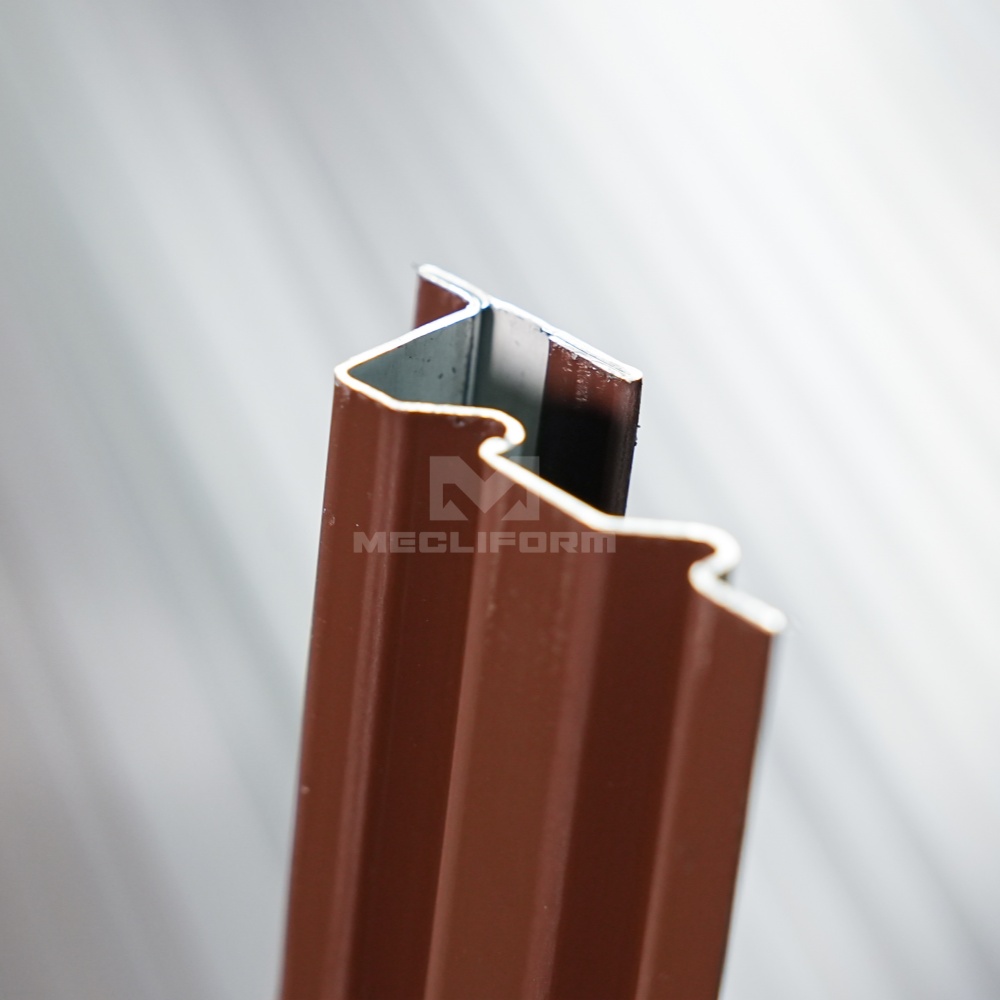

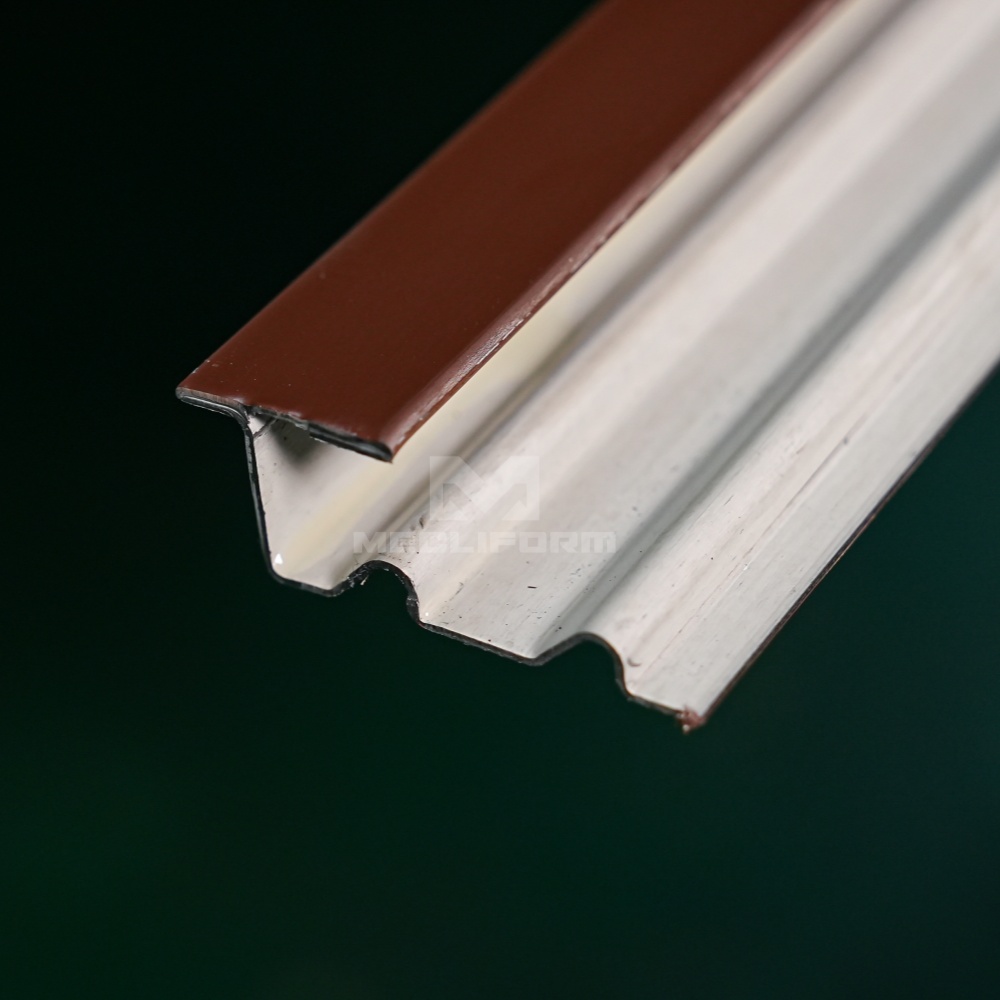

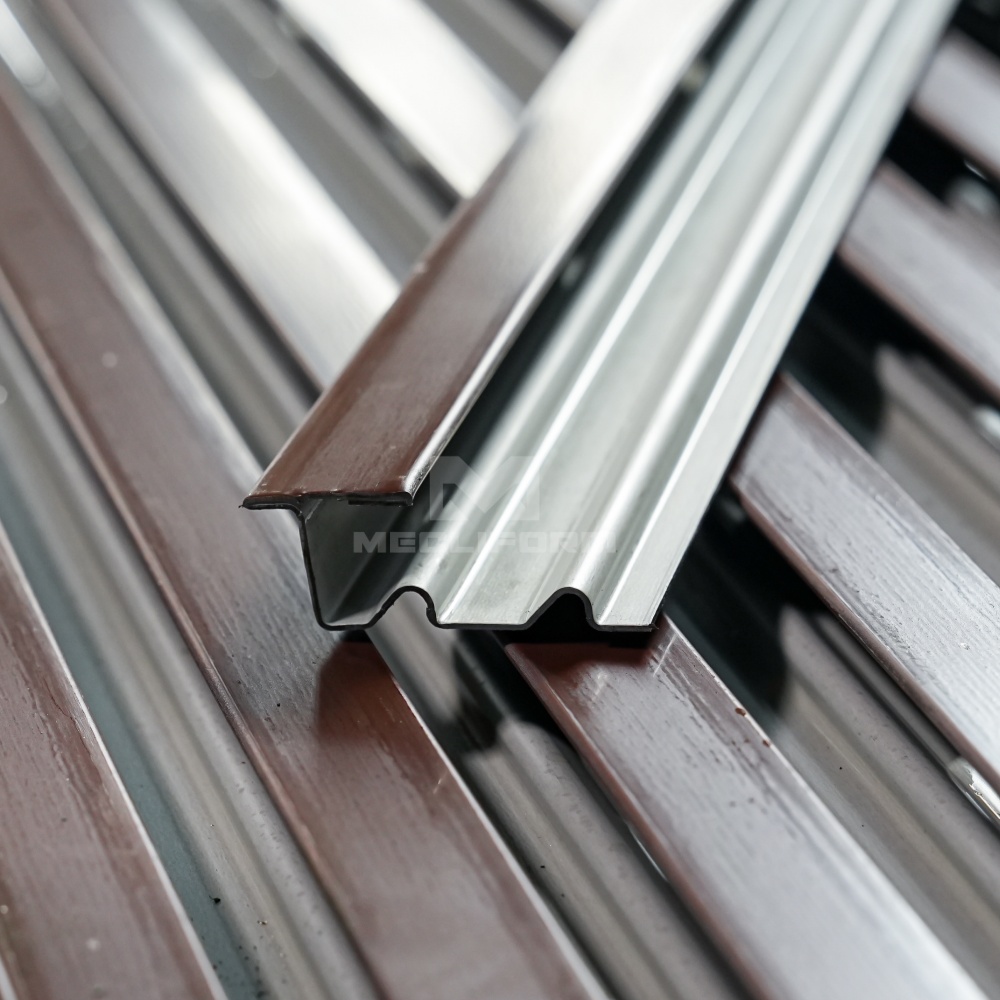

Side tile mounting profile is a narrow metal strip that is used to securely attach tiles to a vertical surface, such as a wall or staircase riser. The profile typically features a groove or channel that allows the tiles to sit flush against the surface, creating a clean and seamless look. Side tile mounting profiles come in various lengths and finishes to match different tile styles and design preferences. They are often used in conjunction with corner profiles to ensure a professional and finished installation of tiles in residential and commercial spaces.

