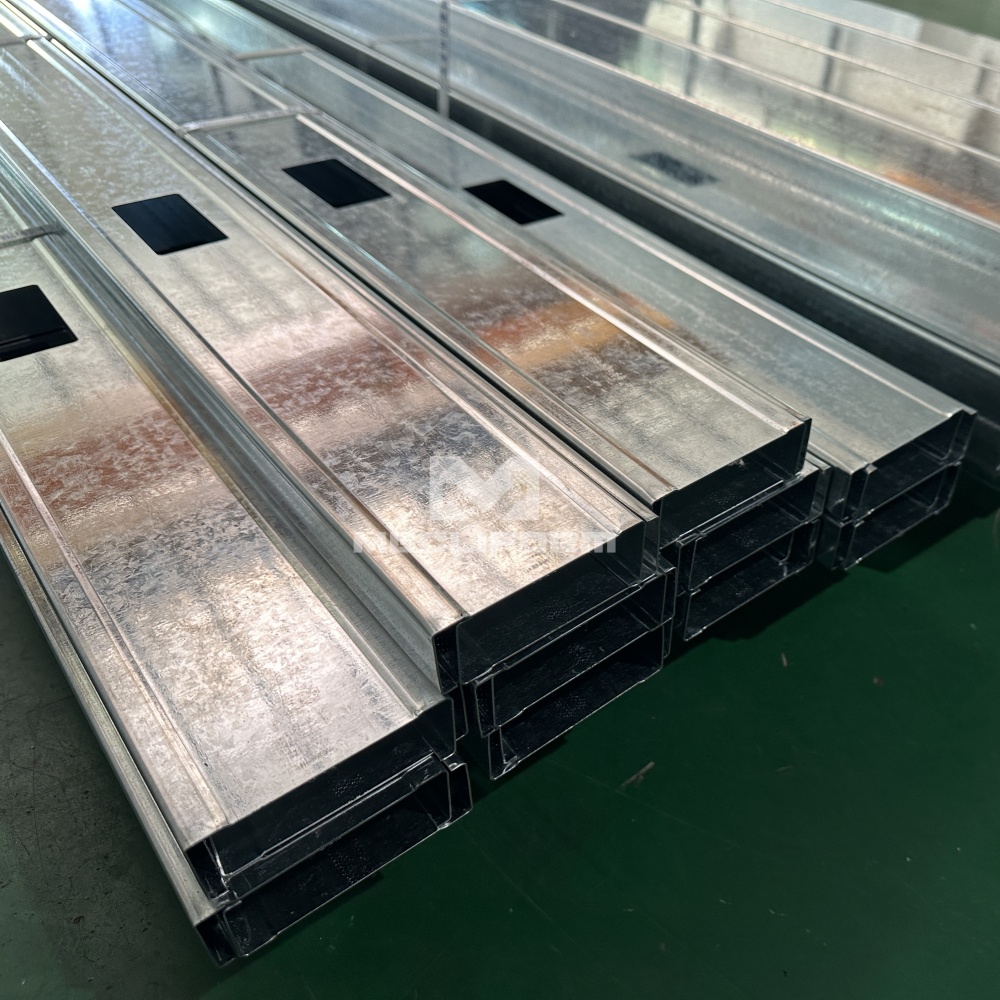

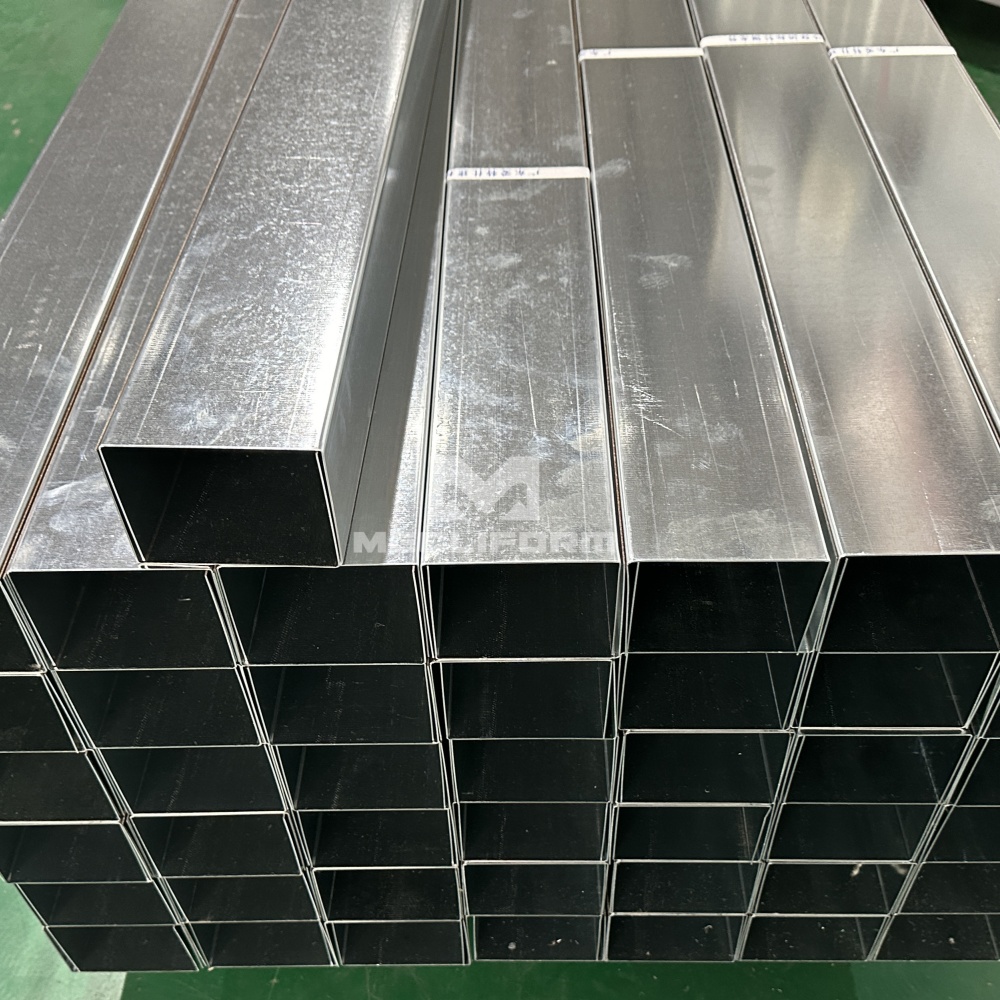

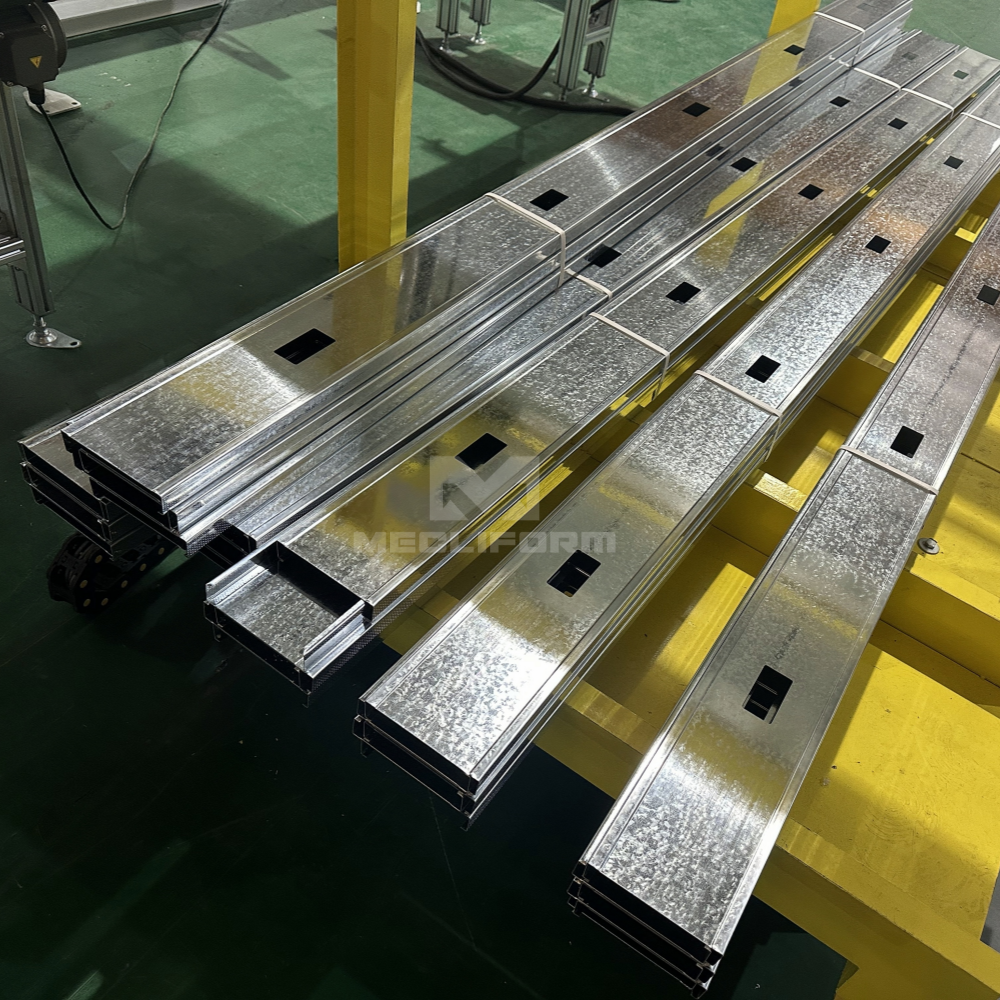

Stud and track are essential components used in the construction of interior framing systems. The stud is a vertical structural member that provides support for walls, ceilings, and floors, while the track is a horizontal component that the studs are attached to. Together, they create a strong and stable framework that forms the skeleton of a building. Studs