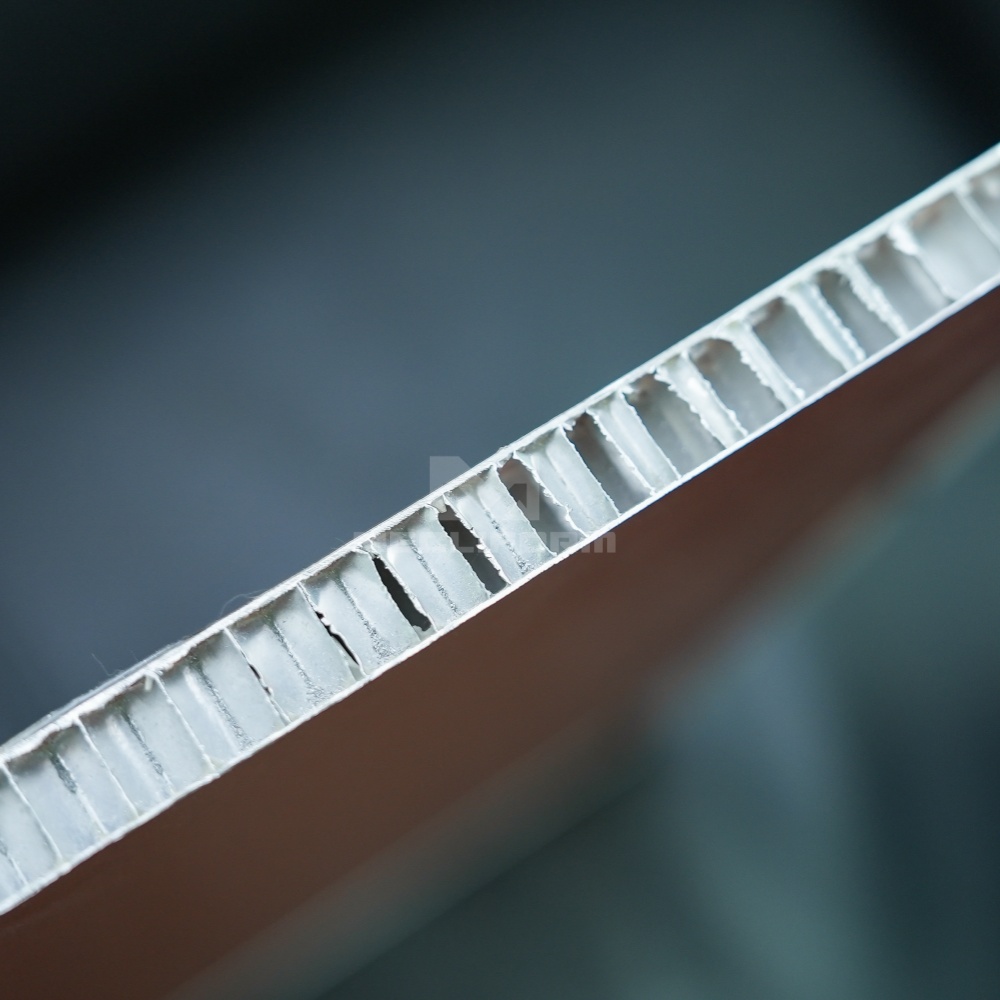

Our ceiling tile machines are capable of producing a wide range of ceiling tile profiles, including standard and custom designs, traditional tiles and honeycomb core types. These machines are equipped with advanced features for cutting, forming, and finishing tiles with precision and efficiency.

Notching unit is used to notch before roll forming. It typically consists of a notching tool (left and right) that is propelled with force through the material to create the desired notch for further corner bending.

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.

Servo bending unit utilizes servo motor technology to control the bending process with precision and consistency. This unit is equipped with adjustable settings and easily programmable features, allowing for a wide range of bending angles and shapes to be achieved.

Auto assembly unit consists of a series of equipment, including glue sprayer, alignment unit, combination unit, turn-over unit, auto stacking unit, and cold presses.