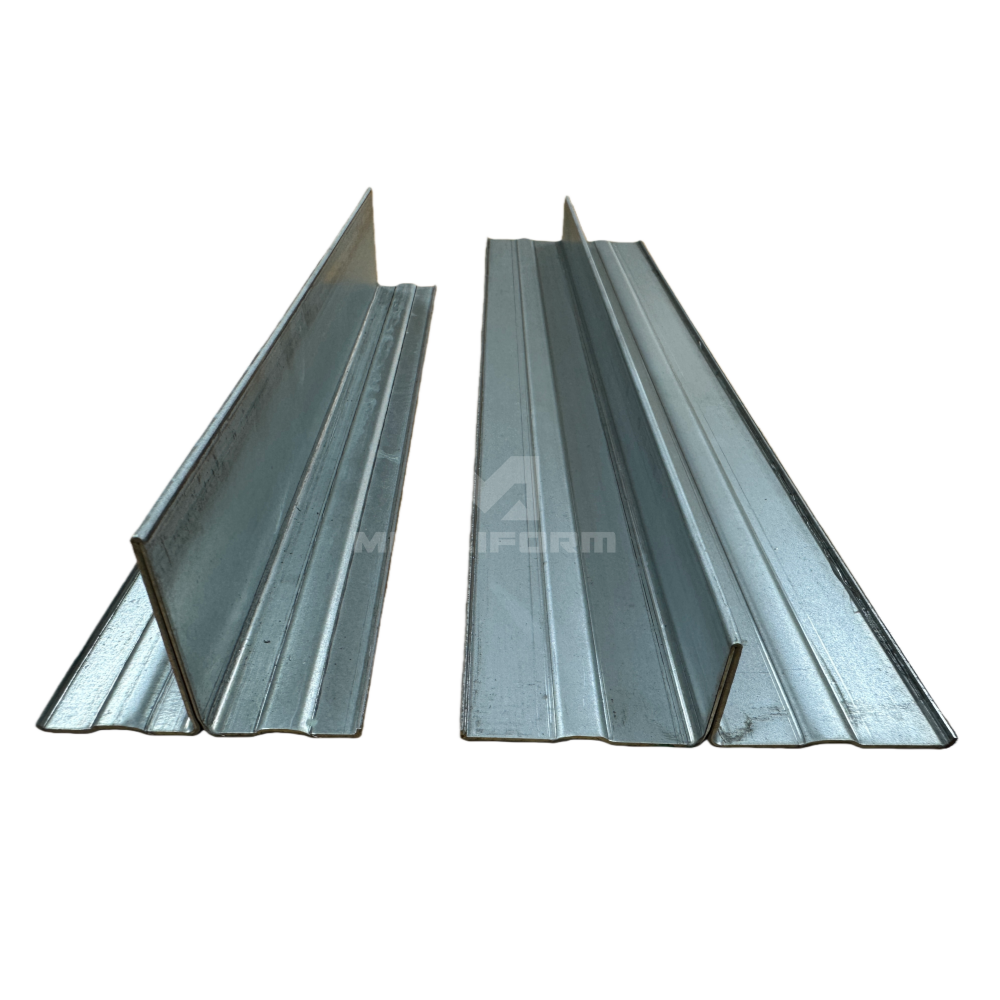

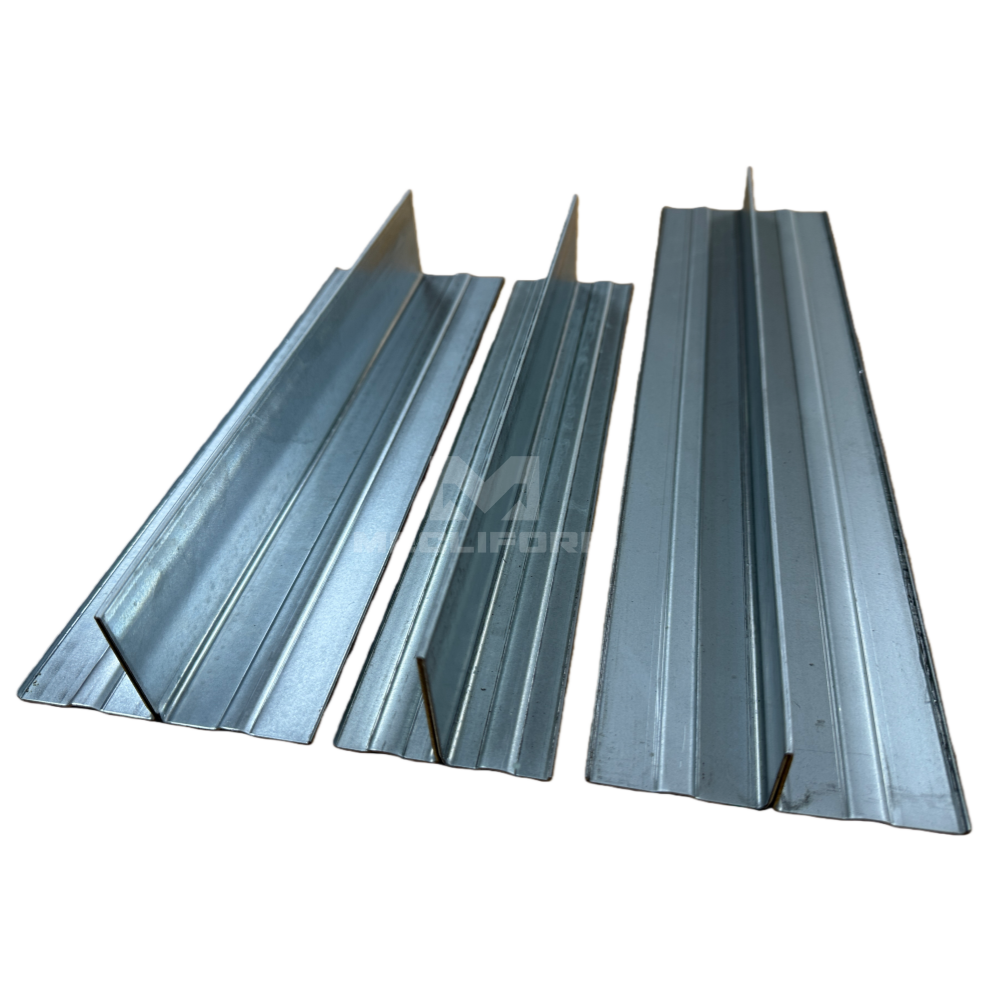

T profile roll forming machine (single strand or two strands), consists of decoiler, roll former and cutting unit (without waste). It achieves high efficiency.