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

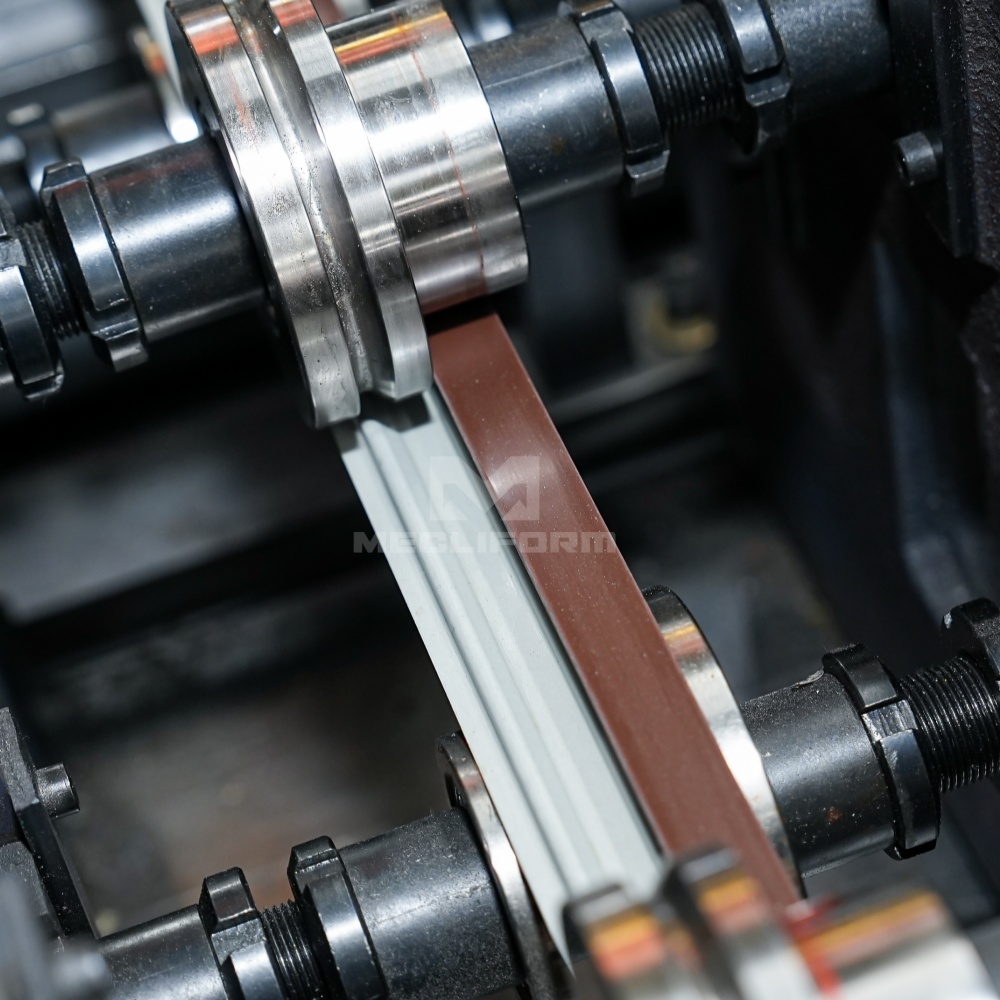

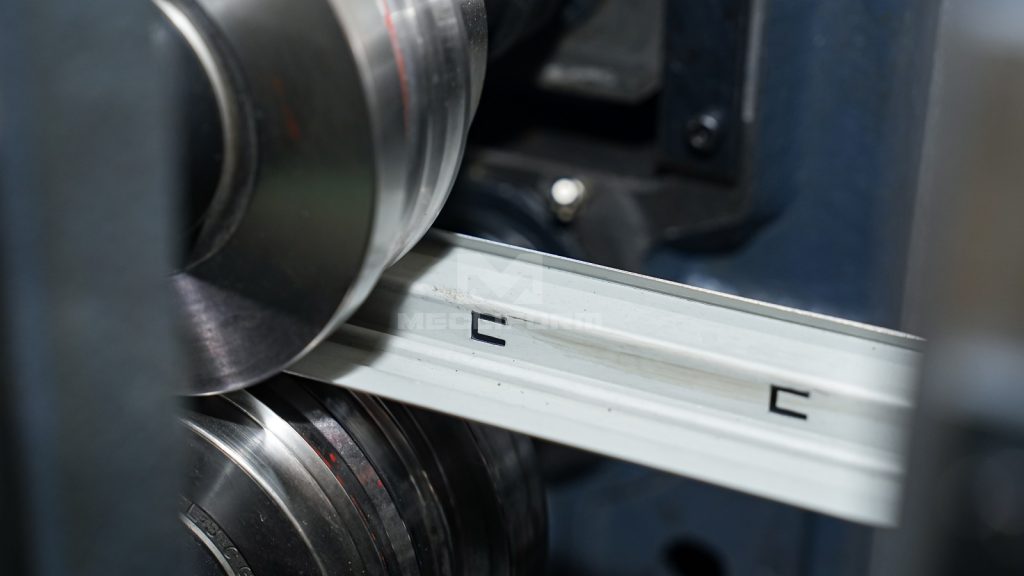