are typically made of wood, metal, or composite materials and come in various sizes to accommodate different wall heights and load-bearing requirements. They are placed at regular intervals along the length of the wall and are fastened to the track using screws or nails. Tracks are usually made of metal and are attached to the floor and ceiling to create a level base for the studs. They also serve as a guide for the placement of the studs and help to maintain the structural integrity of the framing system.

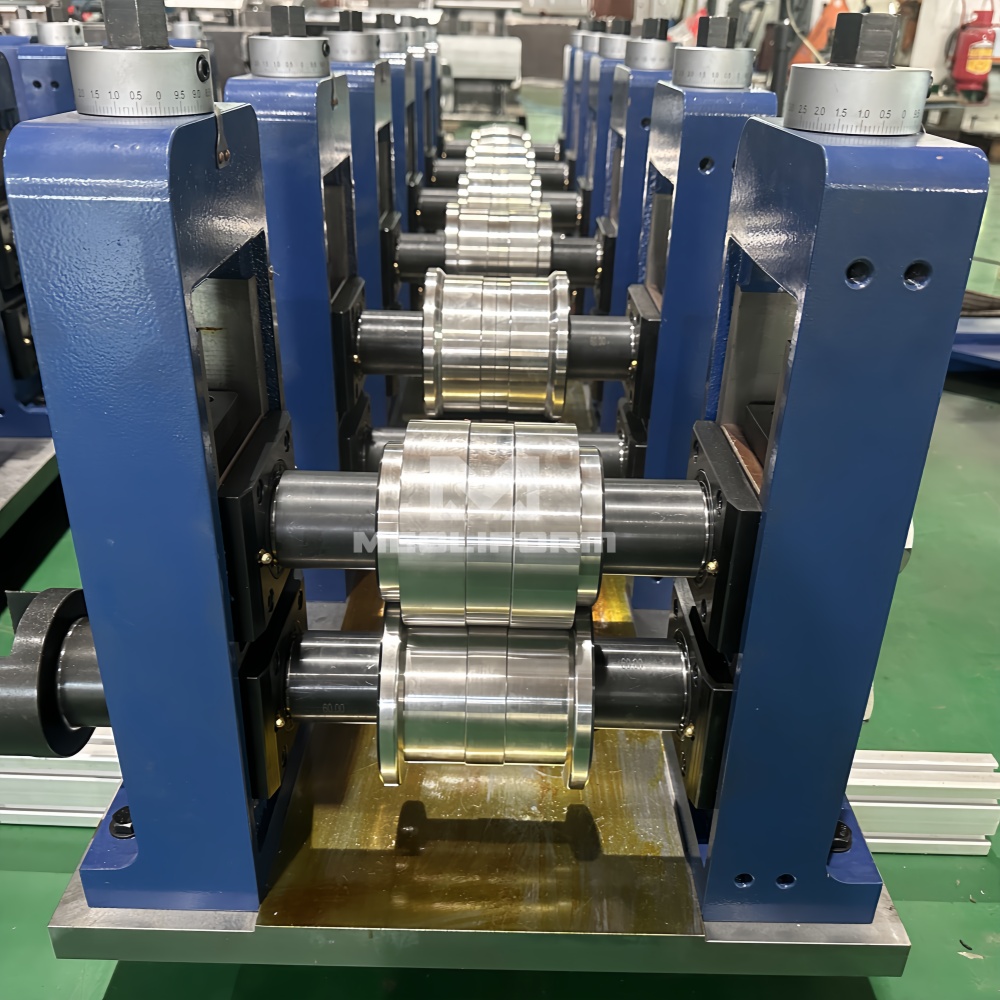

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. If necessary, it can be designed with a replaceable cassette for quick-change type.

Hydraulic post punching unit is a high-performance, hydraulically driven punching unit after roll forming and before cutting to length designed for precision hole punching, notching, and forming operations in metal fabrication.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.