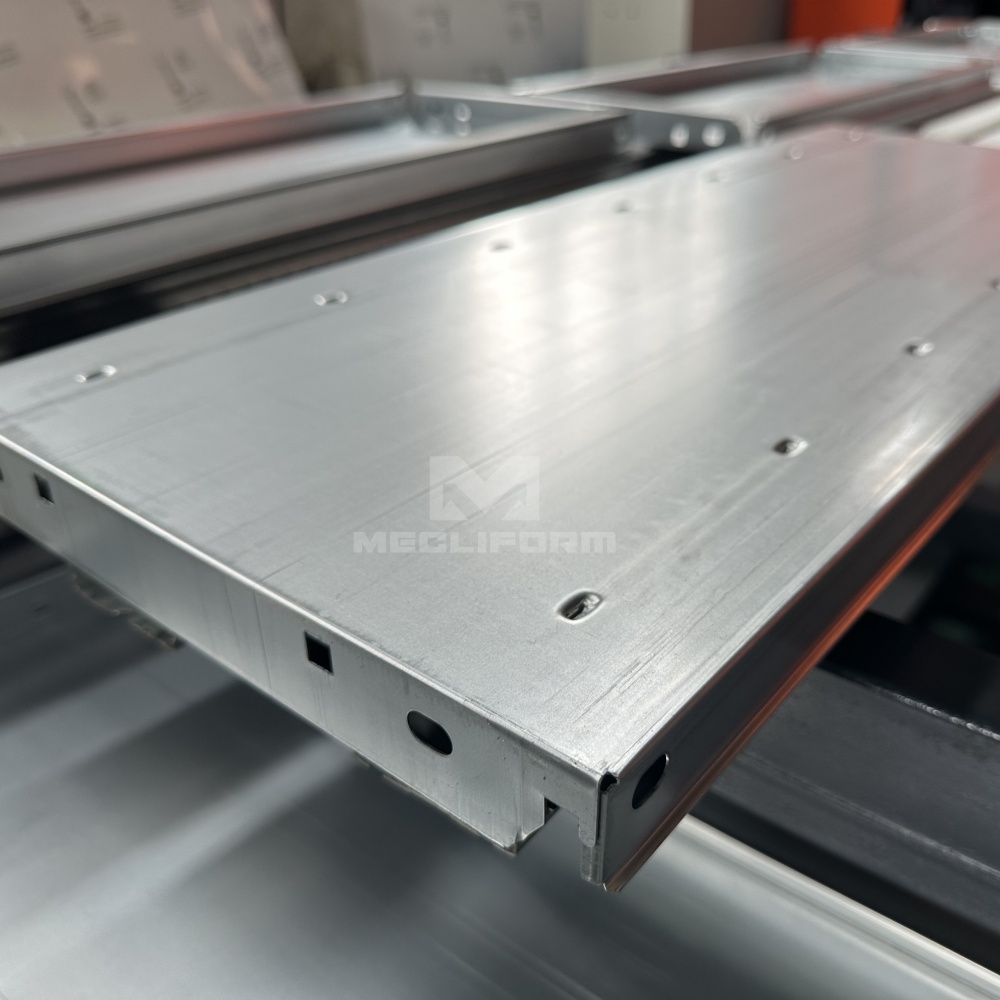

Our storage and logistics machinery includes roll formers designed to produce shelving, racking, and other storage solutions for warehouses, distribution centers, and manufacturing facilities. These machines are built to withstand heavy use and deliver precise, consistent results. These machines are versatile and can be easily adjusted to create different profiles and sizes to meet specific project requirements.

