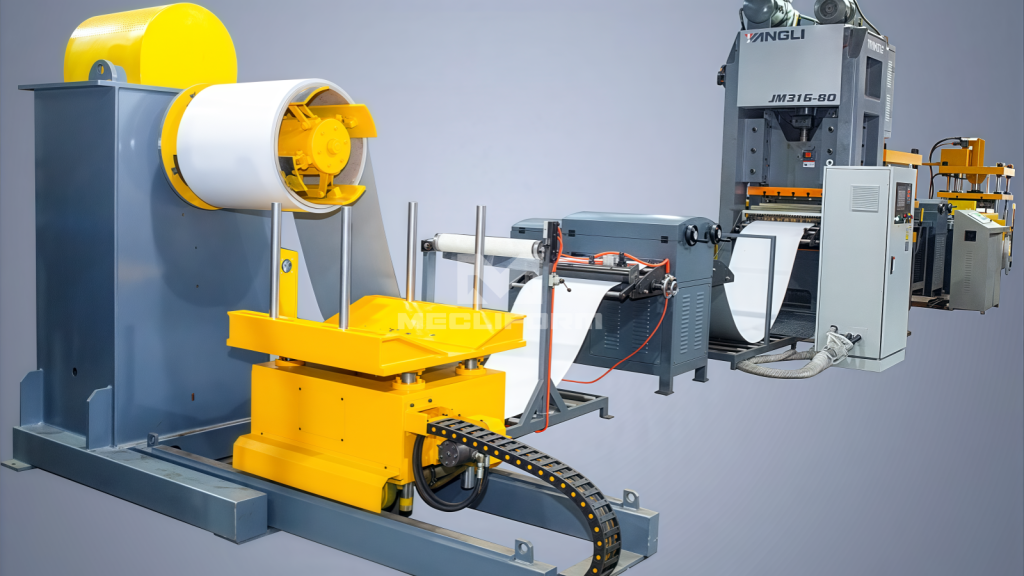

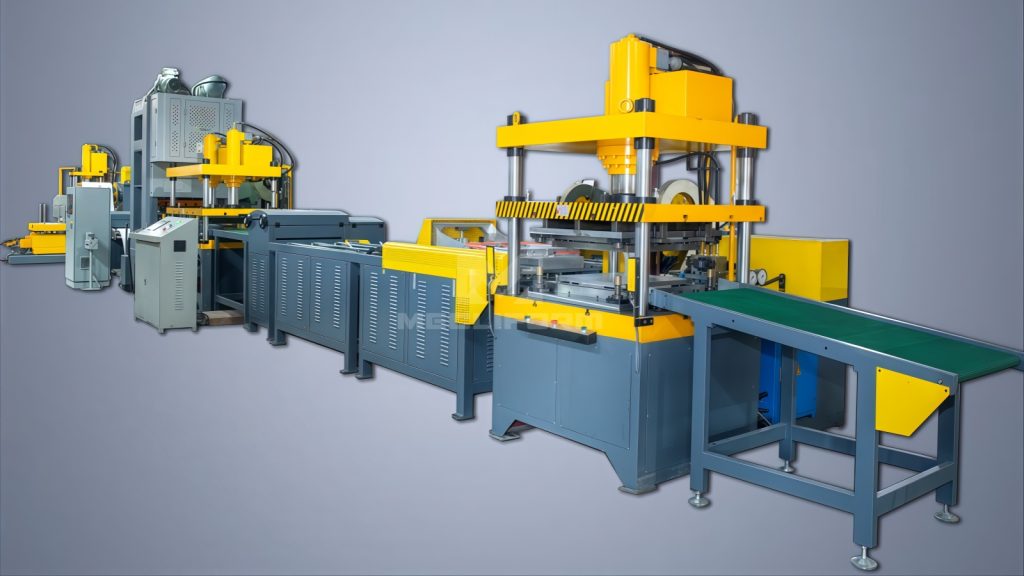

Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs. These machines are equipped with advanced features for cutting, forming, and finishing tiles with precision and efficiency.

