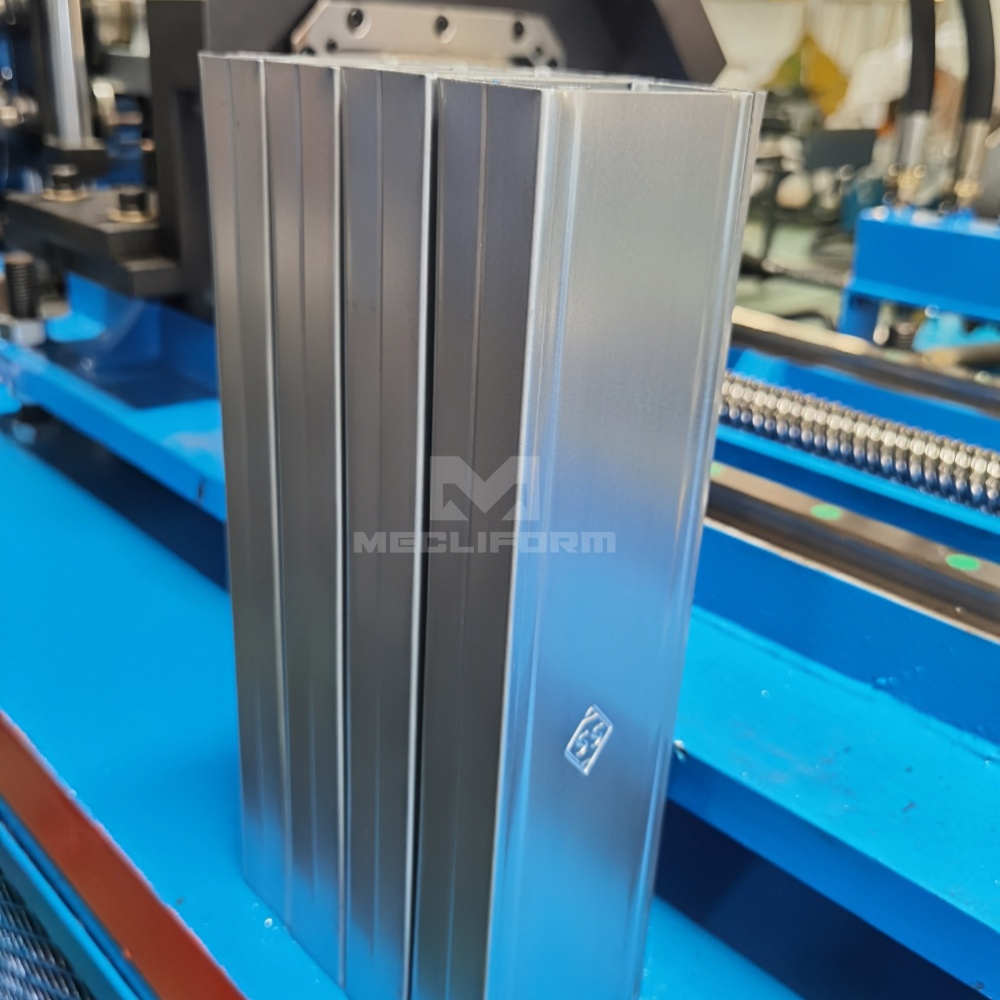

Drywall Stud and Track Production Line is a fully automated manufacturing system designed to produce high-quality metal studs and tracks used in drywall framing and partition systems. This efficient production line processes galvanized or pre-painted steel coils into precise C-shaped studs and U-shaped tracks with consistent dimensions, ensuring structural integrity and ease of installation in commercial and residential construction.

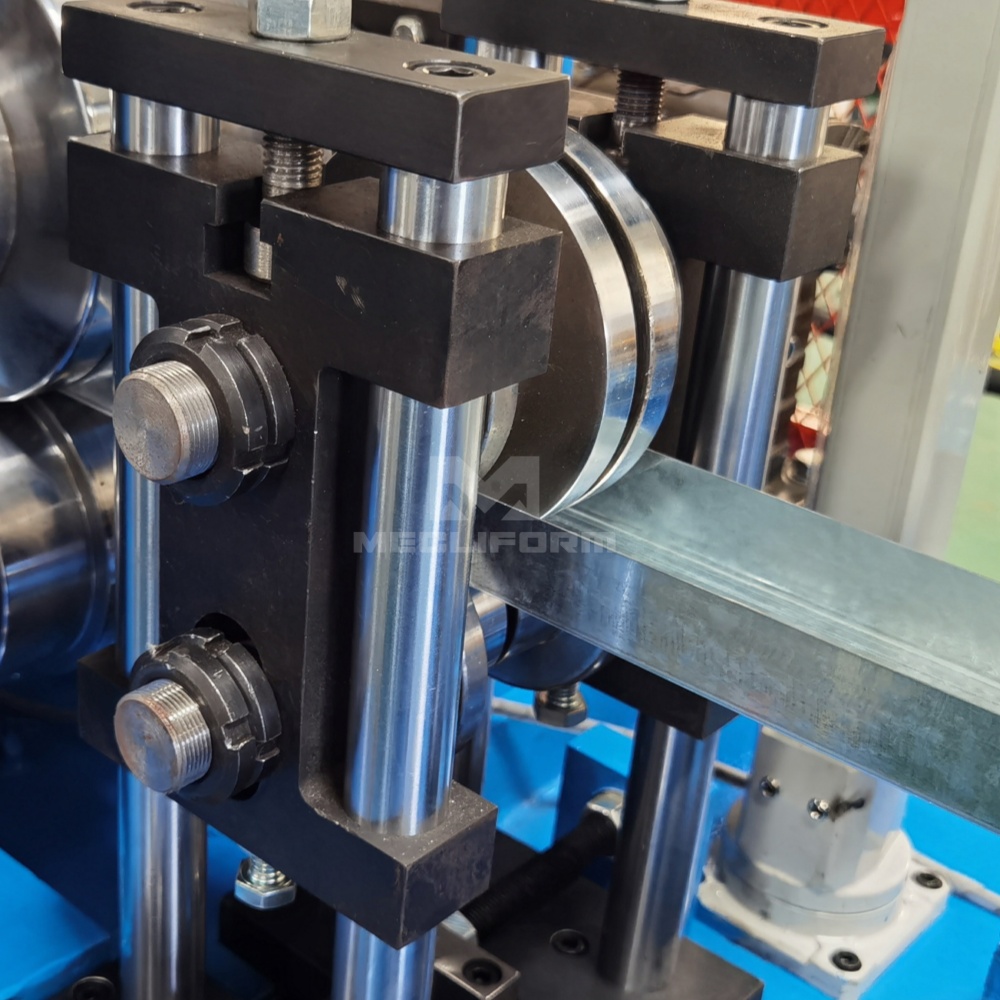

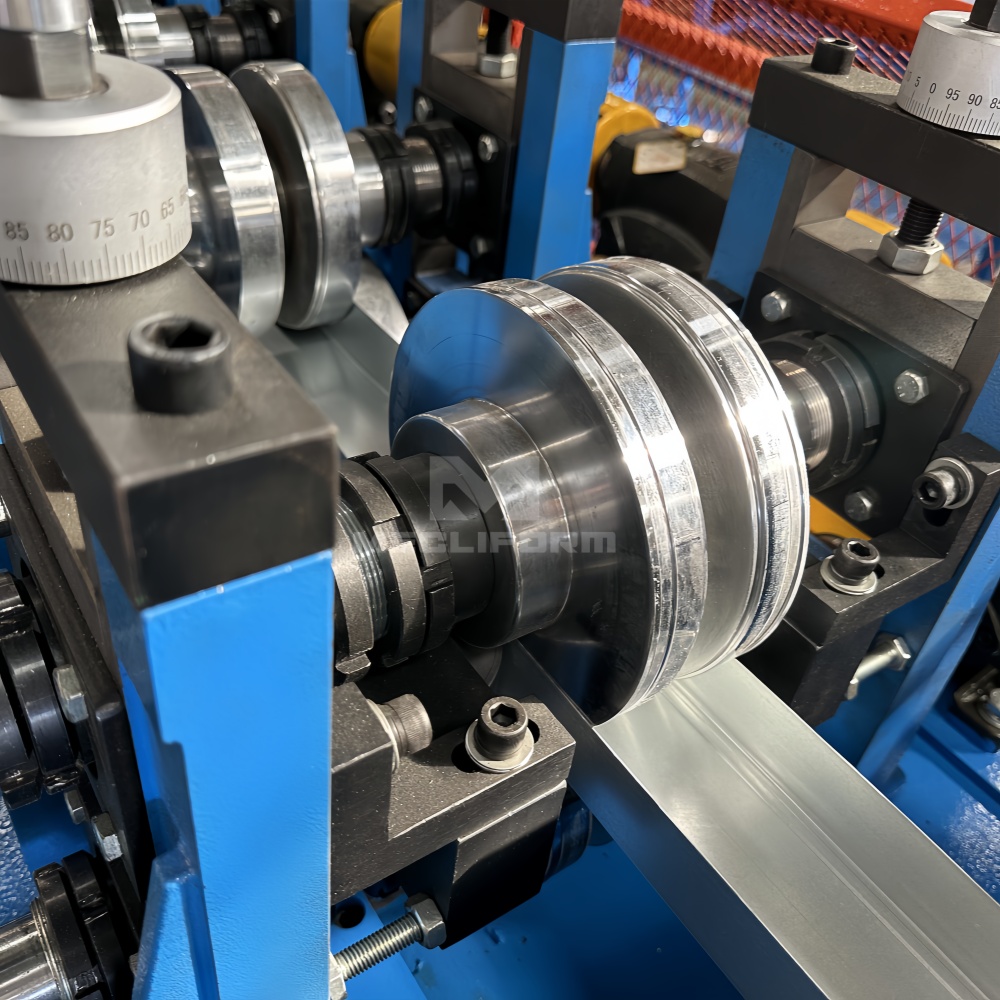

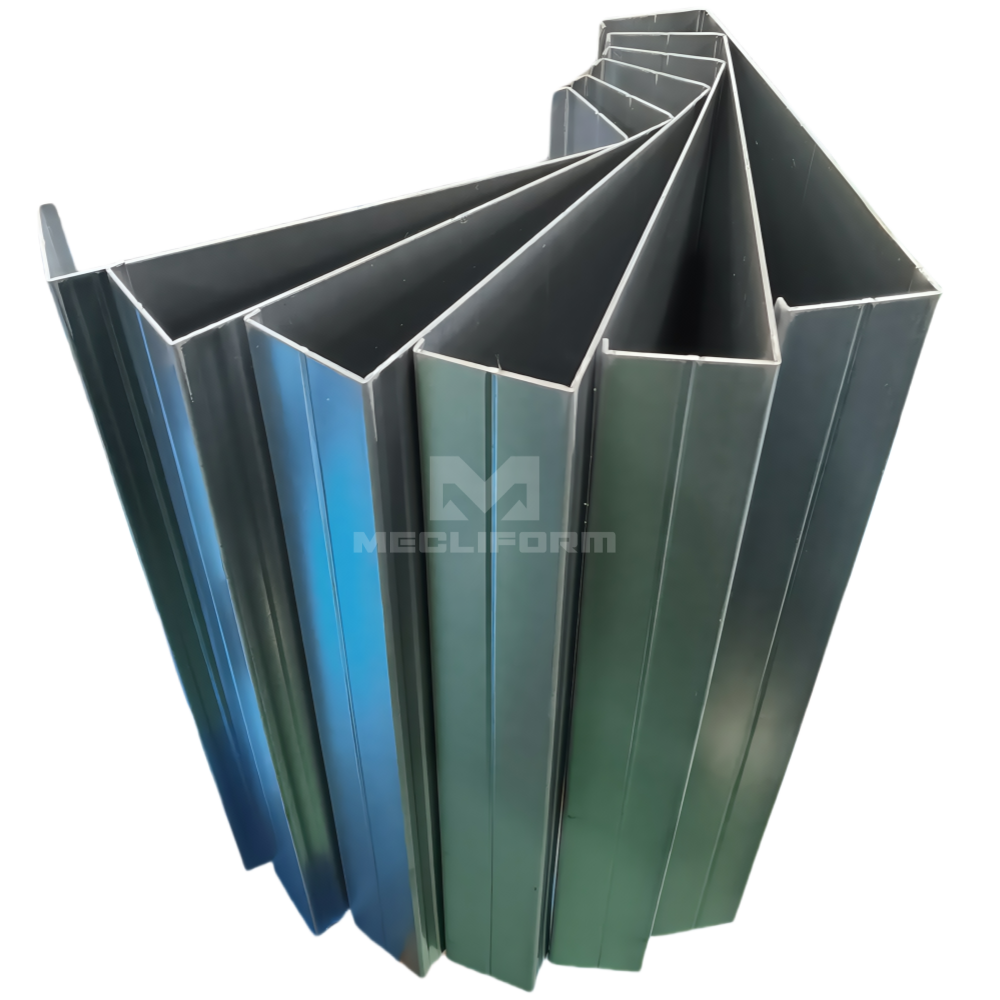

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. It’s