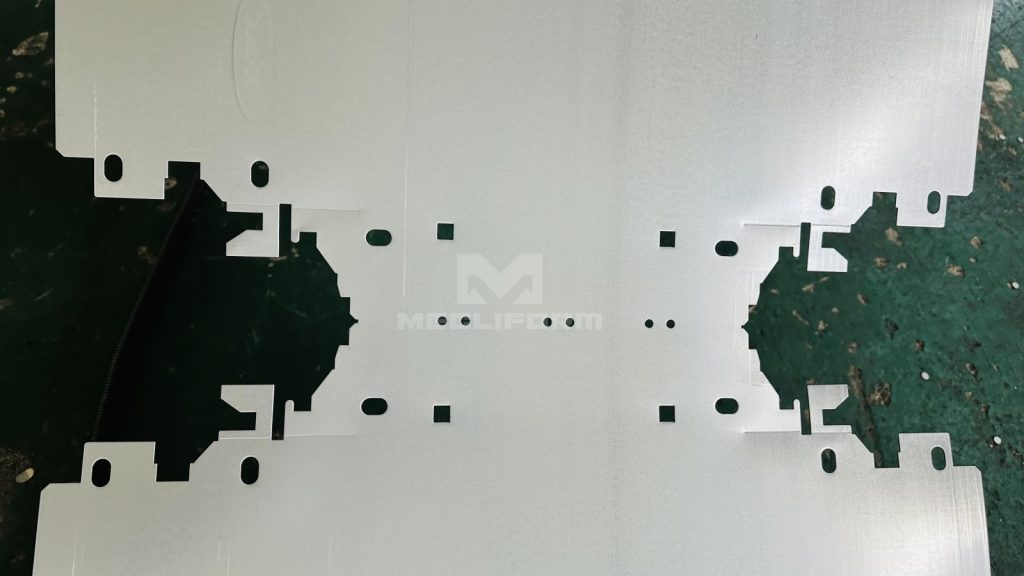

Punching unit is used to punch holes before roll forming. It typically consists of a metal tool that is propelled with force through the material to create the desired hole or shape.

Roll former is used to create uniform, continuous bends in metal materials. It works by passing a strip of material through a series of rollers that gradually bend and form the material into its desired shape. Width is auto adjustable.

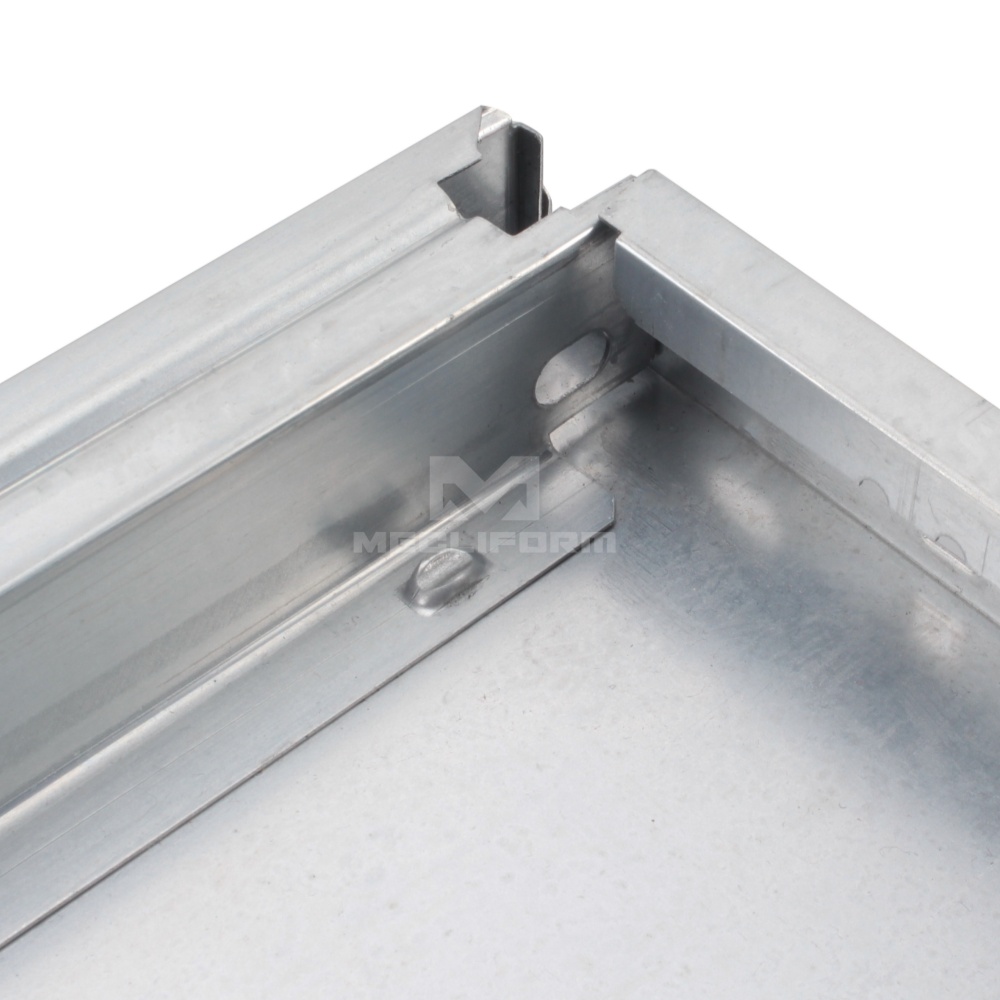

Clinching unit is used to securely join two pieces of material together without the use of additional fasteners such as screws, rivets, or welding. It works by deforming the materials being joined using pressure and/or fast rotation, creating a strong and durable connection.

Servo bending unit utilizes servo motor technology to control the bending process with precision and consistency. This unit is equipped with adjustable settings and easily programmable features, allowing for a wide range of bending angles and shapes to be achieved.