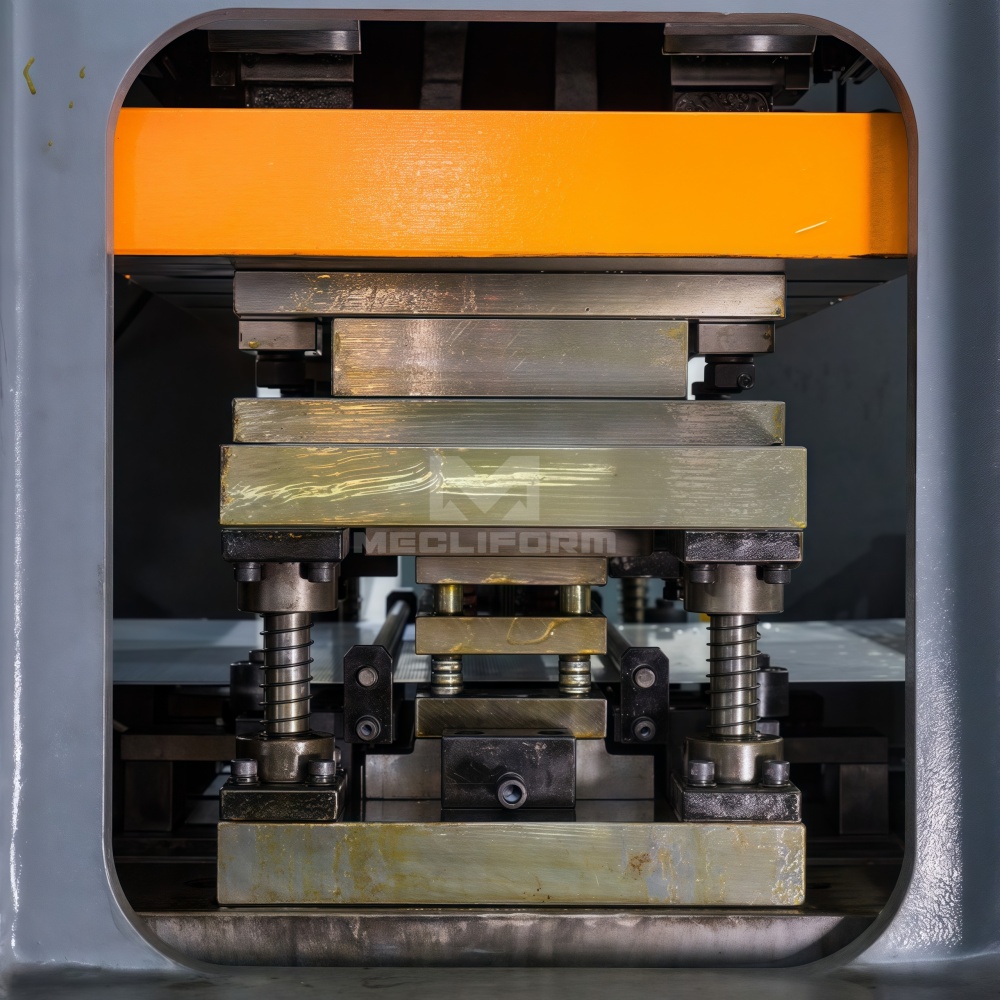

Perforation unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired holes.

Corner cutting unit is used to cut four corners of strips and cut to length before bending, one stroke for one piece.

Turn-over unit is used to turn another side of pre-cut sheet, and next step it will be carried by manipulator (pneumatic suction type) for bending.

Hydraulic Bending unit is used for bending the strips for ceiling tiles, clip-in type or lay-in type.

Here are some main processes for how we manufacture the machines at workshop, from CNC machining to assembly.