multiple-size design by automatic change of profile widths.

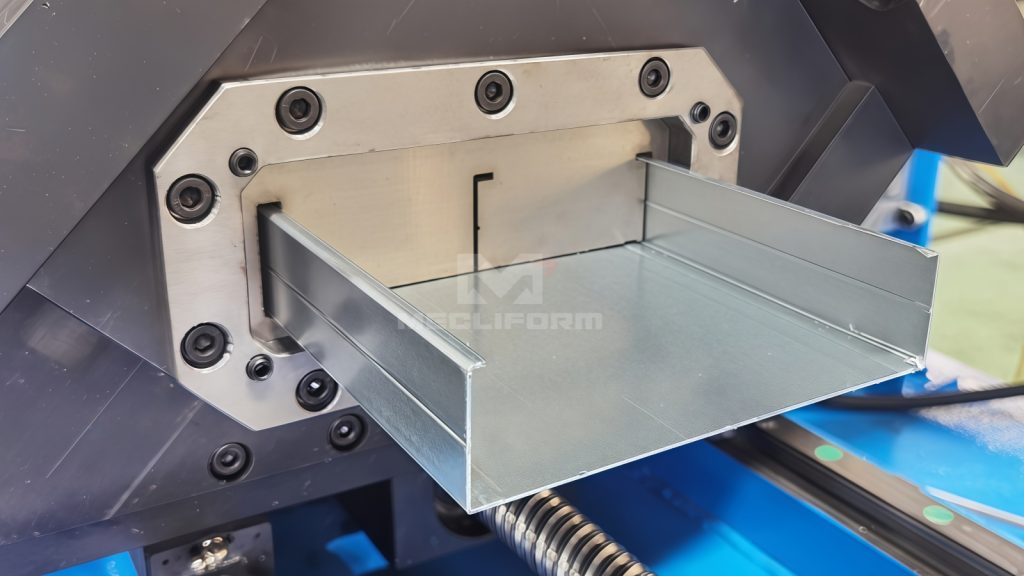

Hydraulic cutting unit is used to provide smooth and clean cuts, reducing the need for additional finishing work. It is typically operated by a control panel that allows the user to adjust the cutting speed and pressure according to the material being cut.