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type.

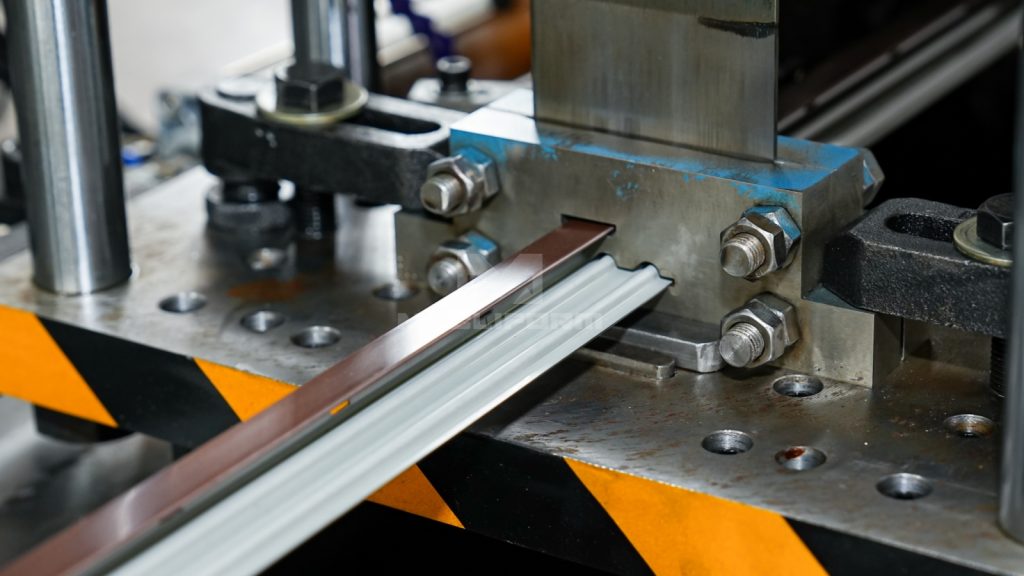

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.