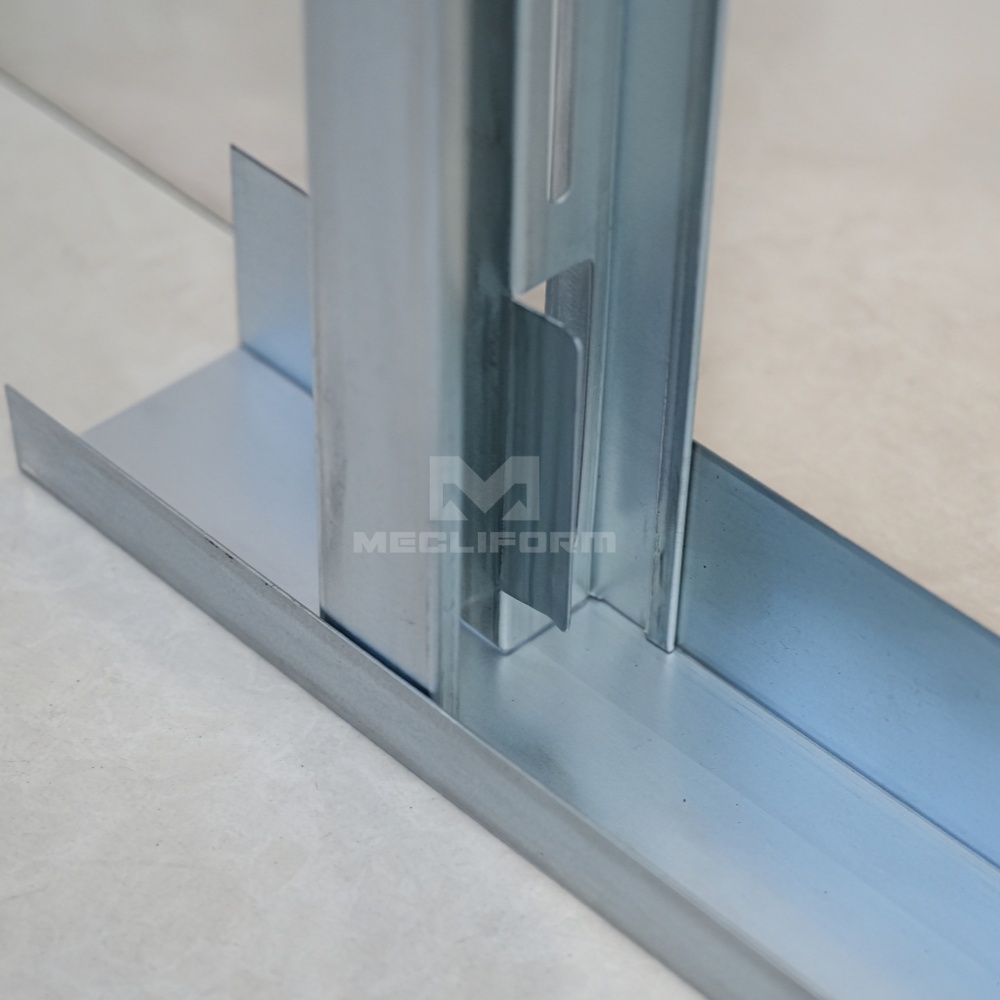

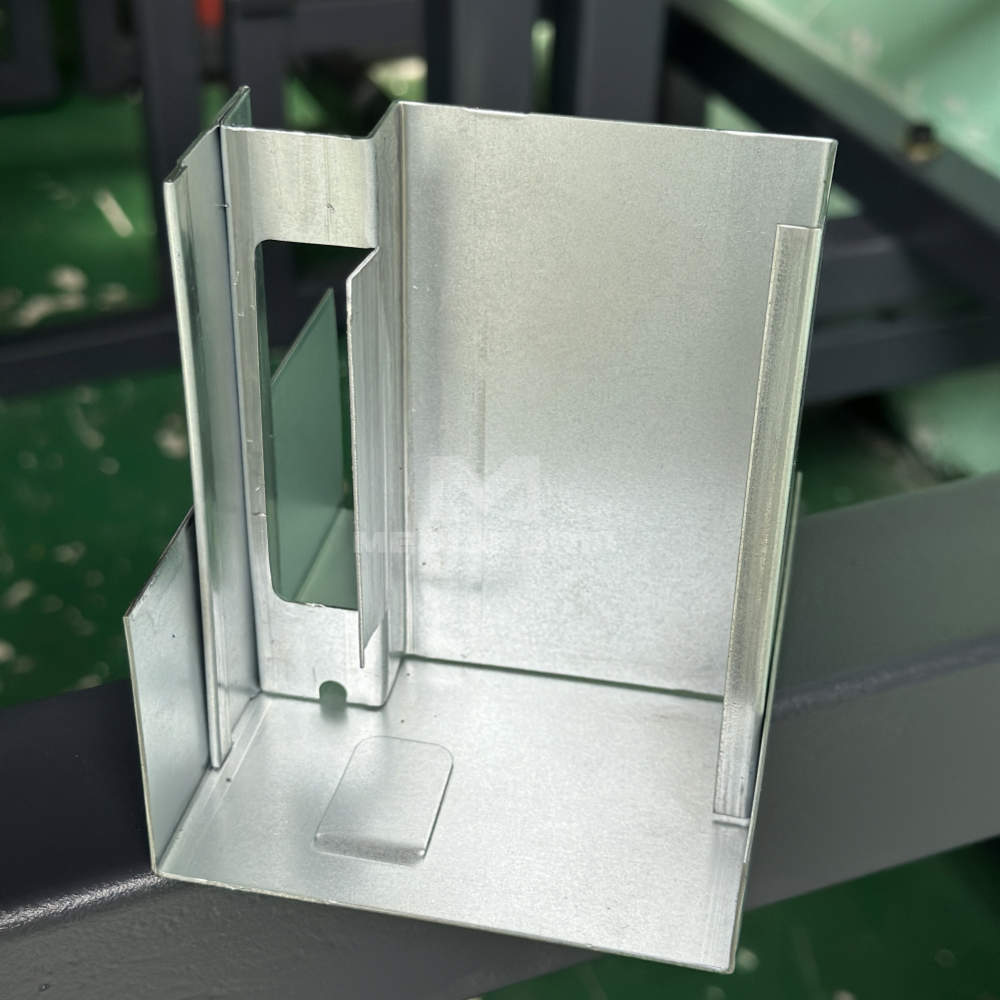

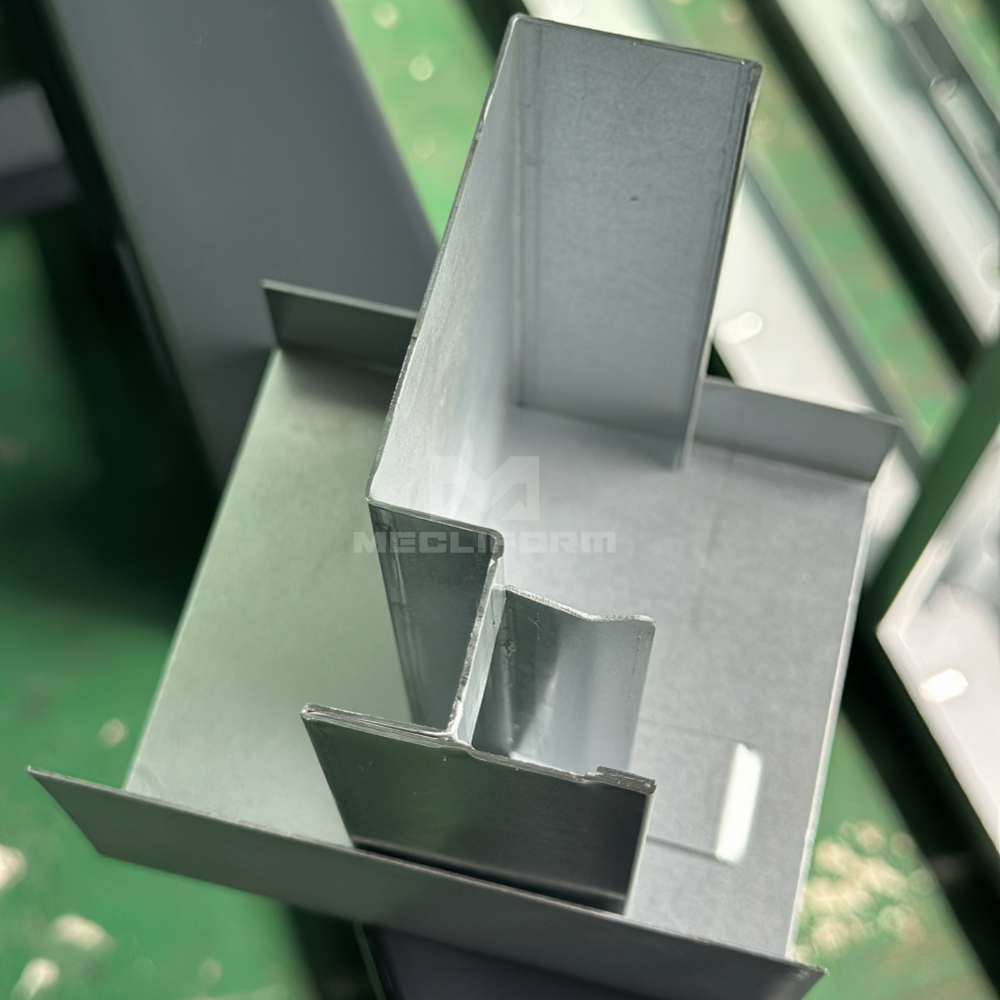

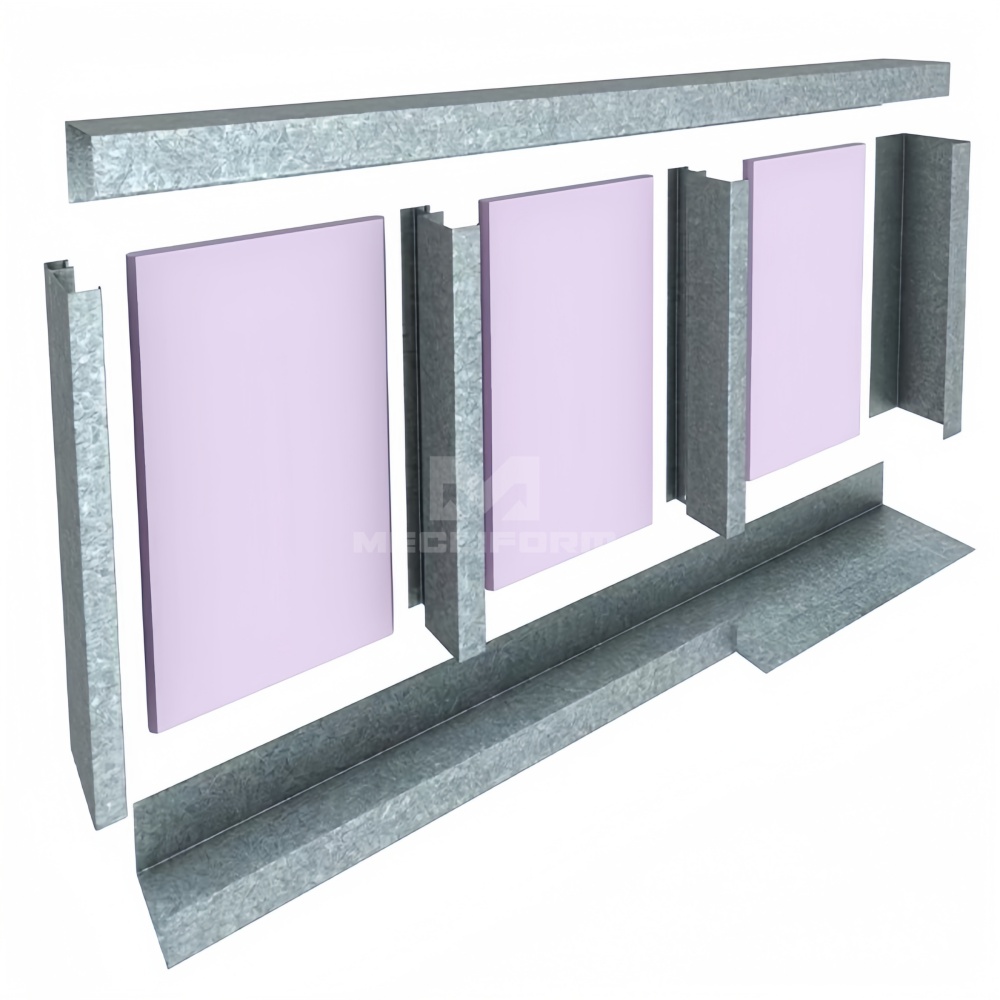

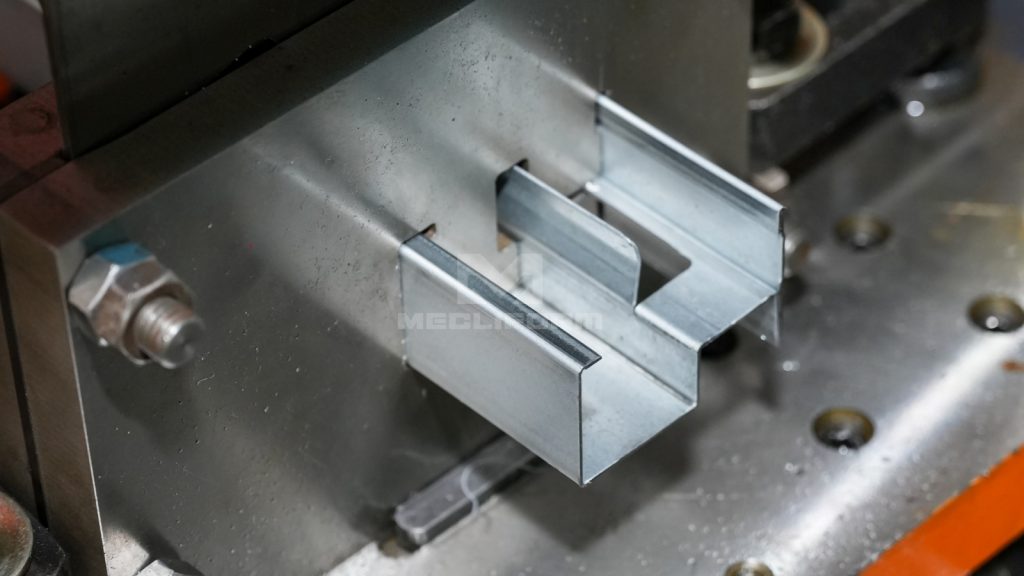

Shaftwall CT Stud is a type of metal stud used in the construction of shaftwalls, which are vertical enclosures in buildings that house plumbing, electrical, and ventilation systems. The CT Stud is specifically designed for use in shaftwall assemblies to provide support and stability for the enclosure. The Shaftwall CT Stud is made of galvanized steel, which provides rust and corrosion resistance, making it durable and long-lasting. It features a unique C-shaped design that allows for easy installation and bolting of the stud to the floor and ceiling, providing a secure connection for the shaftwall system. The CT Stud is also designed with pre-punched holes for easy attachment of drywall or other finishing materials, making it a versatile and efficient choice for shaftwall construction. Its lightweight and compact design make it easy to transport and handle on the job site, resulting in faster and more efficient installation. Overall, the Shaftwall CT Stud is a reliable and durable metal stud option for creating strong and stable shaftwalls in commercial and residential buildings.

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.