The cable tray production line is a fully automated manufacturing system designed to produce high-quality cable trays efficiently and cost-effectively. This integrated line transforms raw materials (steel or aluminum coils) into finished cable trays through a series of precision processes, including cutting, roll forming, punching, bending, and welding (if required). It ensures consistent output, reduced labor costs, and high-speed production for various cable tray types, such as ladder-type, perforated, and trunking systems.

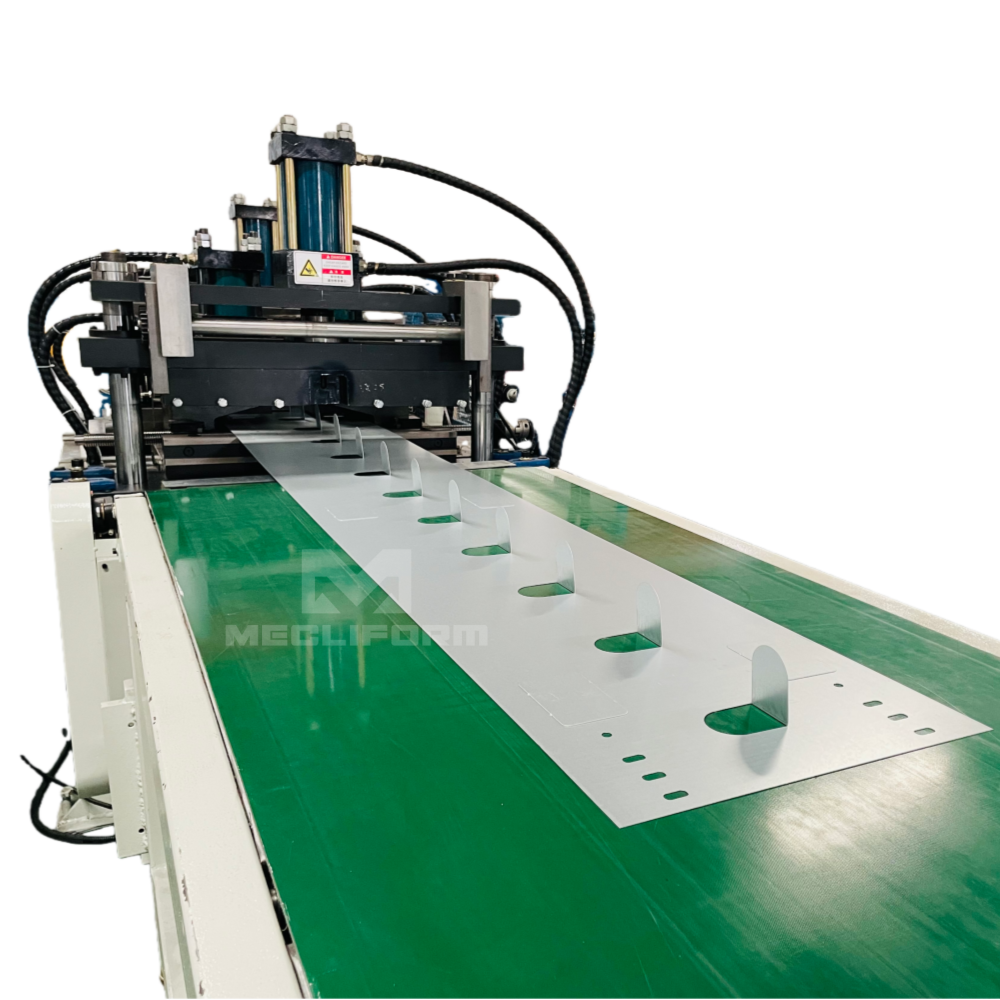

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

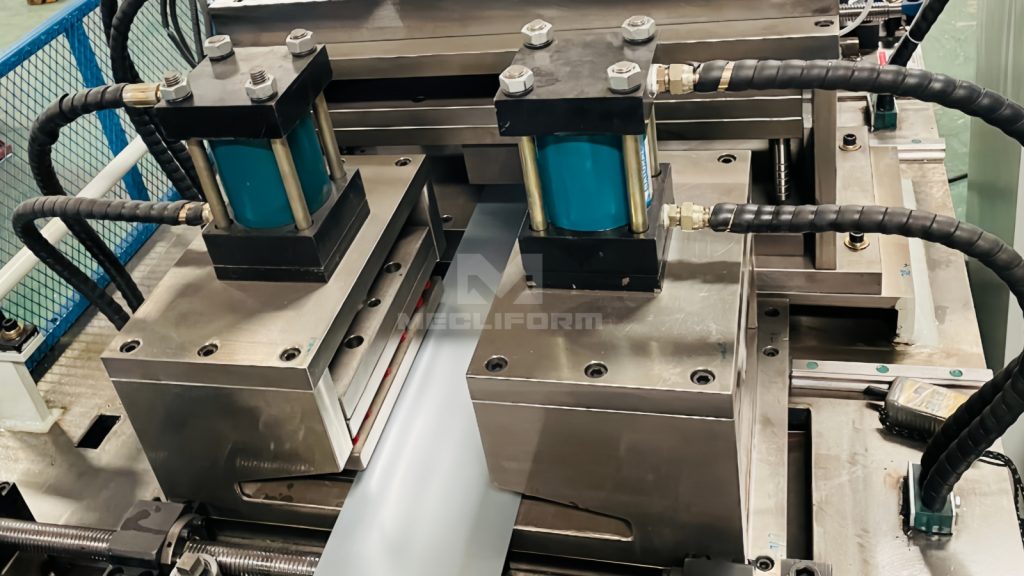

Pre-cut unit is a key component of an automated cable tray production line, designed to precisely cut raw materials (such as steel or aluminum coils) into predetermined lengths before forming. It reduces material waste and optimizing workflow.

