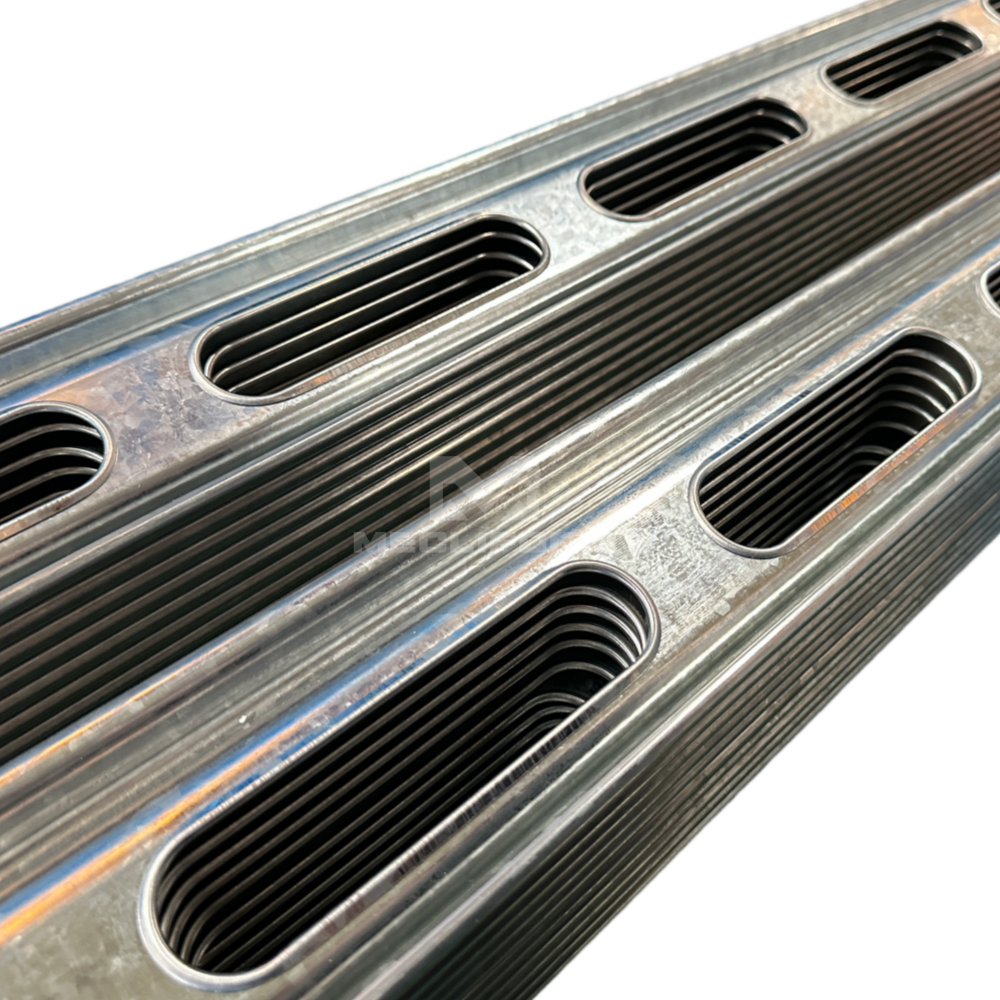

Rolling Shutter Door Profile Auto Production Line is a fully automated manufacturing system designed for high-efficiency, precision production of rolling shutter door profiles (slats). This advanced production line integrates roll former, punching & folding unit, hydraulic cutting unit, and auto control systems to ensure consistent output with minimal human intervention.

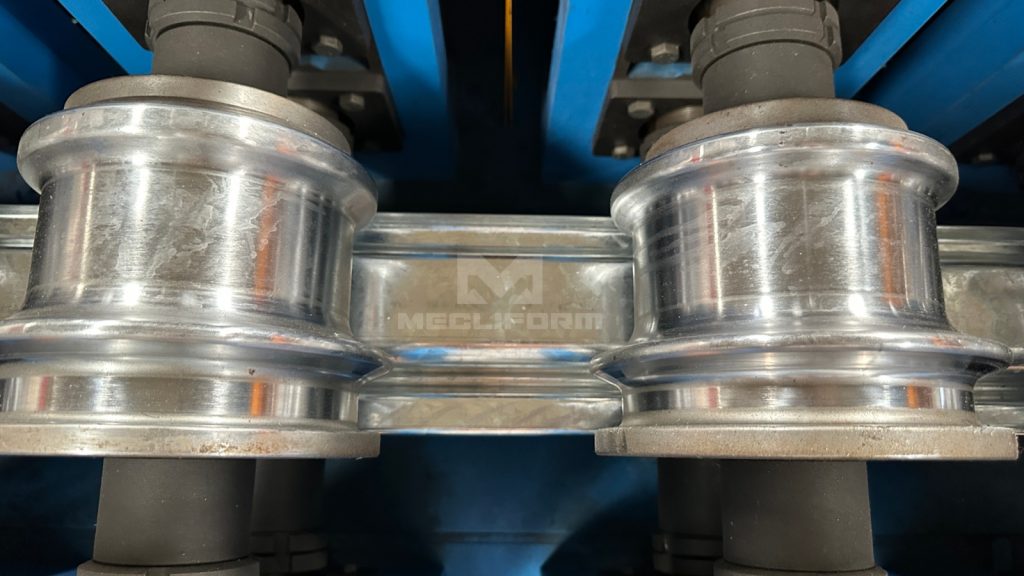

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

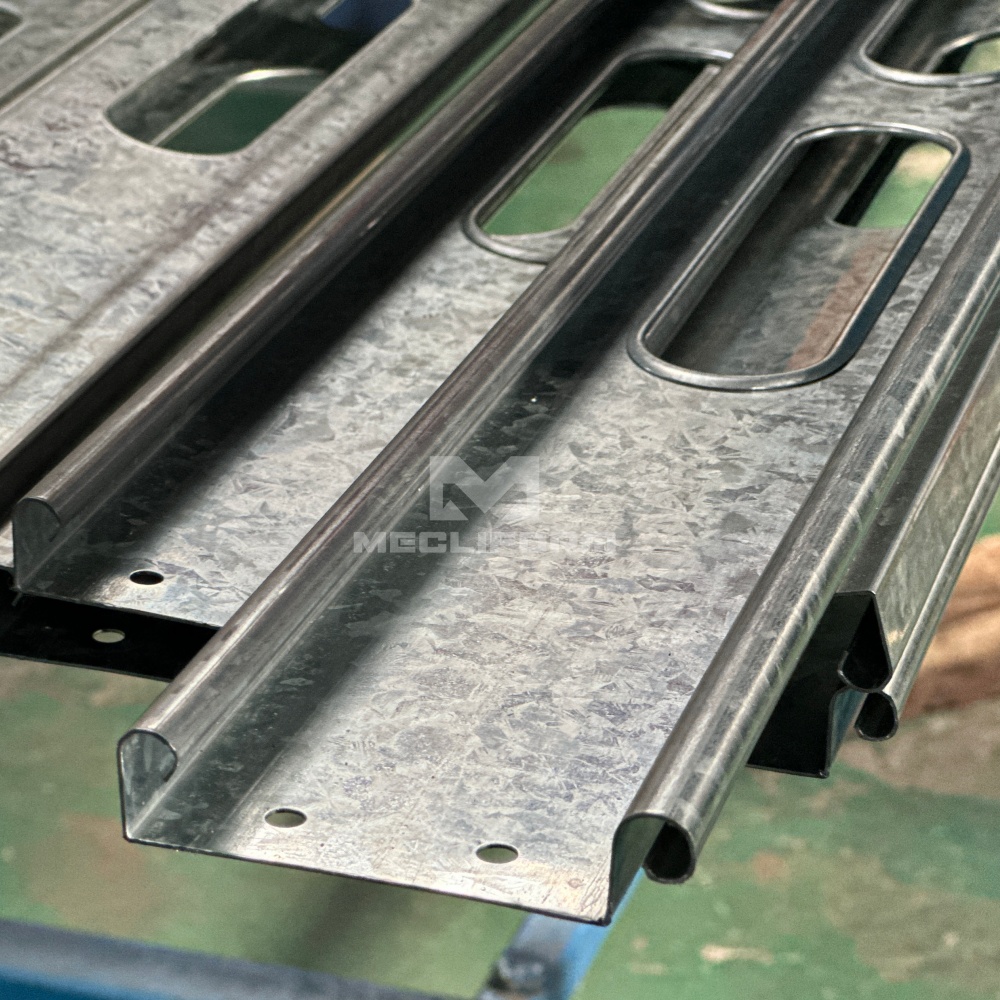

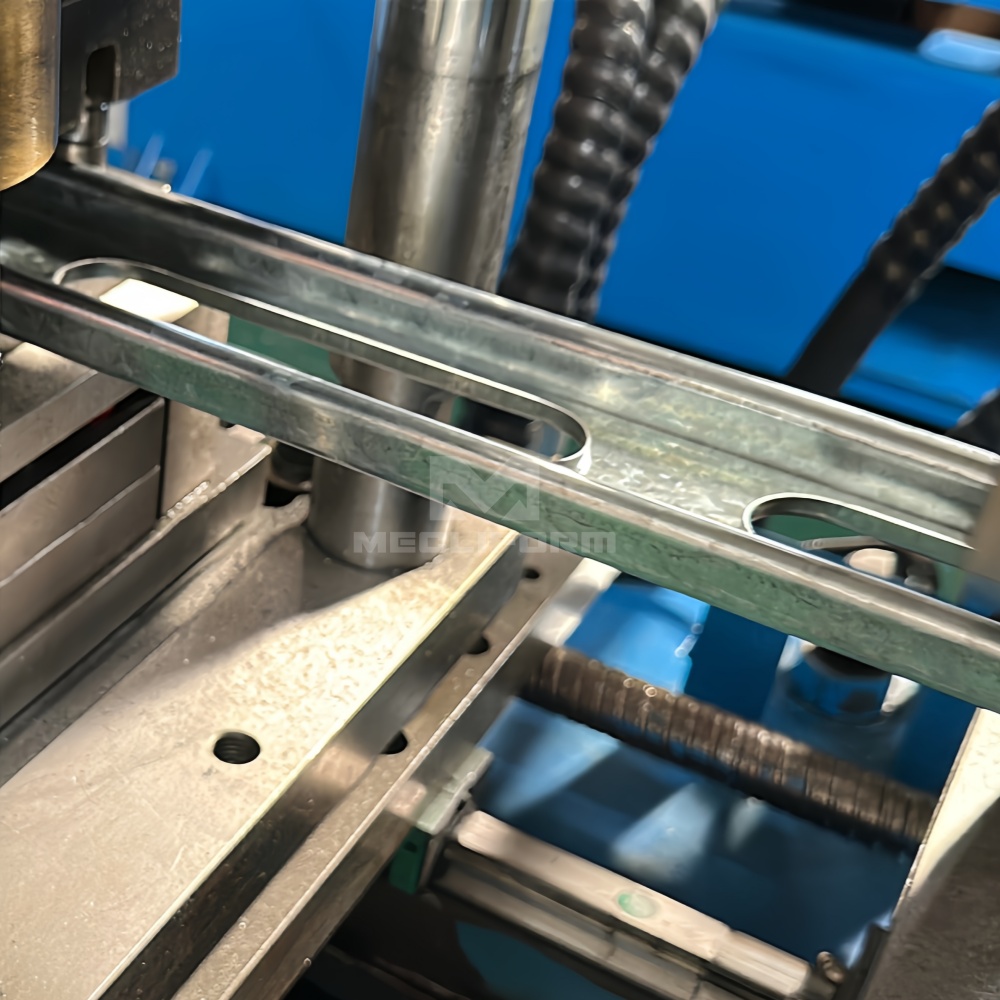

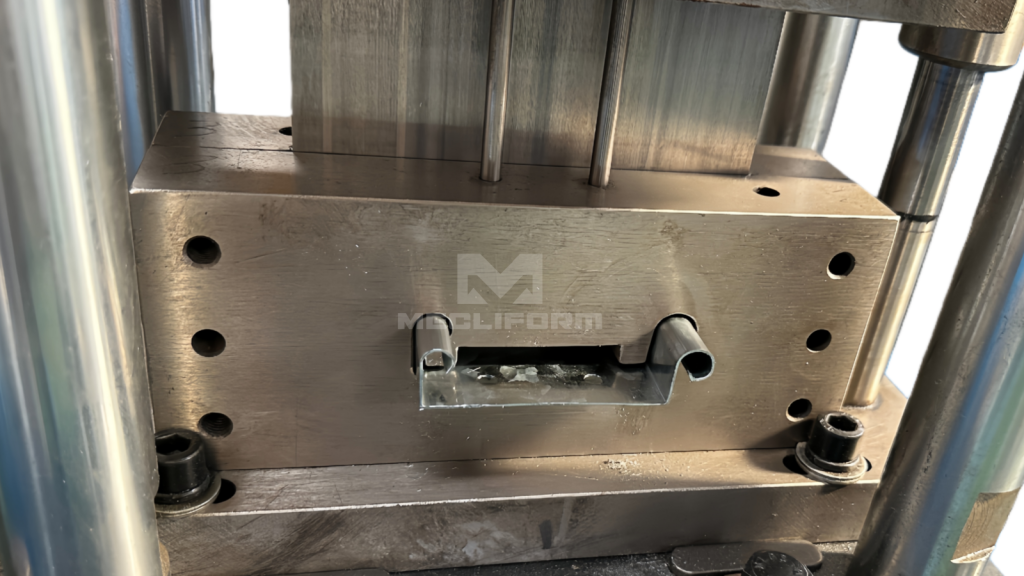

Punching & folding unit is used to punch holes, meanwhile folding and pressing after roll forming. It typically consists of metal tools that are propelled with force through the slats to create the desired hole or shape.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.