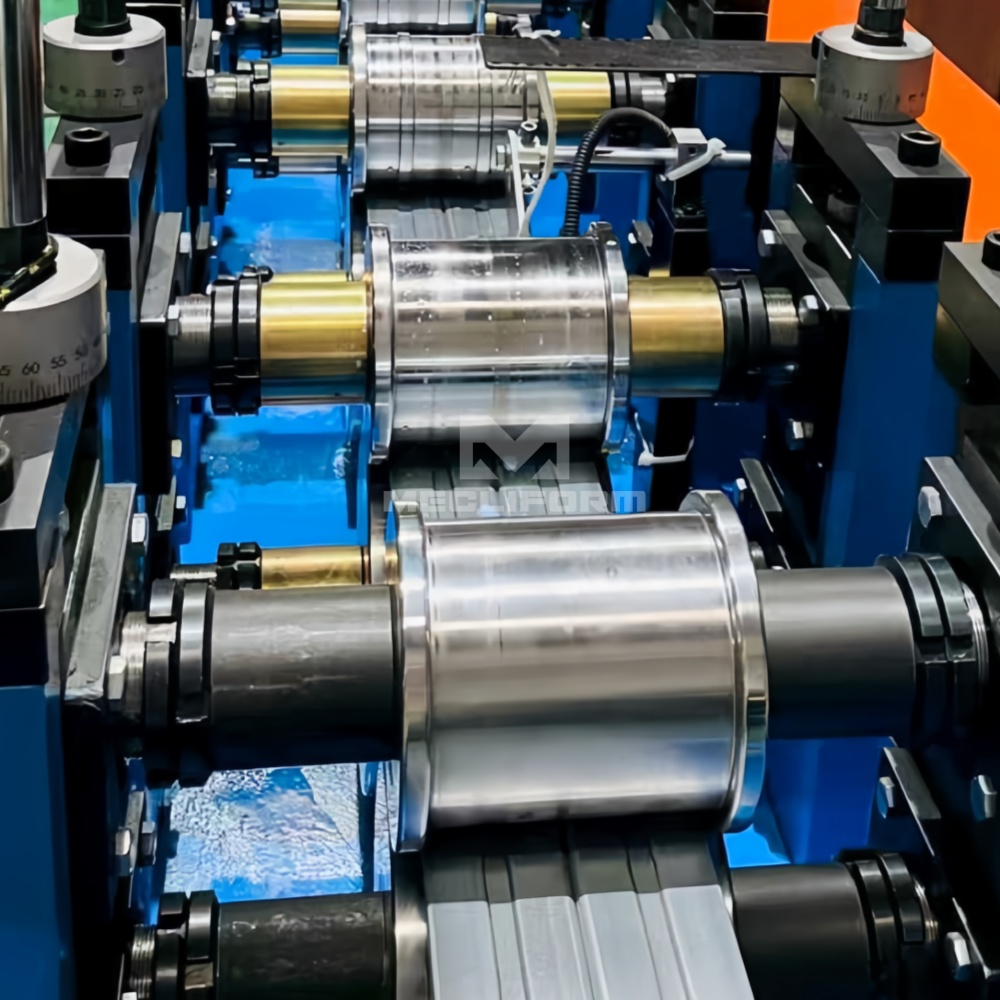

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

Hydraulic cutting unit is used to provide smooth and clean cuts. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.