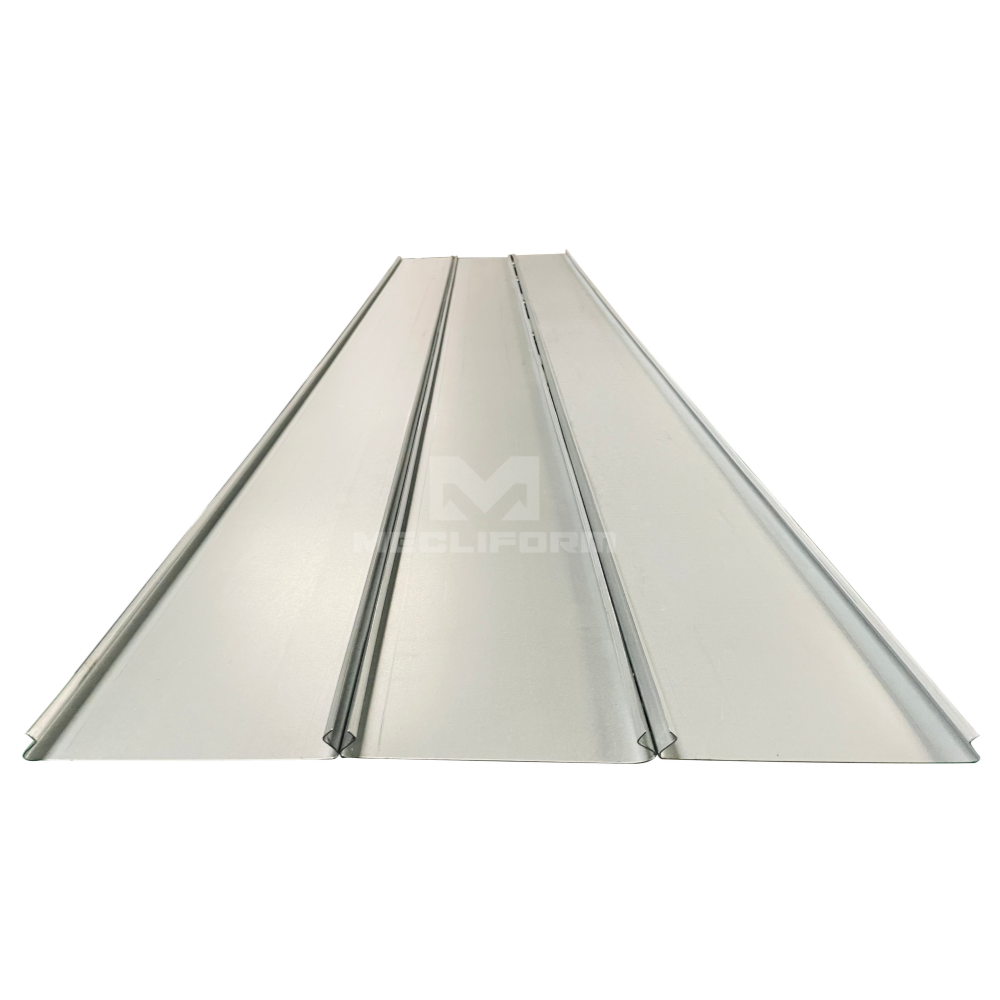

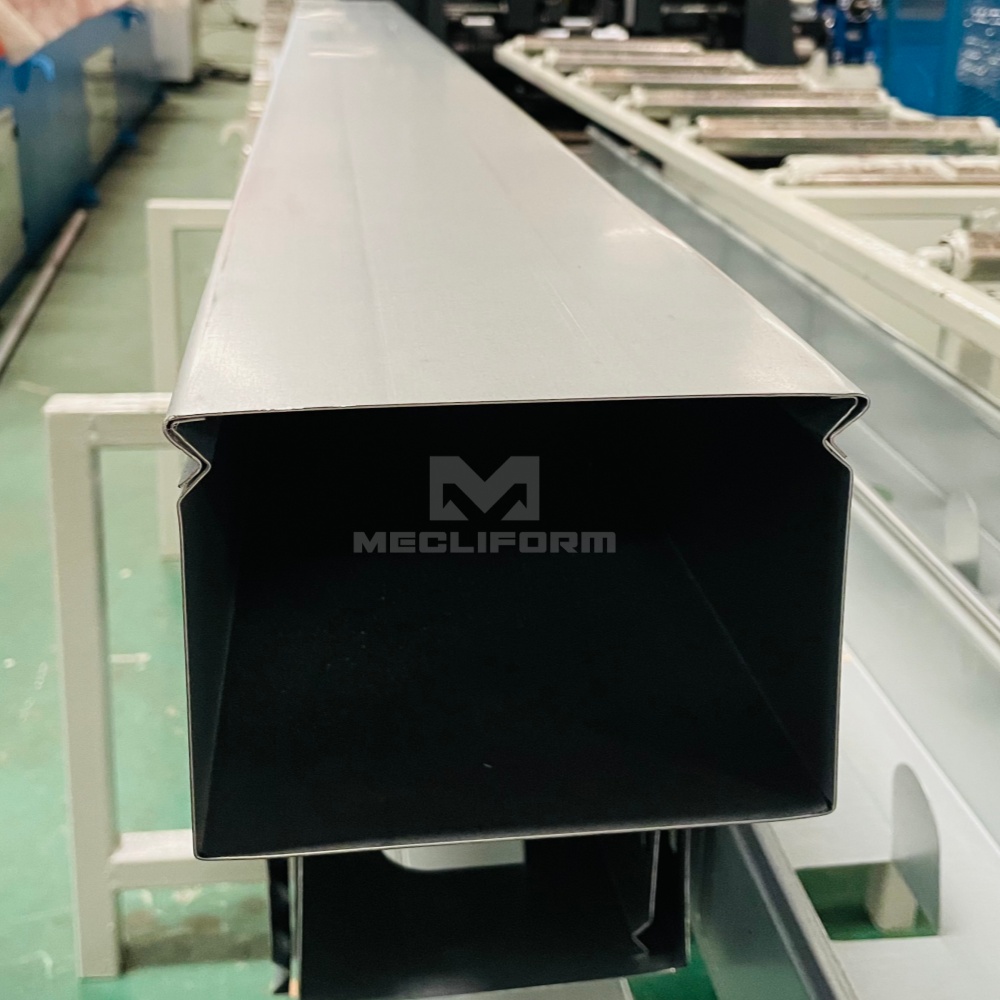

