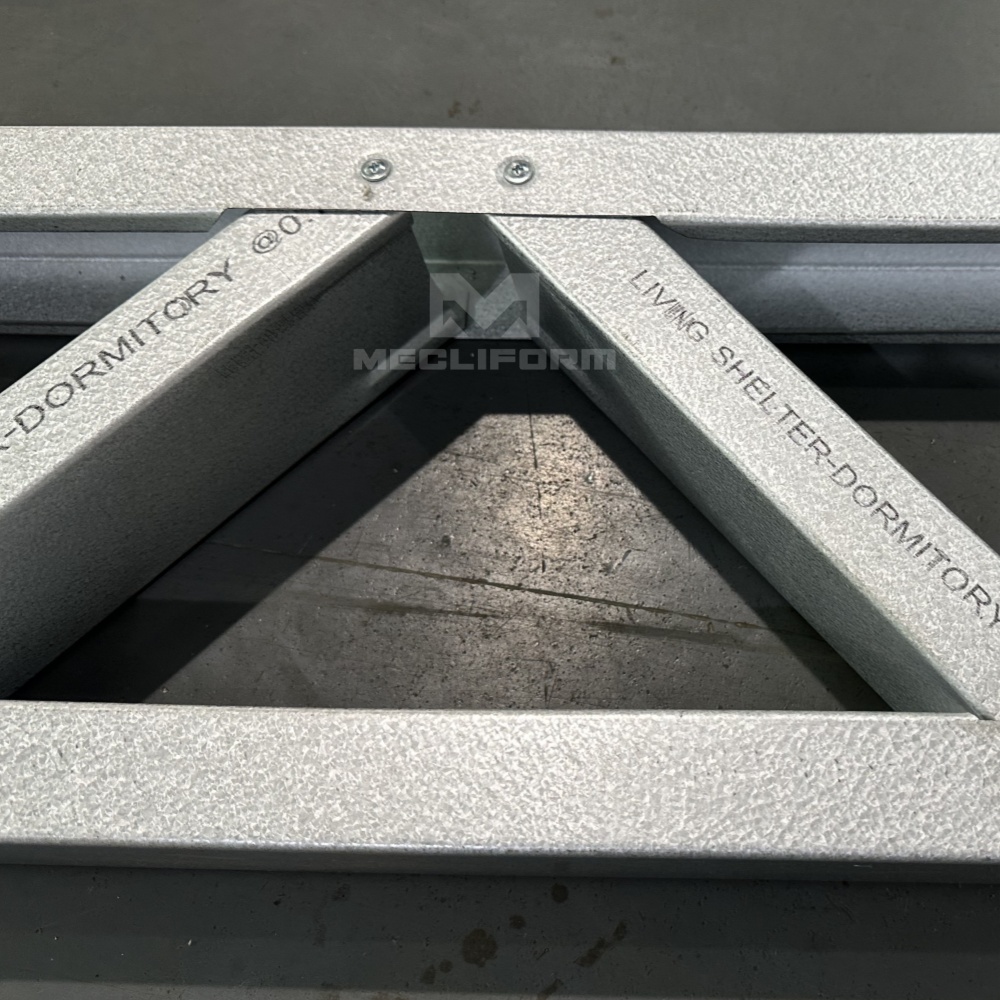

Our storage and logistics machinery includes roll formers designed to produce shelving, racking, and other storage solutions for warehouses, distribution centers, and manufacturing facilities. These machines are built to withstand heavy use and deliver precise, consistent results. These machines are versatile and can be easily adjusted to create different profiles and sizes to meet specific project requirements.

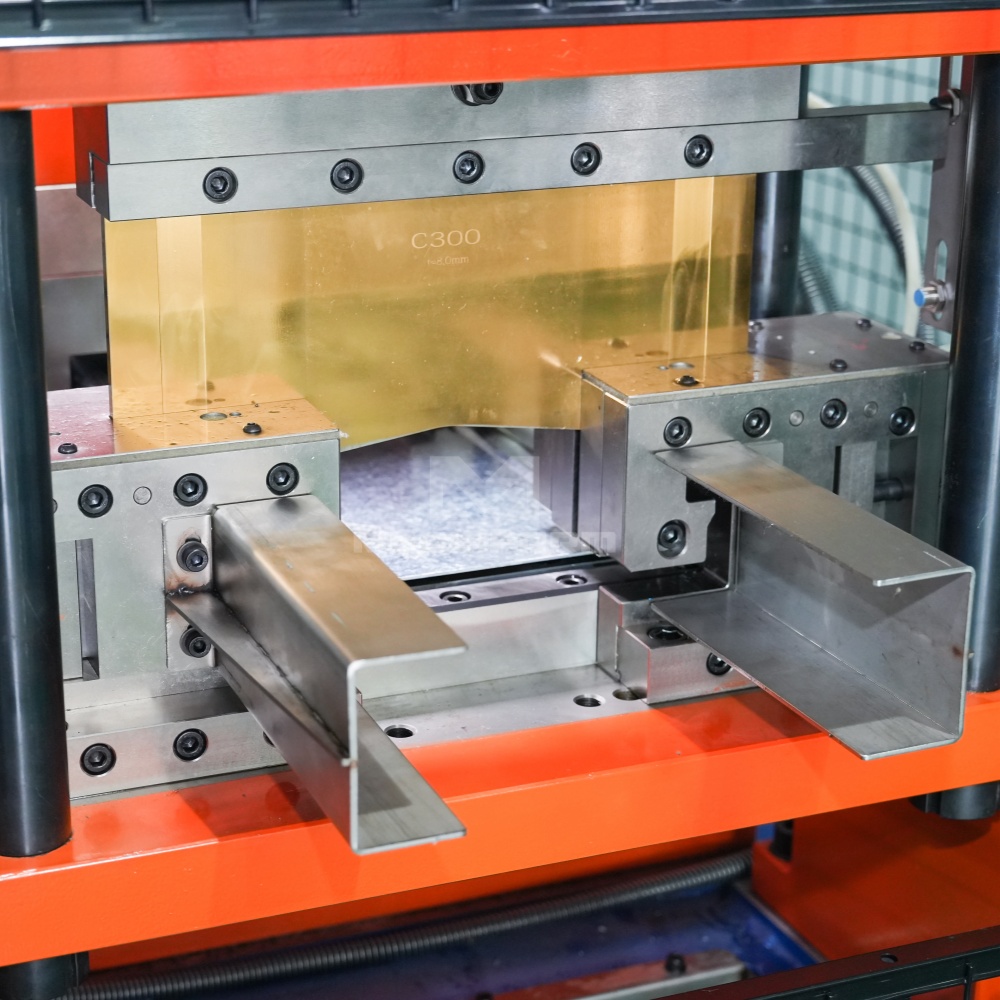

Punching unit is used to punch holes before roll forming. It typically consists of metal tools that are propelled with force through the material to create the desired holes or notches.

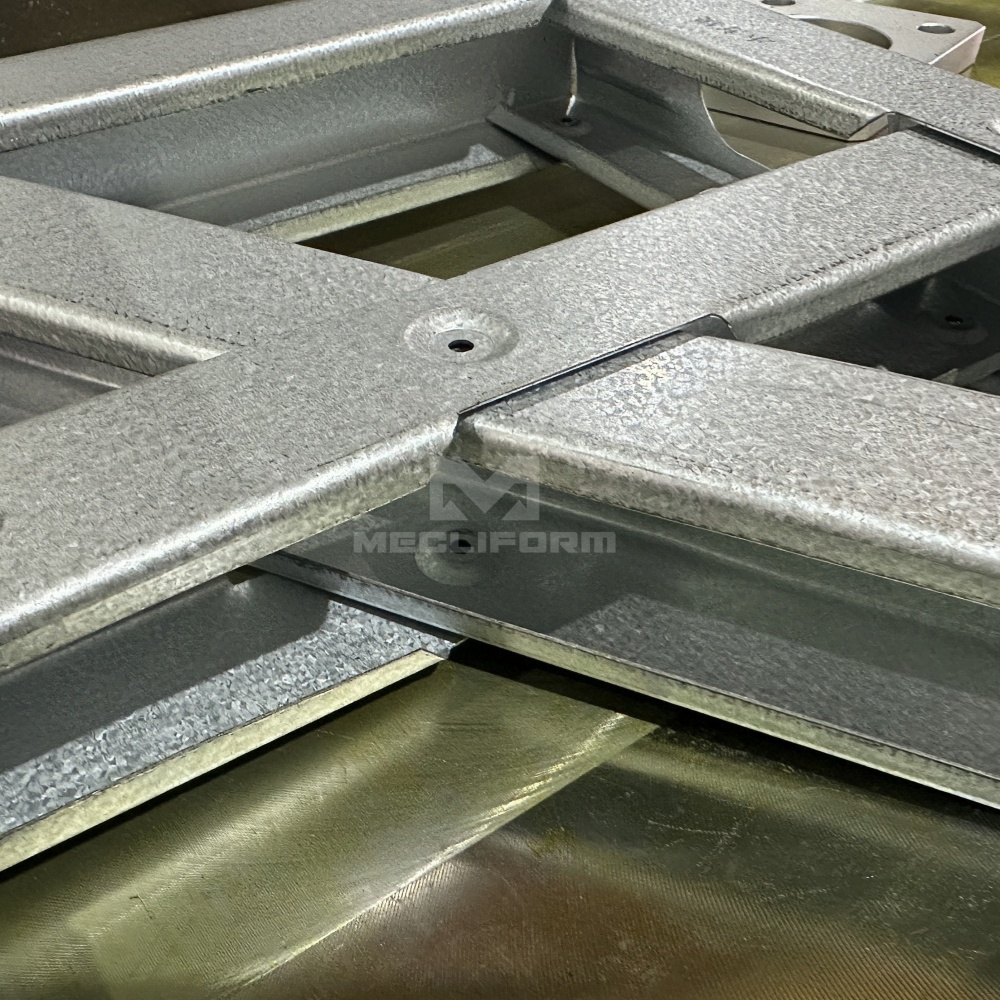

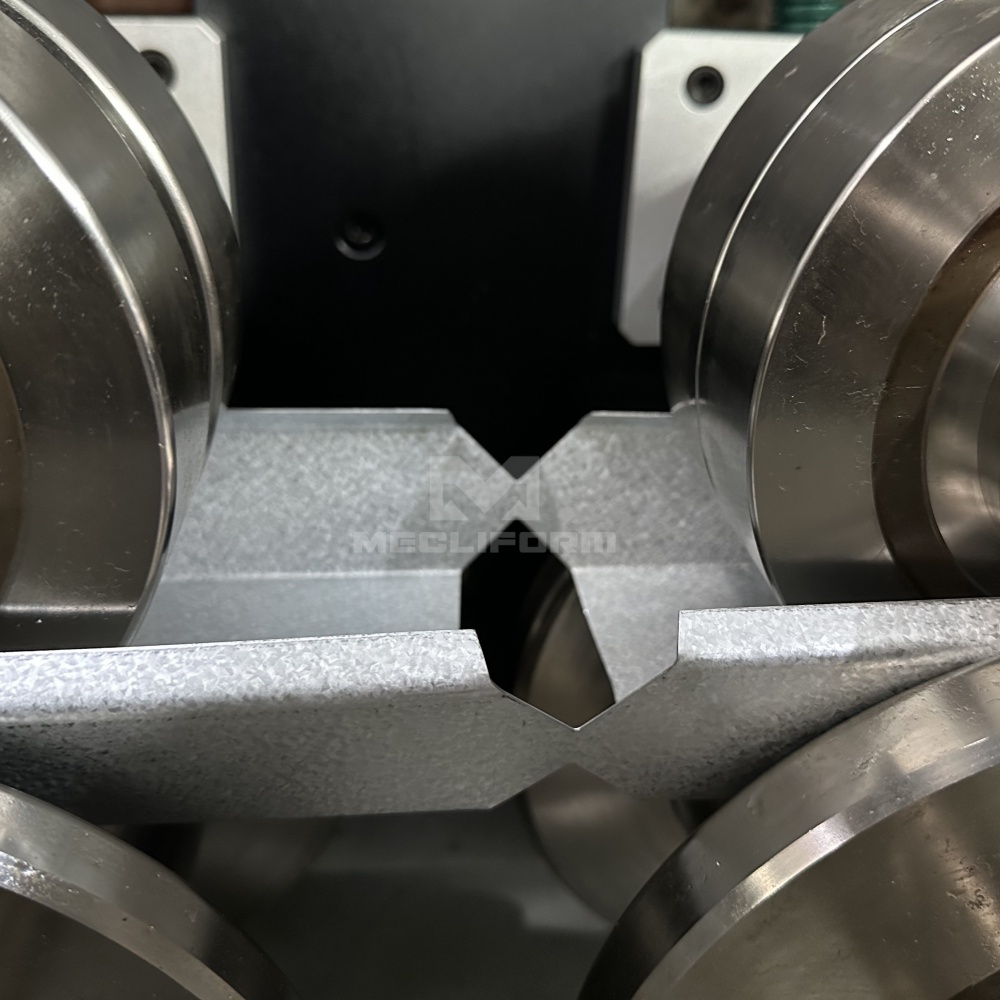

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.

Here are some main processes for how we manufacture the machines at workshop, from CNC machining to assembly.