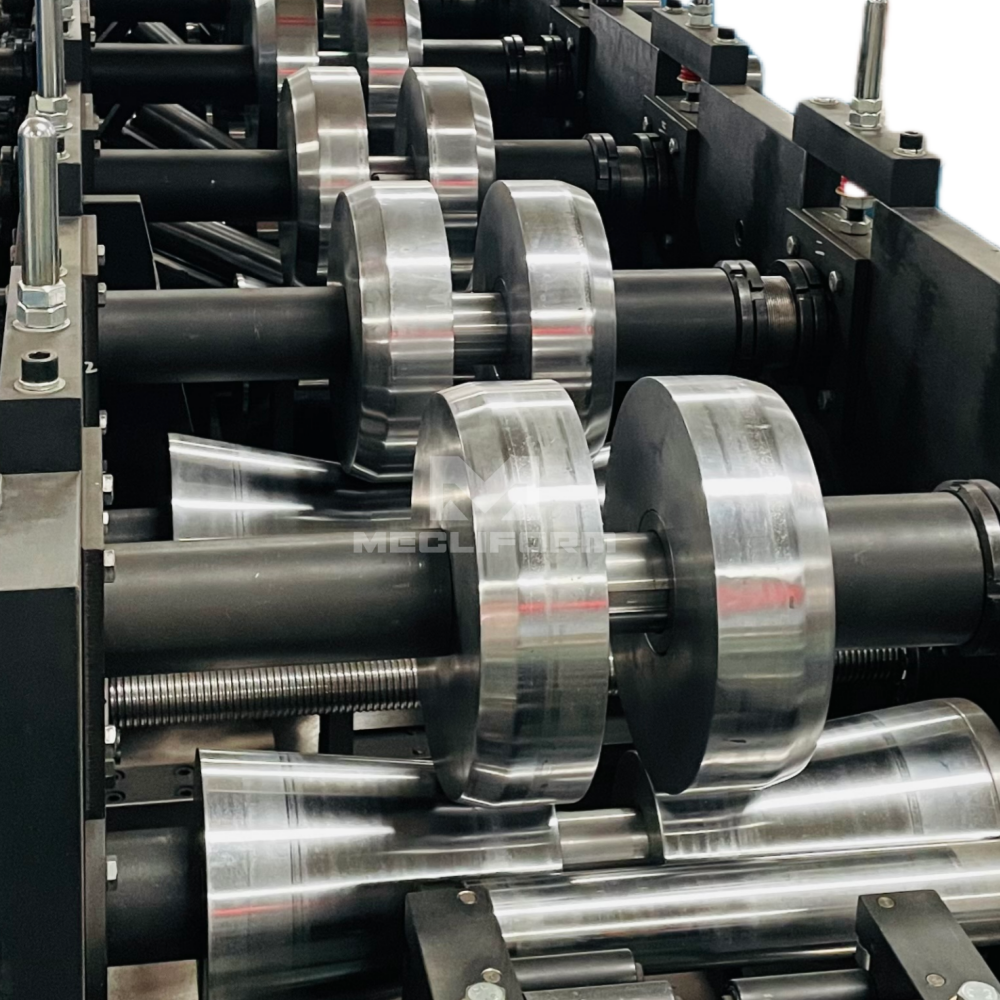

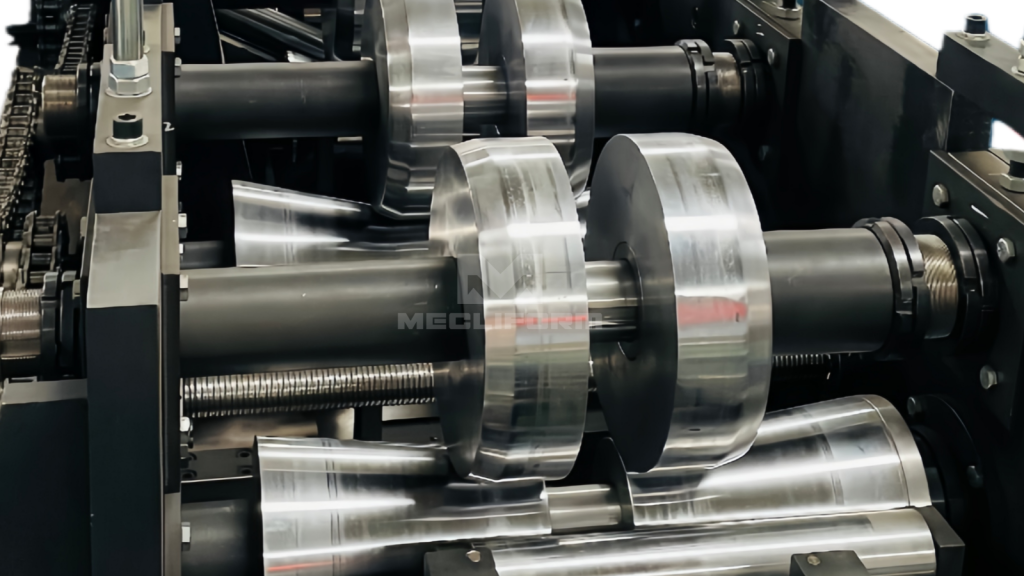

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape.